Qt6-15 Block Making Machine Cement Lego Bricks Hydraulic Fly Ash Brick Solid Block Making Machine Manufacturer China

Qingdao HF Machinery Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Cycle Time:15-20s

- Pallet Size:950*950mm

Base Info

- Model NO.:Qt6-15

- Host Machine Weight:7900kg

- Vibration Form:Platform Vibration

- Color:Optional

- Warranty:1 Year

- Voltage:220-240V

- Transport Package:Standard Export Packing

- Specification:7100x1500x3000mm

- Trademark:HF

- Origin:Shandong, China

- HS Code:847480909

- Production Capacity:60sets,Month

Description

Basic Info.

Model NO. Qt6-15 Host Machine Weight 7900kg Vibration Form Platform Vibration Color Optional Warranty 1 Year Voltage 220-240V Transport Package Standard Export Packing Specification 7100x1500x3000mm Trademark HF Origin Shandong, China HS Code 847480909 Production Capacity 60sets/MonthProduct Description

QT6-15 Fully Automatic Brick Making Machine

1-> QT6-15 Fully Automatic Stacking Brick Making Machine Plant use PLC intelligent control, make the man-machine interface

1-> QT6-15 Fully Automatic Stacking Brick Making Machine Plant use PLC intelligent control, make the man-machine interfaceas true, control system equipped with complete logic control, production program, malfunction diagnosis system and remote

control function.

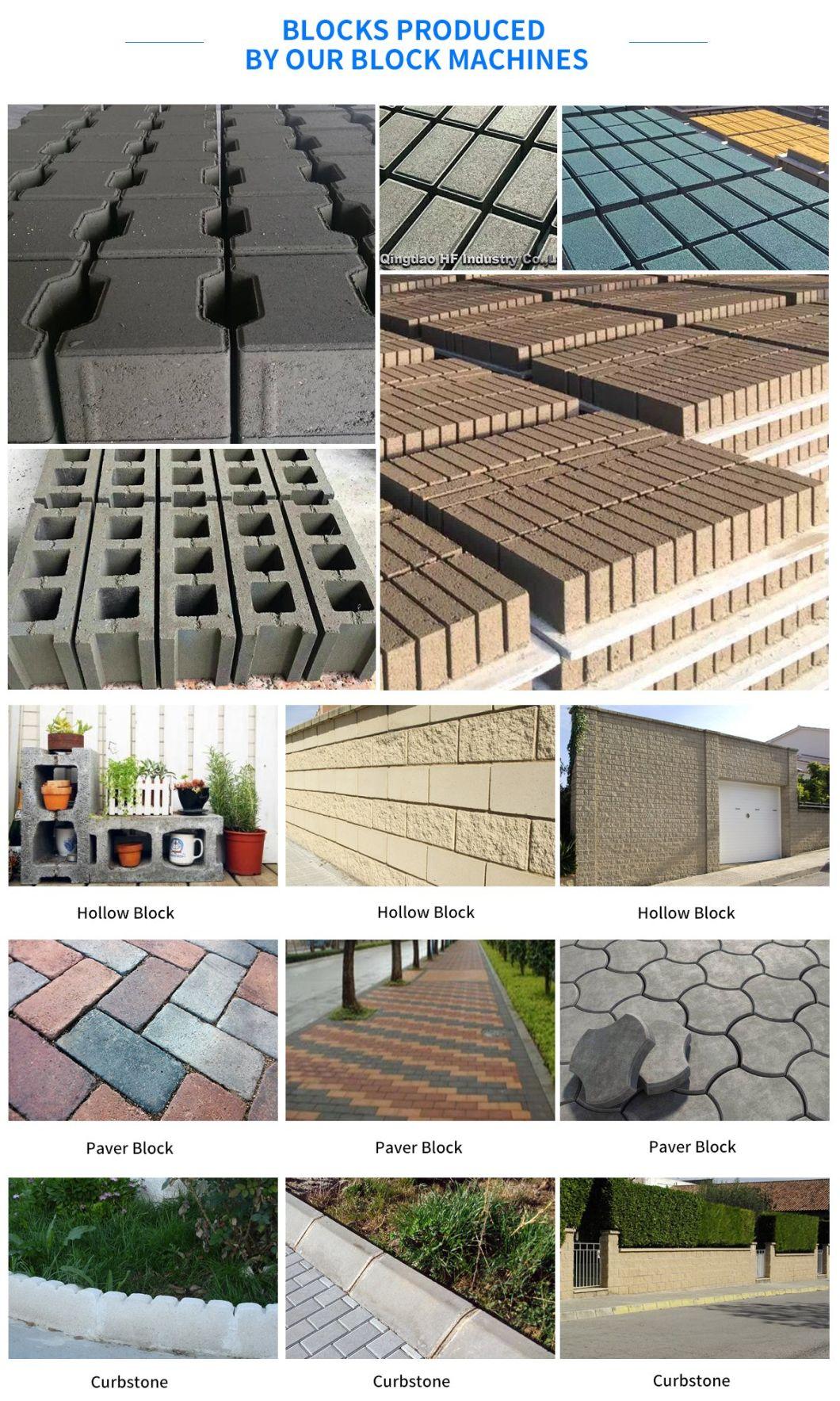

2- > Can produce the paver block with or without color on the surface, if need color, should use the face-color material feeding device.

3- > Through mold-releasing oil cylinder, the mold box was locked into the vibration table with high rigidity to reach the synchronous

vibration, so that the concrete can be fluidified and exhausted in two or three seconds to ensure the high-density, especially suitable

to produce the standard blocks, which can be piled up immediately so that the pallet investment can be saved directly.

4- > The unique forcing charge system can make use of various kinds of industrial waste and material such as coal ash, cement, sand,

stone, slag, and so on. The machine can severs several purposes and produce various specification standard bricks, concrete blocks,

porous blocks, paving bricks etc just changing the mold.

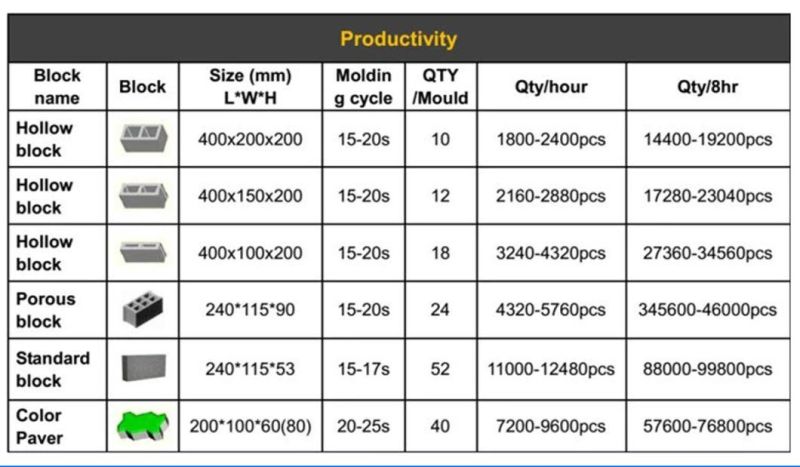

Block Capacity

Block Capacity  Our Advantages

Our Advantages 1. PLC control System; we select original Siemens PLC combine with independently develop machinecontrol program , assure stable and high-efficiency workingstatus.

1. PLC control System; we select original Siemens PLC combine with independently develop machinecontrol program , assure stable and high-efficiency workingstatus. 2. Switches : Adopt Japan Omron and France schneider brand ,

3. Motor : we will use Siemens or ABB brand .

4. Hydraulic system : Double proportional hydraulic valve for smooth operation and long service life

5. Mould: Mnaganese steeel, deal with advanced heat treatment device assure longer mould life.

and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58HRC so that the mould can be used more than 100 thousand times.

6. Spare parts: follow the machine to shipment, we supply suitable wearing parts ,the after-sale services will be faster.

Our Customer

Our Company

Our Company QINGDAO HF INDUSTRY CO.,LTD is the professional manufacturer and exporter for block machine technology. Our company is located in Qingdao city Shandong Province and our factory has three manufacturing bases that cover an area of 500 acres and a plant construction area of 100,000 square meters. We are always developing advanced products to international standards

QINGDAO HF INDUSTRY CO.,LTD is the professional manufacturer and exporter for block machine technology. Our company is located in Qingdao city Shandong Province and our factory has three manufacturing bases that cover an area of 500 acres and a plant construction area of 100,000 square meters. We are always developing advanced products to international standardsto meet consumer demands.We had exported to more than 116 countries from the Philippines, Russia, Egypt, South Africa, Ghana, Oman, India, Armenia, Israel, Chile etc. and have an exceptional high reputation from our customers. We cooperate with SIEMENS for Motors and PLC intelligent control system, Schneider electrical equipment and YUKEN for the hydraulic operations to insure our machines have the highest quality standrads with a stable working status.We have more than 50 technician to ensure superior installations and after sale service to assist customer to install the machine and perfrom the proper training abroad. We warmly welcome customers from all over the world come to visit our factory and discuss long term cooperation.