Plastic Extrusion Machine/WPC Flooring Production Line

Wuxi Boyu Plastic Machinery Co., Ltd.- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

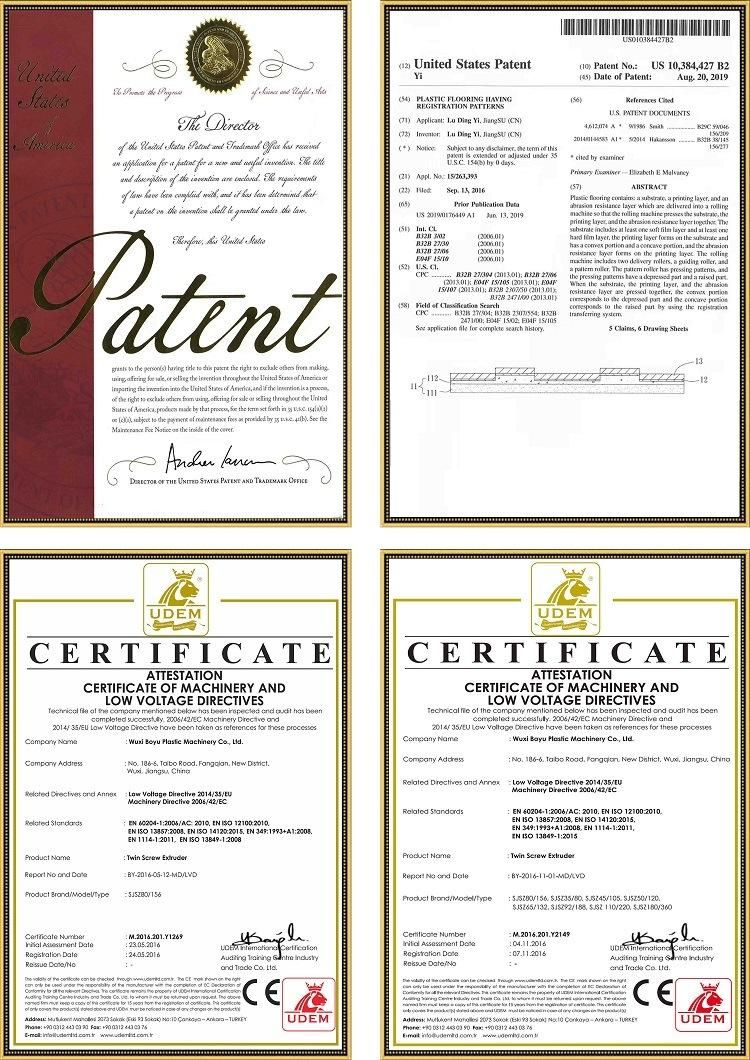

- Certification:CE, ISO

- Condition:New

- Customized:Customized

Base Info

- Model NO.:SJSZ80,156 SJSZ92,188

- Type:Sheet Extruder

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:PVC Film

- Specification:CE SGS

- Trademark:BOYU

- Origin:Wuxi

- HS Code:8477209000

- Production Capacity:20,Month

Description

Basic Info.

Model NO. SJSZ80/156 SJSZ92/188 Type Sheet Extruder Plastic Processed PVC Feeding Mode One Feed Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package PVC Film Specification CE SGS Trademark BOYU Origin Wuxi HS Code 8477209000 Production Capacity 20/MonthProduct Description

WPC PVC Foam Board Making Machine/Extrusion Line

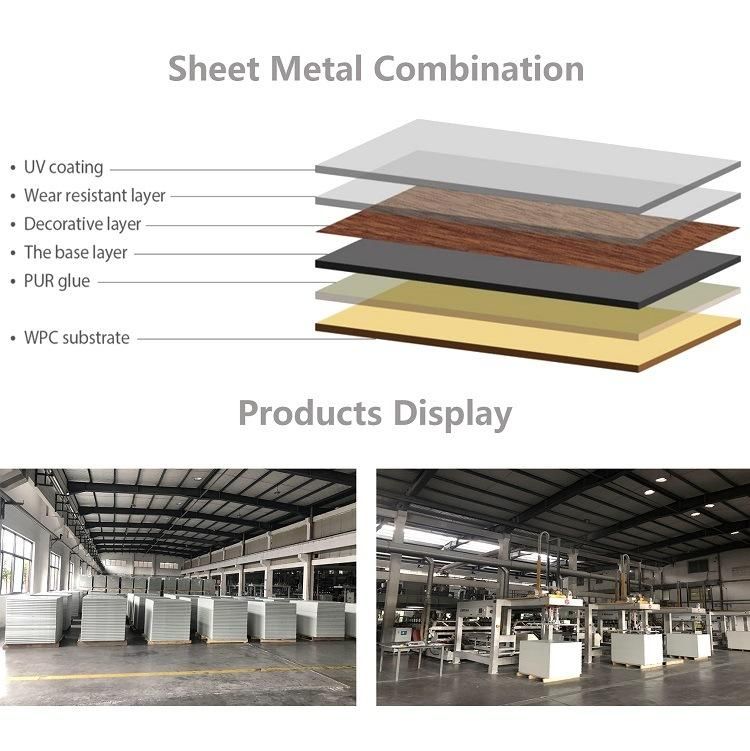

WPC/PVC Foam Flooring Base Sheet is a new and high-tech environmental protection material. It is the product of the mixing pvc resin and processing agent going through the extruding mould. PVC floor substrate board has the properties and features of non-toxic, no smell, anti-corrision, anti- weathering, waterproof etc. It is the perfect substitute for wood.

WPC/PVC Foam Flooring Base Sheet can be worked with the tools for wood material. It's easy for sawing, drilling, nailing, bonding and planning. Meanwhile, It is a kind of durable indoor and outdoor waterproof and anti-corrosion building material with excellent performance.

I. Basic Information:

Brand Name: BOYU

Screw Design: Conical double screw

Model Number: SJSZ 80/156

Voltage: 380-440V

Main Motor Power: 75kw

Capacity: 350kg/h ~ 400kg/h

Dimension (L*W*H): 23m*3m*3m

Weight: 18t

Packaging Details: PE wrapping film, fumigating wooden cases.

Delivery Details: 30 working days.

2. Product Configuration:

1) Main motor: SIEMENS BEIDE

2) Contactor: SIEMENS

3) Auxiliary relay: SCHNEIDER or DELIXI

4) Temperature control system: DELTA PLC Touch Screen Control System

5) Inverter: ABB

6) All Extruder by the DELTA PLC Controlled.

3. Production Introduction:

| Item | Foam PVC board |

| Origin | Wuxi, China |

| Introduction | PVC Foam Board is the new man-made material, the main component is PVC, it has the fine chemical stability, anti-corrosive and high intensity, it can be the substitute of wood, it is widely used in the building, advertisement and decoration. |

| Thickness | 1-30mm |

| Length | As your request |

| Density | 0.35-0.8g/cm3 |

| Size | 1220*2440mm,1560*3050,2050*3050mm |

| Color | White, black, red, blue, yellow, green, gray, or as your request. |

| Applications | 1.Building outdoor wall board, indoor decoration board, decorative Wall Panel, furniture Board, cupboard, partition board in office and house. 2.Advertisement Board, screen printing, flat solvent printing, engraving, billboard and exhibition display. 3.Chemical anti-corrosion project, special cold project, environmental protection. 4. Indoor flooring base board. |

| Features | 1. Waterproofing. 2. Fire retardant and self-extinguishing. 3. Heat preservation. 4. Sound-insulated. 5. Insulation. 6. Non-corrosion. 7. Non-toxic. 8. Tough, rigid with the high impact strength. 9. Stable color retention. |

4.Production process:

The screw feeder takes the material from the 5m3 silo(~ 3 tons) → The Extruder Feeding Hopper → The extruder → Material Plasticizing → T-die → Forming Platform →Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Stacking Machine

5.Finished Products:

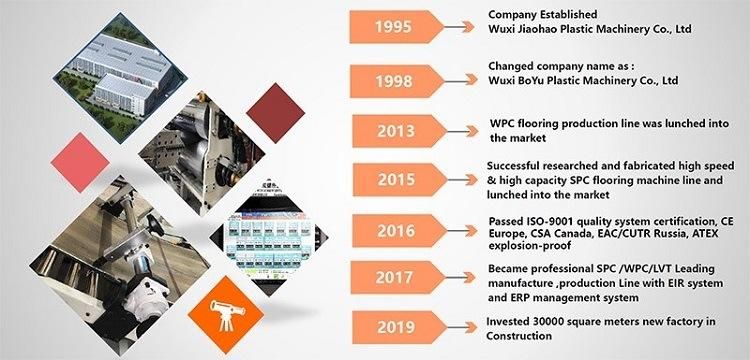

6. Boyu Company Development:

7.Our Service:

1. Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2. After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3. Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

8. Shipping:

9. Certificate: