Hr1-25 Diesel Engine Interlocking Brick Machine Without Electricity

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Semiautomatic

- Type:Hydroforming

- Brick Raw Material:Clay, Crushed Stone, Coal Cangue

- Dimension(L*W*H):810*400*1200mm

Base Info

- Model NO.:HR1-25

- Progress:Carburizing Technology and Heat Treatment Process

- Motor:Siemens

- Mold:Changeable, Steel Casting Molds

- Voltage:380V

- Power:2.2kw

- Colour:According to Your Demand

- Price:Cheap

- After-Sales Service:Engineers Available to Service Machinery Overseas

- Transport Package:Iron Box or Wood Box with Angle Iron Frame

- Specification:CE, BV , SGS , ISO9001: 2008

- Trademark:HENRY

- Origin:Shandonglinyi

- HS Code:8474802000

- Production Capacity:180 PCS of 230X220X115mm Per Hour

Description

Capacity Table

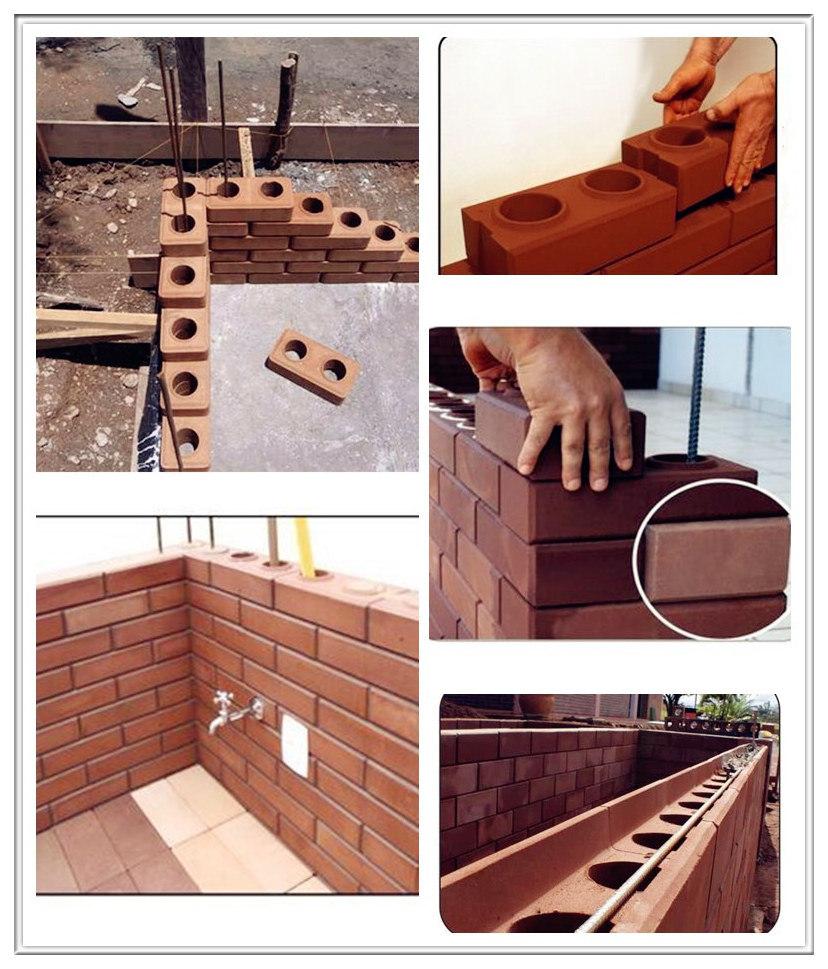

Brick samples showing

Company profile

Henry Industrial Co., Ltd has been committed to the designing, manufacturing and selling construction machinery. We have the domestic advanced equipments, super professional skills, and 20 year production experience.

The company stands in the development of block machine and has extended the related machinery production and sale, mainly in construction machinery, road building machinery, heavy machinery and equipment. At present, main products have reached block machine, brick machine, AAC light brick, road brick machine, paving machine, curb-stone machine, electric pole equipment, pipe making machine, crusher, mixer, generator, loaders, excavators, piling driving machine, cutting machine, plastic mould and so on.

The company has been put the new technology, new products in the first place, has applied for 23 patents, the patent technology guarantee equipment to be rationality, stability, reliability, customers have been widely praise and acclaim on it .Company products are exported to Europe and the United States, Africa, the Middle East and America more than 100 countries and regions, now has 3 offices in foreign countries, which provide good customer service after sale for foreign customers.

FAQ

A: Our blocks are composed of soil and mixed with 8-10% cement

A: laterite soil or "Murrum" is preferred . Generally you can use soil with a 15-35% clay and silt content.

A: We recommend that blocks are cured under black plastic for a minimum of 7 days. Allow the blocks to dry for a further 7 days before building. Blocks will achieve maximum strength after 28 days

A: We recommend a minimum of 8% cement which once properly cured should yield a Min 7MPa block.

A: We recommend fresh, high quality cement with a strength class of 42,5N or higher be used.

CONTACT INFORMATION

Mary Tang

Tell : +86 15762995618 / 0086 539 8110897