Africa Concrete Block Brick Making Machine, Interlocking Paving Brick Molding Machine

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Warranty:3 Years After Manufacturing Date

- Certification:CE, ISO

Base Info

- Model NO.:QTJ4-40

- Customized:Customized

- Automatic Grade:Semiautomatic

- Type:Vibration Molding

- Transport Package:Wooden Carton

- Specification:1580*1100*2100mm

- Trademark:Henry interlocking brick making machine

- Origin:China

- HS Code:8474802000

- Production Capacity:30 Sets Per Month

- Package size per unit product:1580.00cm * 1100.00cm * 2100.00cm

- Gross weight per unit product:1500.000kg

Description

Pallet size

850x550x25mm (bamboo)

850x550x20mm (bamboo)

Vibration frequency

2800 r.pm

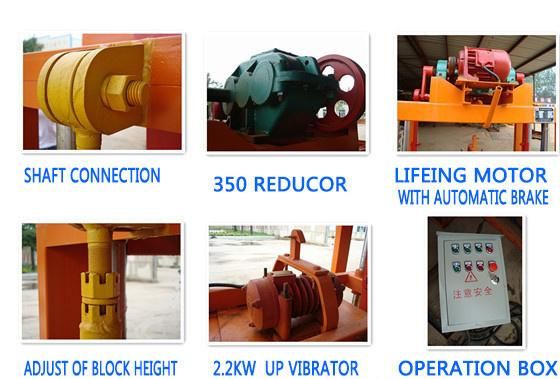

Upper vibrator

2.2KW

Nether vibrator

4.4kw

Electricity

380V/220V (adjustable)

Total weight

1500 KGS

Machine description

QTJ4-40 Block making machine meets the state standards of GBT

85331998. Excellent inperformance,high in efficiency and lower in energy consumption.

The QTJ4-40 Block making machines can produce all kinds of hollow block.solid brick,whichare widely used in the construction of municipal works, buildings,garden sand roads an its productivity is high.

Shape of bricks

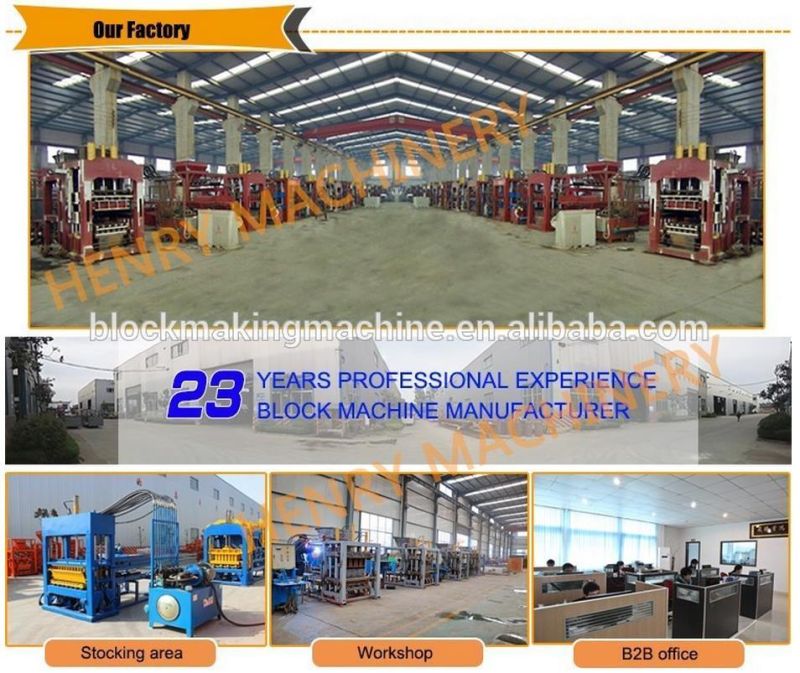

Company view

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

Guarantee

(1)We can supply one year guarantee period for our brick making machines,if the client have the question ,they could call our service department number any time , we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client

place to help.

please Contact Us and send us a inquiry