Non Combustible MGO Wall Board Production Machine

OYADE (Shandong) Machinery Equipment Co., Ltd.- After-sales Service:Video Technical Support, Site Support

- Warranty:1 Year

- Product Type:MGO Board Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Single-Screw

Base Info

- Condition:New

- Customized:Customized

- Application:MGO Board Production

- Product Name:MGO Board Production Line

- Automation:Full Automatic

- Workshop Size:≥7000sqm ,High≥7m

- Control System:PLC Simens

- Famous Brand Used:Electric Control

- Finish Product Size:1220*2440,3000mm

- Finish Product Type:Standard Board ,Sanding Board

- Raw Material:MGO Powder,Mgso4,Perlite,Bamboo,Fiber Glass Mesh

- Shaft Mixer:Double

- Finish Product Thickness:3-25mm

- Finish Product Application:Interior,Exterior Wall, Floor, Ceiling, etc

- Power Supply:Electric

- Transport Package:Strong Wood Pallets

- Specification:1220x2440mm, 1220*3050mm

- Trademark:Yurui

- Origin:Shandong, China

- Production Capacity:20 Sets Per Year

Description

Basic Info.

Condition New Customized Customized Application MGO Board Production Product Name MGO Board Production Line Automation Full Automatic Workshop Size ≥7000sqm ,High≥7m Control System PLC Simens Famous Brand Used Electric Control Finish Product Size 1220*2440/3000mm Finish Product Type Standard Board /Sanding Board Raw Material MGO Powder/Mgso4/Perlite/Bamboo/Fiber Glass Mesh Shaft Mixer Double Finish Product Thickness 3-25mm Finish Product Application Interior/Exterior Wall, Floor, Ceiling, etc Power Supply Electric Transport Package Strong Wood Pallets Specification 1220x2440mm, 1220*3050mm Trademark Yurui Origin Shandong, China Production Capacity 20 Sets Per YearProduct Description

Machine Description

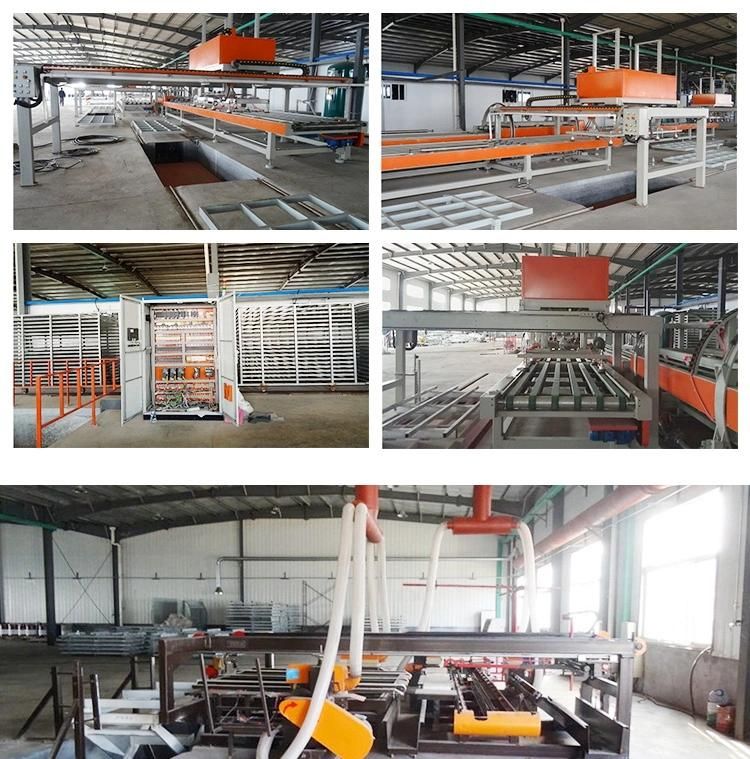

"The whole machine uses both the shaft and chain hybrid transmission,stainless steel beam bridge to prevent the stripping and dragging, and improve the product quality and finished product rate.improve the synchronous running stability of the mold, protect the mold, and is very easy to clean.The structure of the machine is simple and easy to maintain. Extremely low maintenance rate of the consumable parts, and the consumable parts are universal and easy to replace, no specific purchase required.

The whole line is made of 304 stainless steel drum the diameter is 240mm, which is suitable for chloride magnesium products, sulfate magnesium products, cement products, non-corrosive and durable, easy to clean.A set of solutions can produce a variety of plates, whether it is the MgO board or the cement board, to meet the needs of different customers and occupy more market shares."

Machine Parts

It used PCL automatic control system, gang control for each part. it is automatically, less labor and high efficiency. And we design automatic feeding system for measurement and rate precisely. Also, most parts of this system has professional dedusting system, so there is even no dust during the production, the workshop environment is much more better.

The whole line used PCL automatic control system, gang control for each part, and has the function of re-seperation of the plate and mold, so it has no adhesion between them. it is automatically, less labor and high efficiency.

The whole line adopts PLC automatic control system, the system has the functions of automatic board-loading, automatic board-arranging, automatic cutting, automatic stacking and automatic edge-feeding. each link realizes linkage control, high automation and less Labor.

Using two or more sanding machines to connect and automatically turn over the board, the board can meet the requirements of the customers, and meet the different sanding requirements of the customers.

Control system uses Siemens PLC, touch screen control and servo motor system. All the whole system has ethernet interface, it can connect with frequency converter, control the motor start and stop, also control the speed.

Hot Air, electric heating and heat conducting oil are used in maintenance room for customers to choose. Adopt PLC intelligent system, can realize automatic heating, automatic mixing heat, automatic regulating and automatic maintenance.

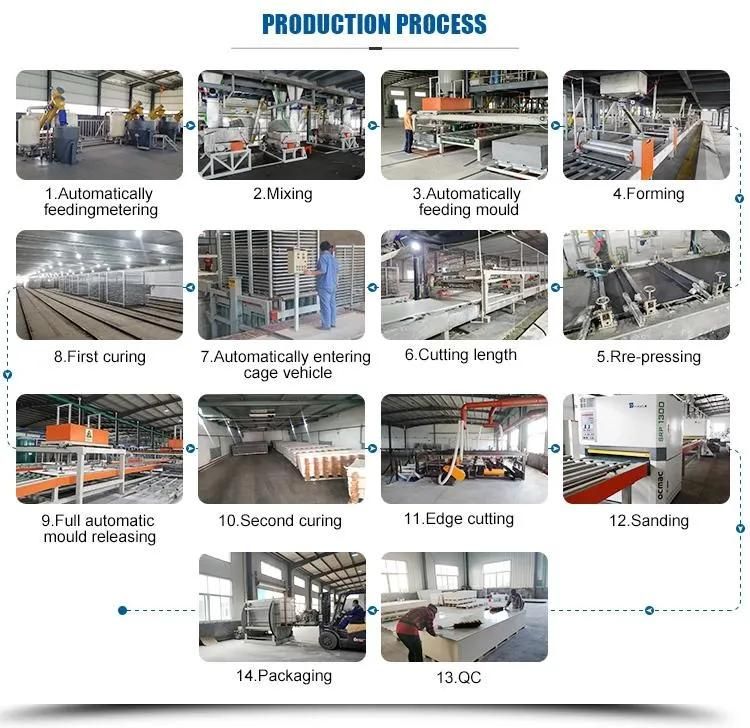

Production Process

We always insist on quality is the most important factor

1)From the beginning production line and layout designing, after order confirmed, we will provide foundation drawing for you to prepare civil works.

2)When the equipment arrived, we will dispatch engineers to install and commissioning the production line for you. At the same time we will train the workers and adjust suitable production formula for you to guarantee you produce qualified panels.

3)When the project finished, our service will still continue, we will guide you how to maintain the equipment, if you need to buy raw material, like additives,also we can help you contact with our long-term cooperation factory with reasonable price.

4)What's more important, If we develop new technology or have updated product formula, also we will inform you to help you update.

5)If necessary, we can arrange one engineer stay in your factory to guide production and management. And you only need to pay for his salary. Our company's philosophy is to provide customers high-end production line with one-stop service to guarantee you a 100% sucessful project.

About Us

We are a professional team in board manufacturing technique, material and equipment development, and manufacturing, we can help you from investment planning to production, from installation, training to supply reasonable project, stable machinery equipment, and after-sale service, it lowers your investment risks.

We always regard "customers are God, service is never stopped" as our company's business objectives, we supply professional technique guidance and after-sale service to get more business opportunities and customer's trust.

We are building material group company with 8 branches specialized in different building material and machinery manufacturing with 30 years history. our company occupies the finest MgO board production, formula, and the highest configuration machinery equipment in china.

- Deeply study MgO board and production machinery for 20+years, and own top technique.

- Engineers and workers own tens of years of experience and professional technology.

- Equipped with a high automatic production line, ensure the standard and consistent processing.

- Regularly trained to improve standard operation and security.

- Strict QC system and implement

- Professional and considerate after-sales service

- Enough capacity to ensure the delivery time

Our company's philosophy is to provide customers high-end production line with one-stop service to guarantee you a 100% successful project.

FAQ

Q: How long is the warranty of your equipment?

A: 1year

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Q: How will you provide installation&commissioning

A: Will provide 2~8 persons(adjustable according to the degree of automatic )for installation. Engineers team will go with your project.

Q:How long time for the installation and commissioning

A: depend on configuration normally only need 15-25days. Including workers training.

Warmly welcome you contact me for your questions.