Qt4-15 Full Automatic Cement Brick Making Machine, Including Hollow Bricks

Shandong Xinming International Trade Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

- Model No.:Qt4-20

- Size of Pallet:850*550*250mm

Base Info

- Model NO.:QT4-15

- Number of Worker:5-7workers

- Motor Brand:German Siemens

- PLC Brand:Janan Mitsubishi

- Capacity:4000-7000PCS Per Day

- Guarantee:18 Months

- Voltage:380V

- Molding Cycle:20 Seconds

- Vibration Force:80kn

- Machine Weight:4t

- Transport Package:Wooden Package

- Specification:3700*2100*2300mm

- Trademark:Xinming

- Origin:China

- HS Code:8474802000

- Production Capacity:6240-7680PCS Per Day

Description

Main specification and technical parametersOverall size 1500(L)×1500(W)×1300(H)mm(assembled) 1500(L)×1500(W)×800(H)mm(seperated) Shaping cycle 5 mins Volume 350L (25Kgs Cement) Electricity 380V/220V/ (adjustable) Total weight 330KGS

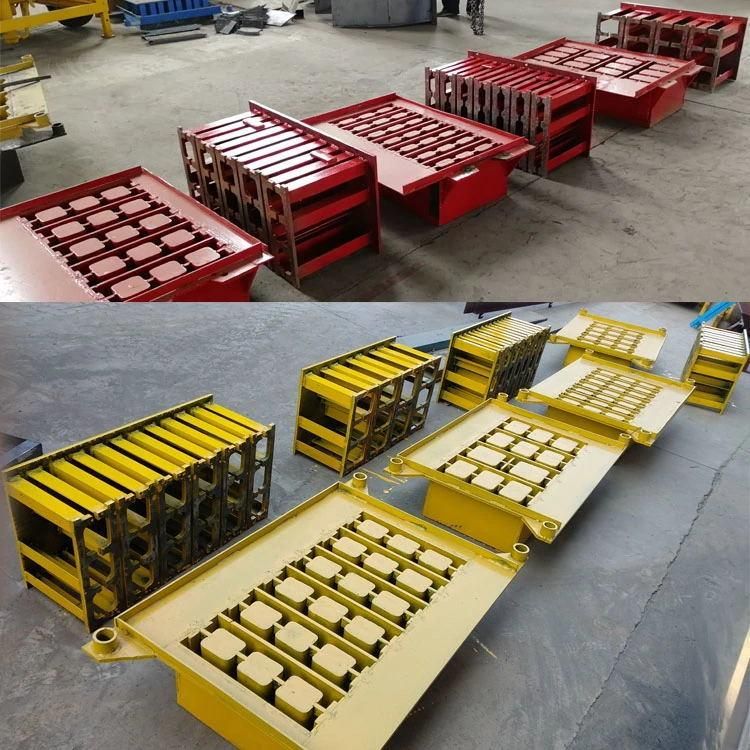

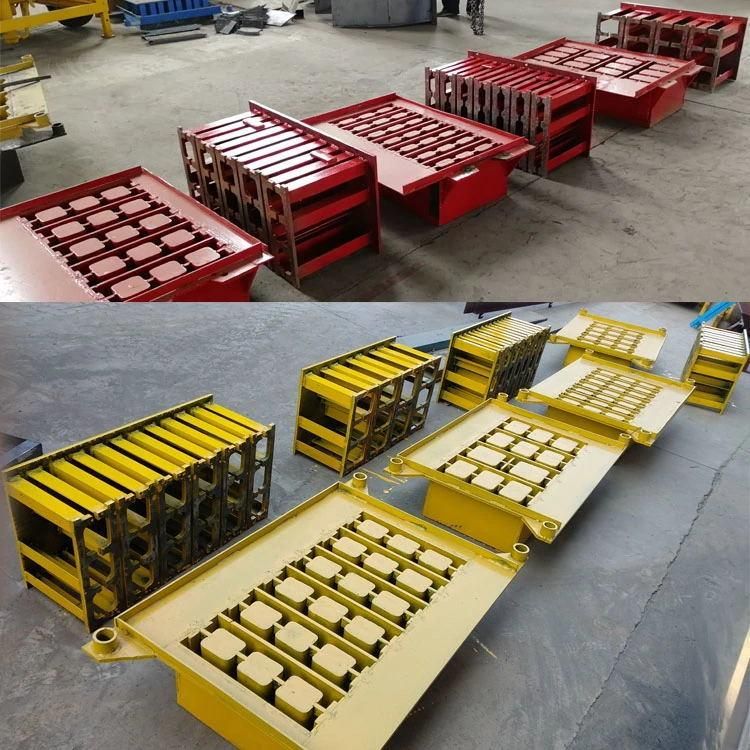

Capacity for sizes of blocks and pavers produced by QT4-20 automatic concrete hollow block making machine, cement brick machine

Qt4-20 automatic cement brick making machine, concrete hollow paver block making machine in construction machinery.

Our Service

we have go big after sale service team , they are all the experience technician ,

over 20 workers have the passport ,they all have the oversea experience.

So we not only have good service in the pre service , we also think highly of the after sale service.

(1)We can supply one year guarantee period for our brick making machines,if the client have the question ,they could call our service department number any time , we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client

place to help.

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

Capacity for sizes of blocks and pavers produced by QT4-20 automatic concrete hollow block making machine, cement brick machine

Qt4-20 automatic cement brick making machine, concrete hollow paver block making machine in construction machinery.

Our Service

we have go big after sale service team , they are all the experience technician ,

over 20 workers have the passport ,they all have the oversea experience.

So we not only have good service in the pre service , we also think highly of the after sale service.

(1)We can supply one year guarantee period for our brick making machines,if the client have the question ,they could call our service department number any time , we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client

place to help.

Pre-sale:

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other