Thermal Break Aluminum Profile Assembly Knurling and Inserting Machine

Shandong Truetec Machinery Co., Ltd.- Condition:New

- Certification:CE

- Automatic Grade:Automatic

- CNC or Not:not CNC

- Voltage:380V

- Machine Function:Knurling and Inserting Machine

Base Info

- Model NO.:CLKC-01

- Function:Thermo Break Aluminum Profiles Machine

- Usage:Aluminum Window Making Machine

- Motor Power:2*1.5kw

- Power Supply:380V,50Hz

- Profile Size:220*250mm

- Diameter of Roller Wheel:90mm

- Work Speed:6 ~70m,Min(Stepless Speed Regulating)

- Support Wheel High and Low:0-20mm

- Overall Dimension:1000*1100*1550mm

- Weight:About 800kg

- Origin of Factory:Jinan Machine

- Color:Optional

- Name:Thermo Break Aluminum Profiles Machine

- Material:Aluminum Profile

- Transport Package:Wooden Box

- Specification:Thermo Break Aluminum Profiles Machine

- Trademark:TRUEPRO

- Origin:China

- HS Code:8461500090

- Production Capacity:500sets,Year

Description

Basic Info.

Model NO. CLKC-01 Function Thermo Break Aluminum Profiles Machine Usage Aluminum Window Making Machine Motor Power 2*1.5kw Power Supply 380V/50Hz Profile Size 220*250mm Diameter of Roller Wheel 90mm Work Speed 6 ~70m/Min(Stepless Speed Regulating) Support Wheel High and Low 0-20mm Overall Dimension 1000*1100*1550mm Weight About 800kg Origin of Factory Jinan Machine Color Optional Name Thermo Break Aluminum Profiles Machine Material Aluminum Profile Transport Package Wooden Box Specification Thermo Break Aluminum Profiles Machine Trademark TRUEPRO Origin China HS Code 8461500090 Production Capacity 500sets/YearProduct Description

Thermal Break Aluminum Profile Assembly Knurling and Inserting Machine

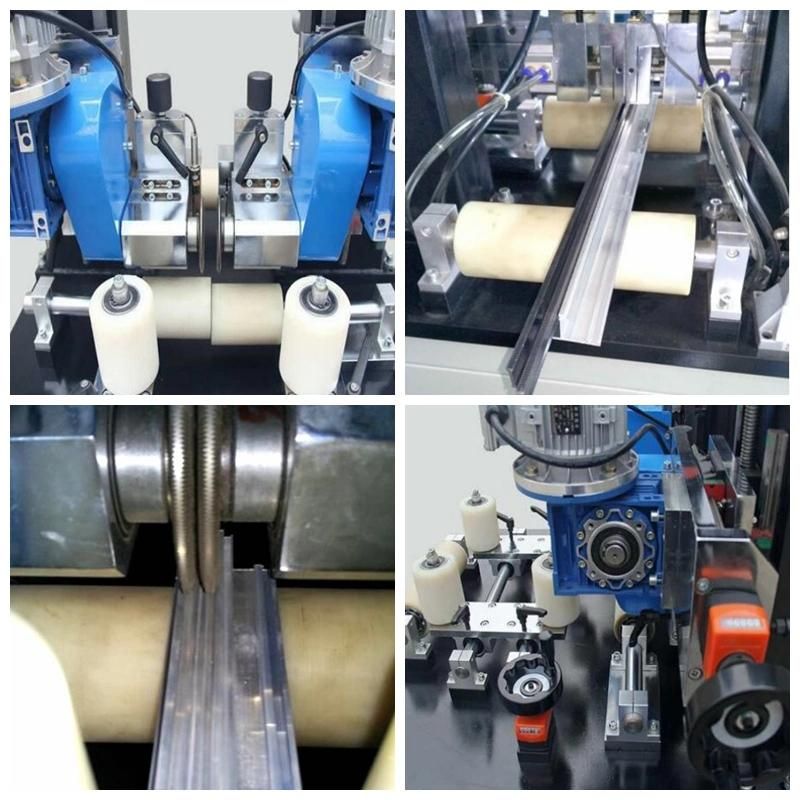

Equipment Features:

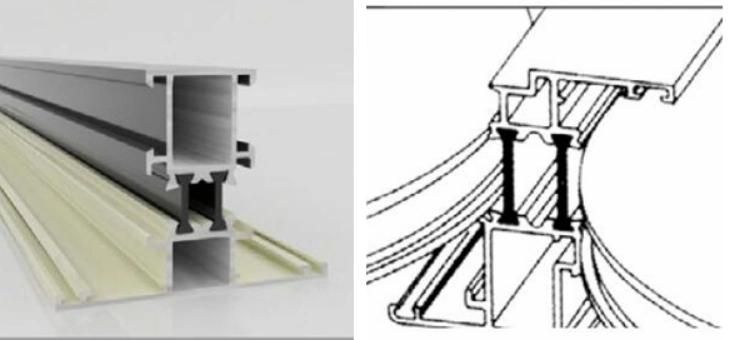

1, Special equipment manufactured for thermal break aluminum profile.

2, It is used to knurl on the notch of thermal break aluminum profile to improve horizontal shear force of profile.

3, It is the key machine to increase shear strength, knurling slot of extrusion profile through rotating knife at a high

speed.

4, Stepless speed regulation is available by using frequency converter.

5, Electric controlled lifting of knurling knife and more stable automatically changing of different profile is available.

6, It can work with laminating frame and clamping device which means the machine poccesses the function of

knurling, strip feeding and laminating film sticking.

7, The machine can inster nylon or PVC strip into profile at the same time of knurling.

Equipment Parameter:

Model | GLKC-01 |

Input power | 2*1.5Kw |

Power supply | 380V/50Hz |

Profile size | 220×250mm |

Feeding speed | 0-70m/min (stepless adjusting) |

| Knurling cutter diameter | 90mm |

| The adjusting range of the hobbing cutter | (Vertical) 180mm (Level) 6 ~180mm |

| Support wheen high and low | 0 ~20mm |

Overall dimension (L*W*H) | 1000 ×1100 ×1550mm |

Weight | 800kg |

Jinan Truepro is a manufacturer of window machine, insulating glass processing machine and curtain wall machine with

Jinan Truepro is a manufacturer of window machine, insulating glass processing machine and curtain wall machine withwell-equipped testing equipment and strong technical force. With a wide range, good quality, reasonable prices and stylish

designs, our products are extensively used in building trade and other industries. Hope we can cooperate with you.

We believe that "IT'S THE BEST THAT FITS MOST."

Every machine could be customized to meet your special requirement.

1. When can we arrange shippment?

We usually arrange shippment within 15 days after getting deopsit,

but customized machines should be more than 25 days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation

training. All of our engineers have passport.

4. If I make Aluminum window and door, how many basic machines do i need?

1)double head cutting saw

2)Lock hole copy milling machine

3)End milling machine

4)Automatic Corner connector automatic cutting saw

5)Single head Corner combining machine