Xm2-25 Semi-Automatic Clay Block Machine Lego and Interlocking Brick Making Machine

Shandong Xinming International Trade Co., Ltd.- Customized:Customized

- Automatic Grade:Semiautomatic

Base Info

- Model NO.:XM2-25

- Type:Hydroforming

- Mold Period:25s

- Color:Customized

- Processing:Brick Moulding Machine

- Package:Xm2-25 Brick Making Machine Is Nude in Container

- Work Way:Hydraulic System

- Vibration Force:30kn

- Labor:2~3workers

- Cooling Way:Water Cooling

- Mixer Model:Jq350 Concrete Mixer

- Model No.:Xm2-25 Clay Brick Machine

- Rated Pressure:21MPa

- Transport Package:Nude in Container, LCL

- Specification:1050*735*1200m

- Trademark:Xinming

- Origin:China

- HS Code:8474802000

- Production Capacity:500PCS,Month

- Package size per unit product:120.00cm * 80.00cm * 140.00cm

- Gross weight per unit product:330.000kg

Description

Basic Info.

Model NO. XM2-25 Type Hydroforming Mold Period 25s Color Customized Processing Brick Moulding Machine Package Xm2-25 Brick Making Machine Is Nude in Container Work Way Hydraulic System Vibration Force 30kn Labor 2~3workers Cooling Way Water Cooling Mixer Model Jq350 Concrete Mixer Model No. Xm2-25 Clay Brick Machine Rated Pressure 21MPa Transport Package Nude in Container/ LCL Specification 1050*735*1200m Trademark Xinming Origin China HS Code 8474802000 Production Capacity 500PCS/MonthPackaging & Delivery

Package size per unit product 120.00cm * 80.00cm * 140.00cm Gross weight per unit product 330.000kgProduct Description

XM2-25 Semi-automatic Clay Block Machine Lego And Interlocking brick Making Machine

The Advantages of XM2-25

1.High Strength: Hydraulic Press, High Strength of Interlocking Brick and pavers

2: Large Capacity per day:2 Bricks in one time and 2500-3000 bricks in 8 hours

3: Adopt advanced technology:Hydraulic System Operation

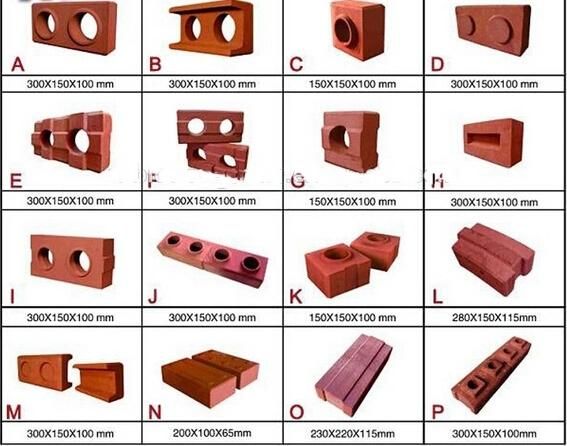

4: Can be changable brick moulds:Producing Designs of interlocking bricks, hydraform block and pavers by changing molds

5: Suitable for small-scale Block Factory or personal use in house

Some Designs of Clay Interlocking Brick Making Machine about XM2-25

Some Details about XM2-25

Basic Information of Our Company

Shandong Xinming International Trade Co., Ltd is a big and famous Construction Company in China. We mainly manufacture the concrete brick making machine and clay interlocking block machine for over 19 years. The block making machines we made have a high quality and get Certified ISO 9001:2009 and CE Standard of Eurotech Germany.

Our company guarantee the rationality, stability and reliability of the products to the greatest extent. What's more, our machines have been widely and highly praised by the customers who come from Europe and the United Stated, South Africa, the Middle East and more than 80 countries and regions.

Our Service

we run a big after-sale service team, they own much the experience about the technology of machines . They also have the overseas experience. Therefore we have good service in the pre-service, we also provide a perfect about after-sale.

Pre-sale

(1) Professional suggestions (including raw material matching, machine selection, plan

the condition of building factory, feasibility analysis for brick machine production line);

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick);

(3) 24 hours on-line service;

(4) Welcome to visit our factory and production line at any time. If you need, we would like to make invitation letter for you;

(5) Introduce the company file, product categories and production process.

Sale

(1) Update the production scheduling in time;

(2) Product acceptance;

(3) Shipping on time.

After-sale

(1) If needed, our engineer will guide to carry out the plant at the clients side;

(2) Set up, fix, and operate patiently for you;

(3) Offer training to the operator until they are satisfied at clients side;

(4) Skill support the whole using life;

(5) Recall clients regularly, get feedback in time ,keep well communication with each other.

Please Contact with Me