Galvanized Roof Sheet Making Machine

Botou Golden Integrity Roll Forming Machinery Co., Ltd.- Certification:ISO9001: 2000, Ce

- Condition:New

- Customized:Customized

- Usage:Roof, Wall

- Use:Roof

- Suitable Material:PPGI, Aluminum

Base Info

- Model NO.:24-200-1000,28-200-1000

- Thickness:0.9-1.5mm

- Power:5.5+4kw

- Voltage:380V50Hz

- Transport Package:According to Customers′ Request

- Specification:Jcx

- Trademark:JCX

- Origin:China Hebei

- HS Code:84552210

- Production Capacity:40sets Per Month

Description

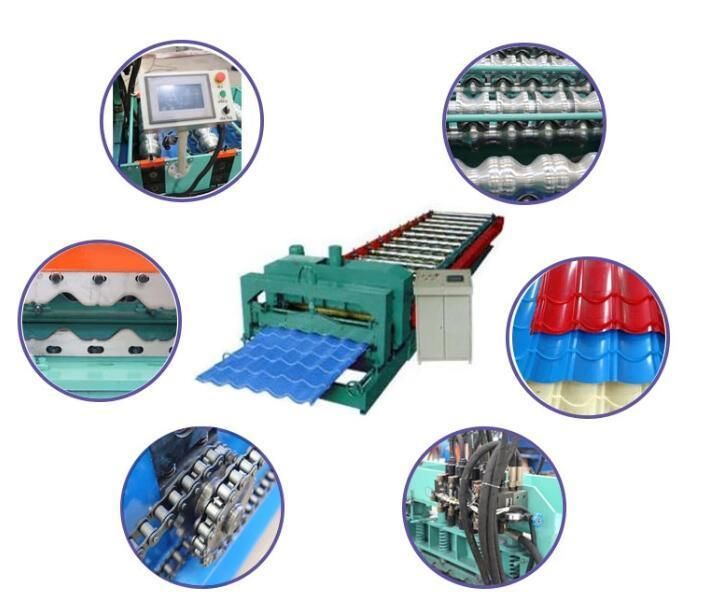

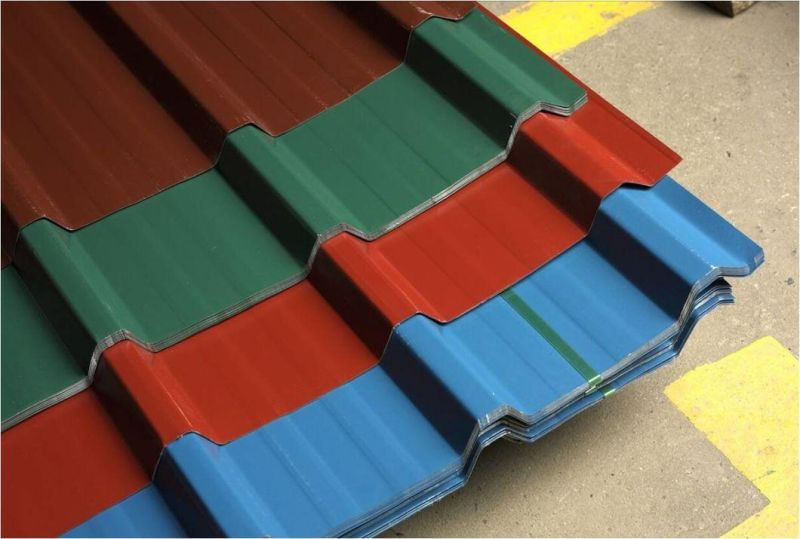

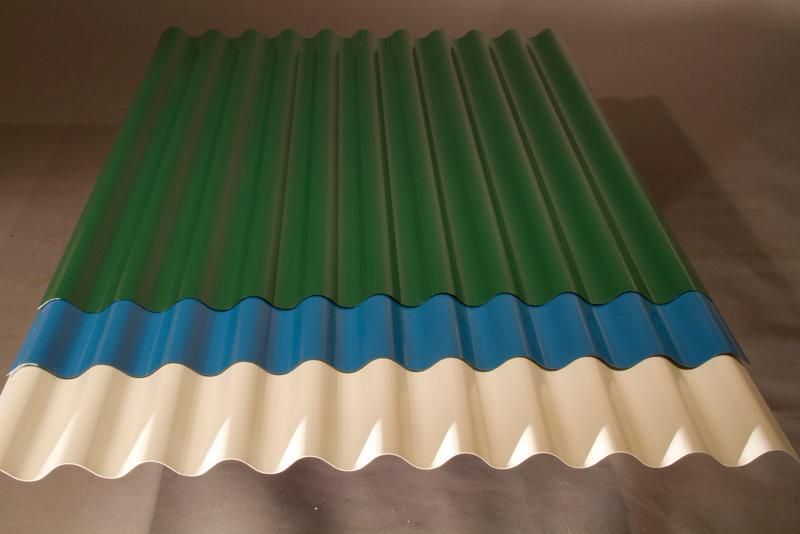

1.Photoes Of roll forming Machine

Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

More Details of our machine

Colored Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

2. Technical Parameters:

Metal Roofing Panel Roll Forming Machine-Roof Sheet Forming Machine

A. General

Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

Length of the Sheet

You can set the length according to your need.

It is controlled by PLC

which can ensure the accuracy of ±1mm.

Automatically stop and cutting when it comes to the set

length.

B. Components Details

Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

16mm. We use thicker plates to ensure stability

of our products.

Φ70 mm, high grade 45# steel.

Treating process: tempering- finish turning,

high rigidity, hard to deform.

Cutting

Blade Material

Cr12, hardness HRC60-62.

Treating process: heat treatment- plane abrasion-wire

electrode cutting.

c.Component line

Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

NO

Name

Unit

Qty

1

Man-made decoiler

set

1

2

Main machine for roll forming

set

1

3

Control system

set

1

4

Hydraulic system

set

1

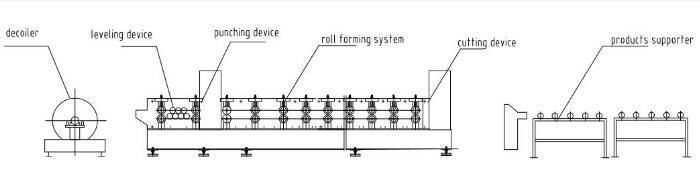

3. Working Flow:

Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

Loading

Packaging & Shipping

Package of Glazed tile IBR roofing sheet Double layer roof tile making roll forming machine

1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded in one 20' container.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

Certifications

Our Services

A. One-Years product warranty.

B. Training and installation available.

C. The technical support for the whole life.