Aluminum Profile End-Milling Machine

Shandong Truetec Machinery Co., Ltd.- Condition:New

- Certification:CE

- Automatic Grade:Automatic

- CNC or Not:not CNC

- Voltage:380V

- Milling Cutter Height:70mm

Base Info

- Model NO.:CLXD-200

- Worktable Dimension:500*350mm

- Dia. of Milling Cutter:110-200mm

- Rotary Speed:2800r,Min

- Power:1.5kw

- Air Pressure:0.5-0.8MPa

- Transport Package:Standard

- Specification:850*740*1280mm

- Trademark:Truetec

- Origin:China

- Production Capacity:15sets,Month

Description

Basic Info.

Model NO. CLXD-200 Worktable Dimension 500*350mm Dia. of Milling Cutter 110-200mm Rotary Speed 2800r/Min Power 1.5kw Air Pressure 0.5-0.8MPa Transport Package Standard Specification 850*740*1280mm Trademark Truetec Origin China Production Capacity 15sets/MonthProduct Description

Aluminum Profile End-milling Machine

Machine feature:

♦ For end milling of transom and door frames in aluminum and PVC profile.

♦ Automatic feeding. Standard pneumatic cylinder. Optional hydro-pneumatic cylinder.

♦ Two vertical clamping ensure stable positioning.

♦ Cutter easily changing for various profile.

♦ Various angle mullion milling for arch window or other special shape window.

♦ Hand wheel for different height adjustment.

♦ Safety covers on the milling cutter.

Parameter:

| Model | CLXD-200 |

| Input Voltage | 380V 50Hz or customer specification. |

| Input Power | 1.5 (kW) |

| Main-shaft Revolution | 2800(r/min) |

| Air Pressure | 0.6~0.8(MPa) |

| Diameter of main shaft | 32mm |

| Diameter of milling cutter | 110-200mm |

| Worktable journey | 0-320mm |

| Worktable dimension | 500*350mm |

| Motor adjustable journey | 0-80mm |

| Turning angle of location board | 0-55° |

| Ma.processing tenoning size | 70*45*200mm |

| Dimension | 850*740*1280mm |

| Weight | 300kg |

Machine details:

Machine processing

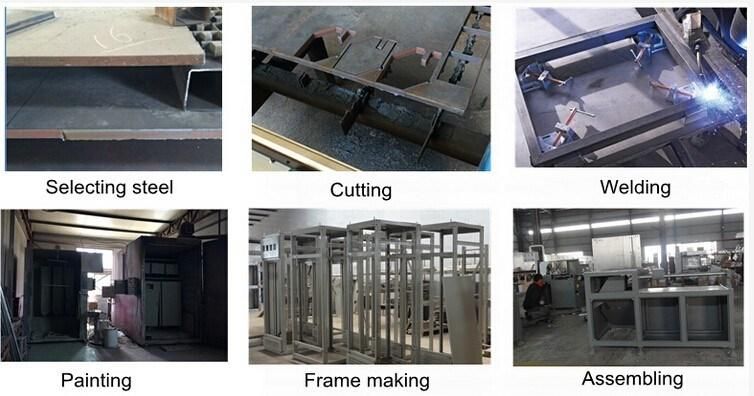

We work with everything from raw material to final machine, could guarantee machine quality from each step. select each part carefully, we are strive to quality first when machine production and test each machine before delivery.

We will provide the best machine for you.

Packing & Delivery

Certifications

ISO9001/2000 International Quality Certification

CE Certification

Most advanced technology and high level configuration

Personalized service and perfect after-sale service

Company Information

Our Service

Pre-sale service

Free contact for the most suitable machineFree professional design for each customer especially.

After sale service

24 hours technical support by phone, email or skype1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

PaymentP

L/C, 30% deposit by T/T,70% spare payment L/C.

T/T, 30% deposit by T/T,70% spare payment before shipment.

Western Union or Paypal.

FAQ

1. When can we arrange shippment?

We usually arrange shippment within 15 days after getting deopsit,

but customized machines should be more than 25 days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

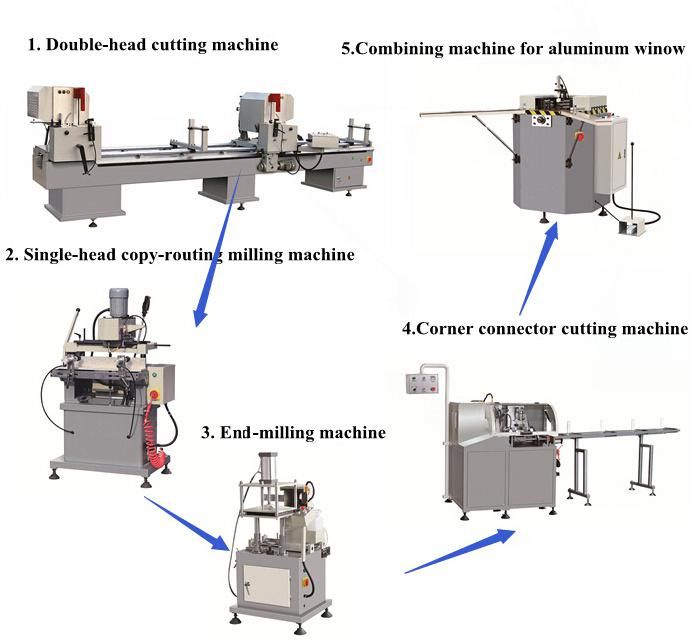

4. If I make Aluminum window and door, how many basic machines do i need?

1).double head cutting saw

2).Lock hole copy milling machine

3).End milling machine

4).Automatic Corner connector automatic cutting saw

5).Single head Corner combining machine