High Speed Automatic W Beam Guard Rail Roll Forming Machine for Sale

Cangzhou Nexus Machinery Co., Ltd.- After-sales Service:Provide Overseas Service

- Warranty:1 Year

- Certification:CE, GS, ISO9001

- Customized:Customized

- Condition:New

- Control Type:CNC

Base Info

- Model NO.:NM335

- Automatic Grade:Automatic

- Product Name:Automatic W Beam Guard Rail Roll Forming Machine

- Motor Power:50kw

- Material of Punching Mould:Cr12MOV

- Hydraulic Power:7.5kw

- Roll Forming Station:16 Groups

- Raw Material:Black Steel & Galvanized Steel

- Thickness of Raw Material:2.0-4.0mm

- Weight of Machine:About 25ton

- Electricity:PLC Detal, Made in Taiwan, 380V 50Hz, 3 Phases

- Operation Language:English and Chinese

- Transport Package:Steel Wires Fixed and 40gp Container Load

- Specification:9000mm*1800mm*1500mm(L*W*H)

- Trademark:NEXUS MACHINERY

- Origin:Cangzhou, China

- HS Code:8455221000

- Production Capacity:10 Sets Per Month

Description

Basic Info.

Model NO. NM335 Automatic Grade Automatic Product Name Automatic W Beam Guard Rail Roll Forming Machine Motor Power 50kw Material of Punching Mould Cr12MOV Hydraulic Power 7.5kw Roll Forming Station 16 Groups Raw Material Black Steel & Galvanized Steel Thickness of Raw Material 2.0-4.0mm Weight of Machine About 25ton Electricity PLC Detal, Made in Taiwan, 380V 50Hz, 3 Phases Operation Language English and Chinese Transport Package Steel Wires Fixed and 40gp Container Load Specification 9000mm*1800mm*1500mm(L*W*H) Trademark NEXUS MACHINERY Origin Cangzhou, China HS Code 8455221000 Production Capacity 10 Sets Per MonthProduct Description

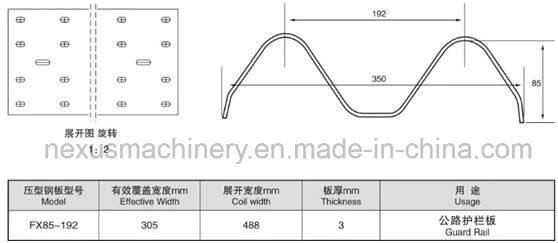

High Speed Automatic W Beam Guard Rail Roll Forming Machine For SaleProfile drawings:

The thickness of Material: 2.0-4.0 mm

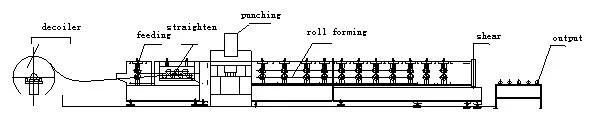

Working flow:Uncoiler-Feeding-Leveling-- hydraulic punching-Roll forming-Hydraulic cutting-output table

Main Specification

Manual decoiler

- Capacity: 3 ton

- Loading width: MAX 600mm

- Valid expanding range for coil inner diameter: 480-520mm

- Main motor power: 50kw

- Separate motor reducer: 750type

- Punching: Hydraulic pre-punching before forming

- Punching mould:Cr12mov

- Hydraulic power: 7.5KW

- Roller material: Gcr15 bearing steel and quench treatment hardness 58-62, chrome coated0.05mm

- Leveling rollers: 7rollers(three upper and four lower)

- Roll forming station: 16 groups

- Diameter of main shaft: 100mm

- Drive: independent gearbox with universal joint

- Raw material: Black steel & galvanized steel

- Thickness of Raw material: 2.0-4.0mm

- Width of Raw material: 482mm

- Working speed: 10m--15m/min(Exclude cutting time)

- Cutting: Hydraulic cutting after forming, Auto cutting when reach the set length.

- Cutting blade: Cr12mov

- Cutting tolerance: +/- 1.5mm

- Hydraulic pressure: 30Mpa

- Weight of machine: about 25ton

- Size of machine: About 9000×2150×1500mm L x W x H

- Color of machine: yellow and blue

- Coder: Omron

- Control: PLC Delta, made in Taiwan, 380V 50HZ, 3 phases (Also can design)

- Computer operating panel: touching screen

- Photos of Roll Forming Machine for Reference: