Hr1-10 Best-Selling Automatic Concrete Block Machine, Soil Interlocking Brick Machine, Hydraulic Pressure Method Clay Brick Making Machine

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- After-sales Service:24-Hours

- Warranty:3 Years

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Semiautomatic

- Type:Hydroforming

Base Info

- Model NO.:HR1-10

- Colour:According to Your Demand

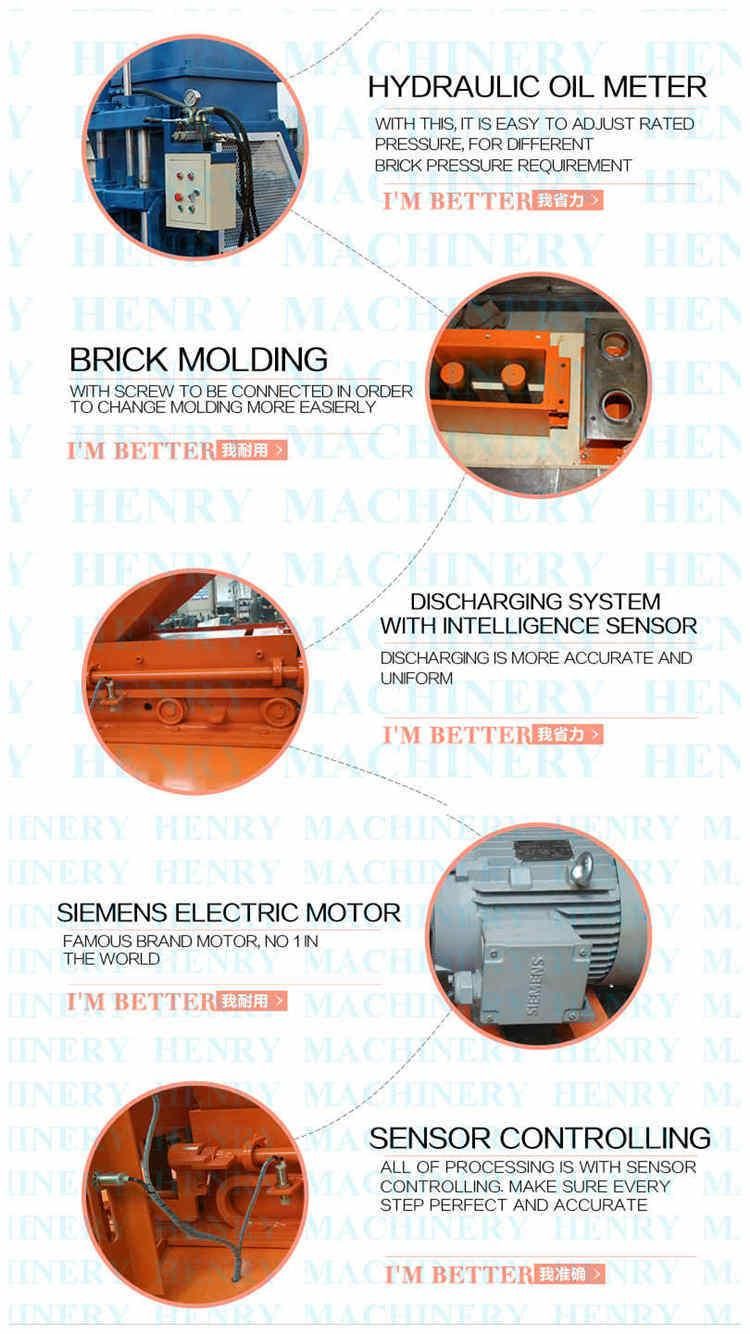

- Motors:Siemens

- Voltage:380V

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Molding Cycle:6-10s

- Weight:1000kg

- Cooling Way:Water Cooling

- Rated Pressure:16-25MPa

- Overall Size:1000X1000X1800mm

- Transport Package:Iron Box or Wood Box with Angle Rion Frame

- Specification:CE SGS ISO

- Trademark:HENRY

- Origin:China(Mainland) Shandong Linyi

- HS Code:8474802000

- Production Capacity:200PCS,Year

Description

Basic Info.

Model NO. HR1-10 Colour According to Your Demand Motors Siemens Voltage 380V After-Sales Service Provided Engineers Available to Service Machinery Overseas Molding Cycle 6-10s Weight 1000kg Cooling Way Water Cooling Rated Pressure 16-25MPa Overall Size 1000X1000X1800mm Transport Package Iron Box or Wood Box with Angle Rion Frame Specification CE SGS ISO Trademark HENRY Origin China(Mainland) Shandong Linyi HS Code 8474802000 Production Capacity 200PCS/YearProduct Description

The whole show of HR1-10 soil lego interlocking block machine

Advantages of HR1-10 block machine (for sell)

1. fully automatic production line ,soil interlocking brick machine

2. fastest shaping shift, 6 second

3. self-picking system, saving labor

4. 15 Mpa pressure

HR1-10 block machine specification

| rated power | 3 kw or 15 HP diesel engine |

| overall size | 1000x1000x1800mm |

| weight | 1000kg |

| cycle | 10 seconds |

| electricity source | 380v/50HZ (adjustable) |

| Cooling way | Water cooling |

| Switch | Automatic |

| rated pressure | 16mpa |

The form and the size of interlocking brick

Company profile

Our sevice

we have go big after sale service team , they are all the experience

technician , over 20 workers have the passport ,they all have the oversea

experience.

So we not only have good service in the pre service , we also think highly

of the after sale service.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

FAQ:

1. What is the brand? ( Now a lot companies embezzle our brand, pls take

note our logo prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market? (we got good reputation and are the biggest supplier in China)

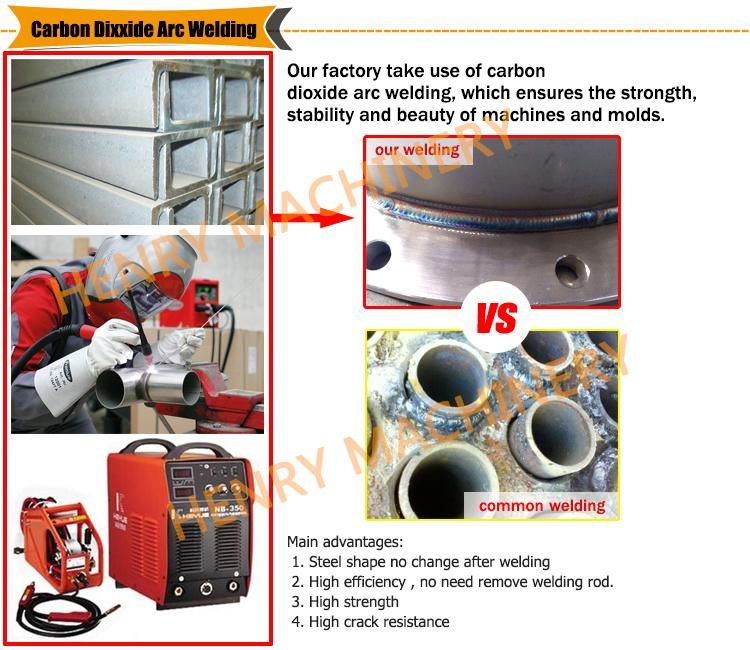

3. What is the materials they used? Maganese steel or A3 steel?

(We use Maganese steel which stronger than A3 steel)

4. What is the lifetime of the mold?

( our mold can use 800,000 - 900,000 times)

5. What is the capacity of this machine?

(2400-3200 pcs/8 hours hollow brick)

6.What is the guarantee period?

( We guarantee for one year)

7.The price cover what equipment?

( pls refer to our quotation list)