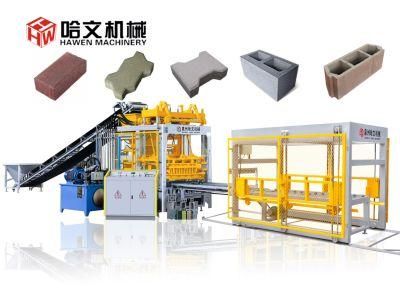

Hot Sales in Africa Automatic Concrete Block and Brick Making Machine

Quanzhou Hawen Machinery Co., Ltd.- Certification:ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- M140 Hollow Block:12PCS Per Drop

- Interlocking Paver:36PCS Per Drop

Base Info

- Model NO.:QT10-15

- Vibration:Motor Vibration

- Raw Material:Crushed Stone Sand and Cement

- After Sales Service:Engineer Available to Abroad

- Warranty:One Year After Installation

- Bevel Paver:36PCS Per Mould

- Plant in South Africa:Newcastle City etc..

- Transport Package:Standard Ocean Packing

- Trademark:HAWEN

- Origin:China

- HS Code:8474809090

- Production Capacity:300 Sets, Year

Description

Basic Info.

Model NO. QT10-15 Vibration Motor Vibration Raw Material Crushed Stone Sand and Cement After Sales Service Engineer Available to Abroad Warranty One Year After Installation Bevel Paver 36PCS Per Mould Plant in South Africa Newcastle City etc.. Transport Package Standard Ocean Packing Trademark HAWEN Origin China HS Code 8474809090 Production Capacity 300 Sets/ YearProduct Description

Hot Sales in Africa Automatic Concrete Block and Brick Making MachineHawen block making machines are for the manufacture of concrete bricks, blocks and paving. The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

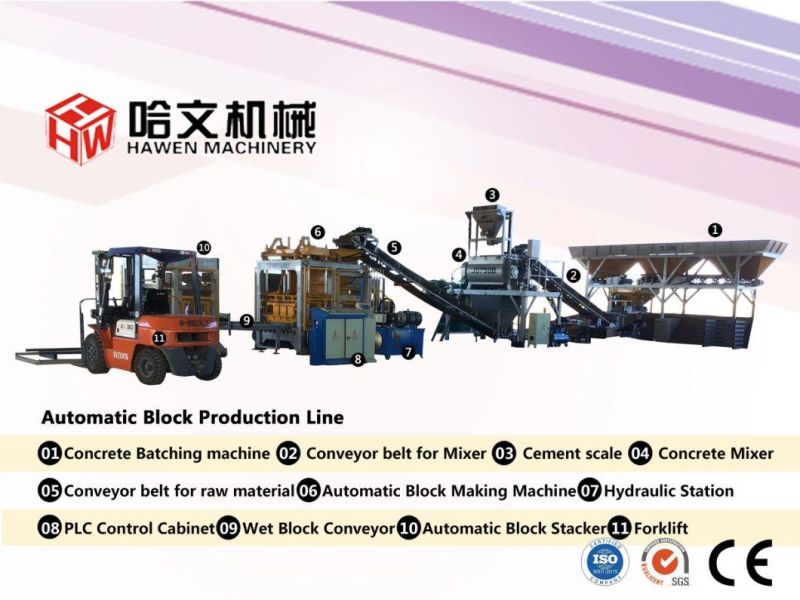

We provide turnkey solution for complete concrete block plants to suit customer requirements!

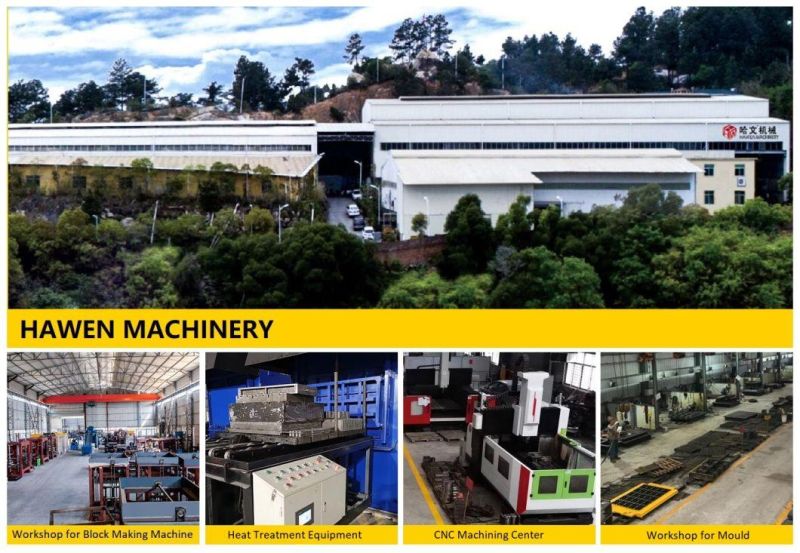

Factory workshop

Brief Introduction

QT10-15 is a hydraulically operated universal block machine ,it is well known for its high performance and excellent flexibility. The intuitive control makes this the ideal machine for the economic production of paving stones, large slabs, kerbs, hollow /solid blocks and special products.

QT10-15 Cement brick making machine is fully automatic with PLC (Programmable Logic Controller) intelligent control.

The control system of brick making machine is equipped with SIEMENS PLC, production program, malfunction diagnosis system and remote control function,easy for operation and maintenance.

Main forming machine equipped with a basic Face-mix device,it can make the double layer paving stone just by changing the mould.

Vibration System

Hang vibration table could bear violent vibration without any damage to crack. And vibration table placed on rubber spring could greatly reduce noise around 10~15 decibel and avoid damage to machine.

The vertical vibration made by eccentric vibration shaft will guarantee the quality and density of concrete products

Strong Frame Structure

The main machine adopts a movable beam,high strength steel structure, four oriented pill an elevating frame which can be adjusted according to the mold height simply and conveniently;The guide column is made of super strength seel, the surface chromium plating has high strength and wear resistance.

Hydraulic system

Hydraulic components adopts famous brand Yuken, we use high-dynamic proportional and directional valves, which automatically adjust the oil flux and pressure as per specific working

Requirements, Adjusting hydraulic pressure and flow controls vibration frequency and range thus change forming cycle time according to different concrete products

Technical specification:

| Pallet size | mm | 1100×950×28 |

| Cycle time | S | 15-23 |

| Rate Pressure | Mpa | 31.5 |

| Vibration force | KN | 105 |

| Power | KW | 48.9 |

| Weight | T | 14.5 |

| Vibration frequency | r/min | 3800-4500 |

| Dimension | mm | 11500×4050×2800 |

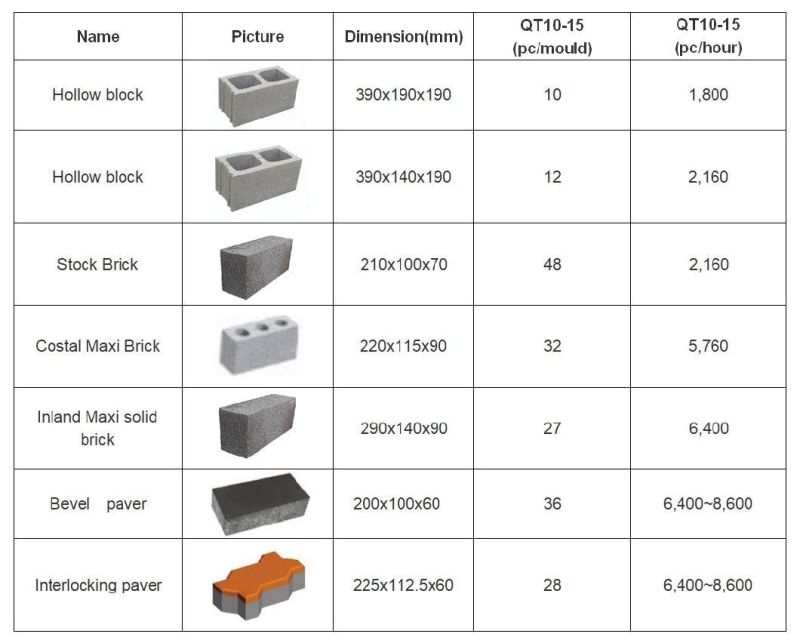

Output of QT10-15 Block machine in South Africa (Pallet size 1100*950mm)

Precision depends on the process. Different processing equipments to ensure high precision for equipments components and moulds.

Application of QT10-15 Block Making Machine at site

M140 Hollow Block,Interlocking paver 200x100x80mm at 36pcs per mould, Stock brick,Inland Maix solid brick made by our QT10-15 block making machine in South Africa.

Container loading in workshp for customers overseas

Different shape and dimension of Cocnrete products can be made by our Block Making Machine.

We participate the exhibitions in different countries overseas,to know more about the local customer requirement for Concrete products and block making equipments.

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order