Double Layer Long Span Corrugated Steel Roofing Roll Forming Machine

Botou Golden Integrity Roll Forming Machinery Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Tile Type:Colored Steel

- Certification:CE, ISO, ISO9001: 2000, CE

- Condition:New

- Customized:Customized

Base Info

- Model NO.:JCX-double DK1

- Usage:Roof, Wall

- Transmission Method:Electric

- Use:Roof

- Suitable Material:PPGI Gi,Gl, Alunimum Alloy

- Thickness of Material:0.2-0.8mm

- Speed:10-15m,Min

- Power:4+4kw

- After Sale Service:Engineer Available

- Transport Package:According to Customers′ Request

- Specification:JCX

- Trademark:JCX

- Origin:China Hebei

- HS Code:84552210

- Production Capacity:40sets Per Month

Description

ItemSpecification

Material Type Plate steel Thickness(mm) 0.2-0.8 Yield strength(mpa) 235-345 MPA Roller material 45#Chrome steel Forming speed(m/min) About 15-20 Output speed(m/min) 8-12m/min Speed adjusting mode AC Frequency Roller drive Decelerating motor + Chain drive Cutting mode Hydraulic cutting Cutter material Cr12 mould steel Length measurement Encoder Control mode Mitsubishi PLC Operating mode Button + Mitsubishi Touch screen Main motor power(kw) 7.5KW Hydraulic power 2.2KW Machine size About 9*1.6*1.4m Machine weight About 8 tons

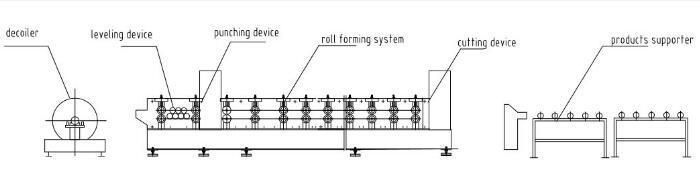

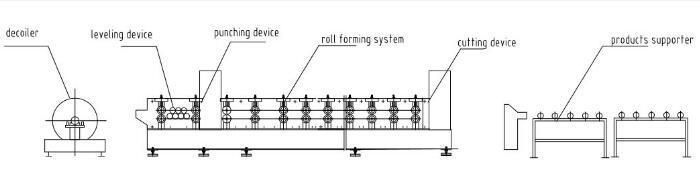

2. Components of machineDecoilerFeeding & guiding device Main roll forming machine 1set Hydraulic cutting system Controlling system Run out table 3m/pcs 2set

3. Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting - Product to Run Out Table

4. Electric elements: Mitsubishi PLC & transducer from Japan.

1. Electric elements: Mitsubishi PLC & transducer from Japan.

2. Anti-rust roller: High grade No. 45 forged steel. Plated with 0.05mm hard chrome

3. Well resisting active shaft: High grade No. 45 carbon wrought steel.

4. Cutter blade: Cr12 mould steel with quenched treatment

5. Precision: shafts are tooled by grinding machine at least twice. Rollers are CNC processed.

5. About us

We are professional in making roll forming machines since 2003.

Company occupies 6650, in which 5650 for workshops.

Capacity: 12-15 sets/month

Delivery: in only 5-8 weeks for urgent order

Have our own tool center. 12 sets CNC machines.

Over the past 10 years, our R&D members dedicated in make better machines.

6. We garantee:

Machine lifetime service

Technician overseas services.

Material

2. Components of machineDecoiler

3. Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting - Product to Run Out Table

4. Electric elements: Mitsubishi PLC & transducer from Japan.

1. Electric elements: Mitsubishi PLC & transducer from Japan.

2. Anti-rust roller: High grade No. 45 forged steel. Plated with 0.05mm hard chrome

3. Well resisting active shaft: High grade No. 45 carbon wrought steel.

4. Cutter blade: Cr12 mould steel with quenched treatment

5. Precision: shafts are tooled by grinding machine at least twice. Rollers are CNC processed.

5. About us

We are professional in making roll forming machines since 2003.

Company occupies 6650, in which 5650 for workshops.

Capacity: 12-15 sets/month

Delivery: in only 5-8 weeks for urgent order

Have our own tool center. 12 sets CNC machines.

Over the past 10 years, our R&D members dedicated in make better machines.

6. We garantee:

Machine lifetime service

Technician overseas services.