High Quality Qt4-15 Hydraulic Full Automatic Cement Block Hollow Brick Making Machine

Shandong Xinming International Trade Co., Ltd.- After-sales Service:Our Engineer Is Able to Your Factory for Service

- Warranty:2 Years

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

Base Info

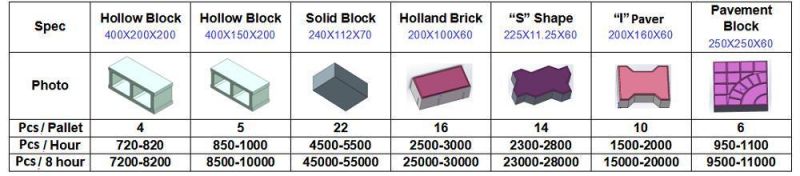

- Model NO.:QT4-15

- Mold Period:15seconds

- Vibration Force:35.5kn

- Color:Optional

- Mixer:Js500

- Power:31.2kw

- Vibration:Table Vibration

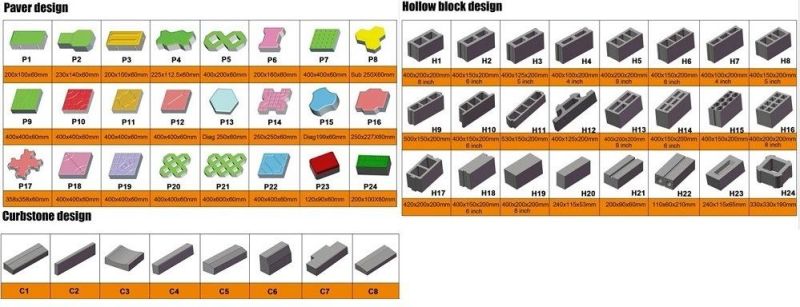

- Mould:Customized

- Hydraulic:Hydraulic Pressure

- Pallet Size:850*550*20 mm

- Shaping Time:10-15 Seconds

- Labor:2-3 Workers

- Silo:50t

- Block Material:Sand, Cement, Cinder, Stone etc

- Pallet Need:as Customer Required

- Transport Package:Nude in Container, LCL

- Specification:4300*2150*2650mm

- Trademark:XINMING

- Origin:Shandong. China

- HS Code:8474802000

- Production Capacity:500PCS,Month

Description

Packaging&Shipping

Packaging&Shipping

Our Service

Pre-sale

<1>. Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

<2>. Device model choice (recommend the best machine according to the raw material, capacity and the size of brick),

<3>. 24 hours on-line service,

<4>. Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you.

Sale:

<1>. Update the production scheduling in time,

<2>. Quality supervision,

<3>. Product acceptance,

<4>. Shipping on time.

After-sale:

<1>. The engineer will guide to carry out the plant at the clients side if needed,

<2>. Set up, fix, and operate,

<3>. Offer training to the operator until they are satisfied at clients side,

<4>. Skill support the whole using life,

<5>. Recall clients regularly ,get feedback in time ,keep well communication with each other.