Pipe Making Machine SSAW Automatic Spiral Welded Tube Machine; Oil Mill

Taiyuan Huaye Equipment Research Institute (Co., Ltd.)- After-sales Service:Available

- Warranty:1 Year

- Pipe Material:Carbon Steel

- Condition:New

- Customized:Customized

- Application:Industry

Base Info

- Model NO.:LH2000-2540-25

- Type:Pipe Welding Machine

- O.D.:711-2540mm

- Thickness:8-25mm

- Max. Coil Weight:35ton

- Material:Q235

- Coil Width:800-2000mm

- Coil O.D.:1500-2000mm

- Coil I.D.:610-760mm

- Transport Package:in Nude

- Trademark:HUAYE

- Origin:China

- Production Capacity:15-30,Year

Description

Basic Info.

Model NO. LH2000-2540-25 Type Pipe Welding Machine O.D. 711-2540mm Thickness 8-25mm Max. Coil Weight 35ton Material Q235 Coil Width 800-2000mm Coil O.D. 1500-2000mm Coil I.D. 610-760mm Transport Package in Nude Trademark HUAYE Origin China Production Capacity 15-30/YearProduct Description

Introduction:

Introduction:Spiral Welded Pipe Making Equipment is mainly used to produce spiral steel pipes. The steel coils are unfolded and leveled by the spiral welded pipe mill. Then they are sent to the forming machine in a certain angle. Supplemented by a certain angle, the continual pipes are formed in the three-roll rolling machine. Continual spiral welding is performed by submerged-arc welding machine.

The products spiral welded pipes can be used in fluids transmission service and ordinary structure supports.

Reference Project

TheΦ2200 × 22mm spiral welded pipe mill is to uncoil the steel coil into steel strip which is formed by forming machine to make spiral welded pipe. Φ406-Φ2200 spiral welded pipe mill apply front swing type mill. The spiral welded pipes are mainly used as delivery pipeline for petroleum, natural gas, water, coal gas, as well as structural pipe and piling pipe.

Machine parts in the working line

1) Uncoiled

2) Pinching & leveling machine

3) Manual/Electrical roll

4) End - Cutting & butt-welding machine

5) Rotary shear

6) Delivery machine

7) Guide board

8) Forming unit

9) Front bridge

10) Inside/outside welding device

11) Rear bridge

12) Flying saw cutter

13) Buried parts

14) Hydraulic system

15) Electric system

16) Inside/outside welder

17) Butt-weld car

18) Plasma cutter

19) Weld flux processing device

20) Beveling & end-facing machine

21) Hydraulic tester

22) Finishing equipment

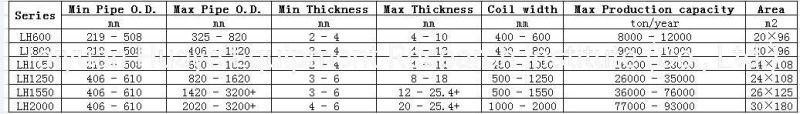

Model