Best Price Active Lime Production Line with Lime Rotary Kiln for Steel Plant

Xinxiang Great Wall Machinery Co., Ltd.- Warranty:One Year

- Application:Lime Production Plant, Cement Plant, Hydrogen Calc

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Kiln Slope:3.5~4%

Base Info

- Model NO.:Lime Production Line

- Diameter:φ1.8~φ4.8 M

- Spare Parts:Rotary Kiln Tyre, Girth Gear, Kiln Support Roller

- Transport Package:Standard Packaging

- Specification:Capacity: 200-1200t,d

- Trademark:CHAENG

- Origin:Xinxiang City, Henan Province, China

- Production Capacity:5000 PCS , Year

Description

Basic Info.

Model NO. Lime Production Line Diameter φ1.8~φ4.8 M Spare Parts Rotary Kiln Tyre, Girth Gear, Kiln Support Roller Transport Package Standard Packaging Specification Capacity: 200-1200t/d Trademark CHAENG Origin Xinxiang City, Henan Province, China Production Capacity 5000 PCS / YearProduct Description

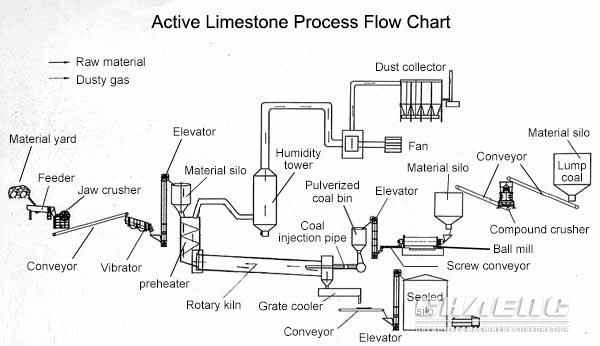

Product descriptionThis active lime production line is a complete line that includes vertical preheater, rotary kiln, grate cooler, air treatment system, raw material conveyor system, finished product conveyor system, raw coal grinding system, and so on. DCS central control system is employed to make concentrated operation management. CHAENG can undertake the 200-1500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging --- " turnkey" service with production capacity and standard achieved.

Process description

Qualified limestone (20 ~ 50 mm) are lifted by bucket elevator to top silo of preheater. There are two level indicators (up and down) controlling the feeding amount, then they are separated averagely into preheaters' individual rooms. The limestone's temperature rises to about 900ºC heated by kiln flue gas of 1150ºC, about 30% of them are decomposed, and they come into the rotary kiln by hydraulic rod, where the limestone decomposed into CaO and CO2. The decomposed limestone are put into the cooler, where its temperatures drops to 100ºC and released. The hot air (600°C) will come to kiln after heat exchange, and mix with coal gas for mixture combustion. The exhaust gas is released by the blower into bag deduster through multi-pipe cooler, then into the chimney though exhaust blower.The limestone from the cooler will be transported to the limestone final product silo through vibrating feeder, chain conveyer, bucket elevator, belt conveyer.

Active lime production line characteristics

1. Large production, maximum capacity can reach 1500t/d

2. Quality of final product is well-distributed, and over-sintering is no more than 8%.

3. Activity of lime can reach 400ml

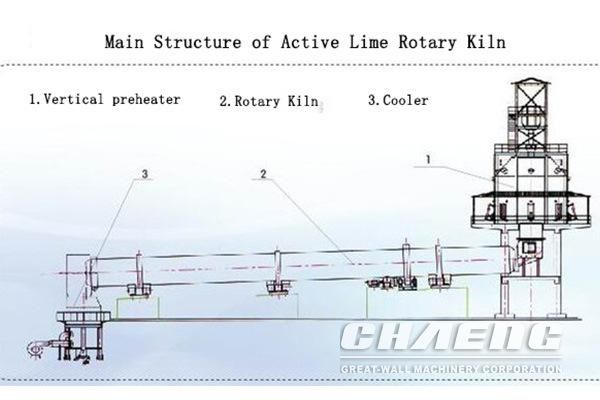

Main structure of activity lime production line

Main structure of rotary kiln:

1.Body

2.Riding wheel

3.Gear ring

4.Tire

5.Transmission device

Main structure of vertical cooler:

Grate bar and discharge device for big block

Cooling chamber lower the cooler

Support Device

Main structure of vertical preheater

Upper feeding system: upper material bin, feeding chute

Preheater body: preheater chamber, suspension device

Stacker device: stacker part, frame, connecting rod.

Hydraulic system

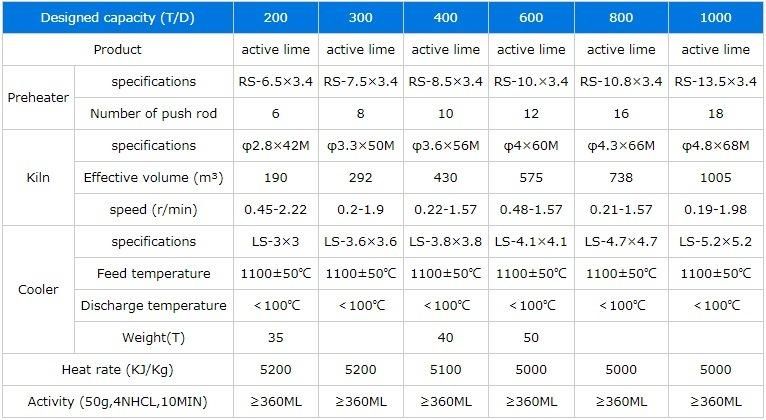

Specifications

Projects

In 2014 , a building material factory from guangxi province of China purchased a lime production line with annual output of 400,000 tons. The main equipment includes φ4.0×60m rotary kiln, φ2.4×4.75m coal mill, 5000 m² bag type dust collector. And all of these equipment were made by CHAENG independently, and CHAENG provided installation and commissioning guidance.

About CHAENG

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel, Voestalpine and ASGT.