CNC Bending Machine for Aluminum Profiles

JINAN YUEFENG MACHINERY CO., LTD.- After-sales Service:Yes

- Warranty:2 Years

- Condition:New

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:CNC

Base Info

- Model NO.:LWYJ-CNC-20T

- Voltage:380V

- Power:5.2kw

- Roller Speed:0-15 Rpm

- The Maximum Radius of The Roller Mold:200mm

- Roller Diameter:60mm

- Center Distance of Fixed Shaft:350-750mm Adjustable

- Maximum Thrust of Y-Axis Cylinder:20 Tons

- Positioning Accuracy of Y-Axis Cylinder:Plus or Minus 0.1mm

- Maximum Torque of X-Axis and Y-Axis:2300 N.M

- Minimum Processing Radius:≥60mm (The Radius Depends on The Material)

- The Largest Section:150mm * 150mm

- External Dimensions of The Host:1100mm*1300*1500

- Overall Dimensions of The Operating Box:500*510*1500mm

- Whole Machine Weight:1000kg

- Transport Package:Wooden Box

- Specification:500*510*1500mm

- Trademark:YueFeng

- Origin:China

- HS Code:8477800000

- Production Capacity:40 Window Per Day

Description

1.The machine applies to bending several kinds of metal profiles to appears arc shape, such as iron, copper and aluminium.

2.Adopts special arc-processing software, can detect the data of rebound, and then eliminate the rebound.

3.Single-curve bendable shapes: C-shaped, U-shaped, multi-curved bendable ellipse, input up to 10 radii at one time (can be increased)

4.Positioning accuracy: Y-axis repeated positioning accuracy ±0.1mm, X-axis positioning accuracy ≤0.5mm

5.The profile can be rolled and formed at one time; it can also be bent and formed as many times as necessary.

Machine parameters

| Power | 5.2KW |

| Voltage | 380V 50HZ |

| Roller speed | 0-15 rpm |

| The maximum radius of the roller mold | 200mm |

| Roller diameter | 60mm (special materials, heat treatment processing) |

| Center distance of fixed shaft | 350-750mm adjustable |

| Maximum thrust of Y-axis cylinder | 20 tons |

| Positioning accuracy of Y-axis cylinder | plus or minus 0.1mm |

| Maximum torque of X-axis and Y-axis | 2300 N.m |

| Minimum processing radius | ≥60mm (the radius depends on the material) |

| The largest section of the profile that can be processed | width * height = 150mm * 150mm |

| External dimensions of the host | 1100mm*1300*1500 |

| Overall dimensions of the operating box | 500*510*1500mm |

| Whole machine weight | 1000kg |

Details of the machine:

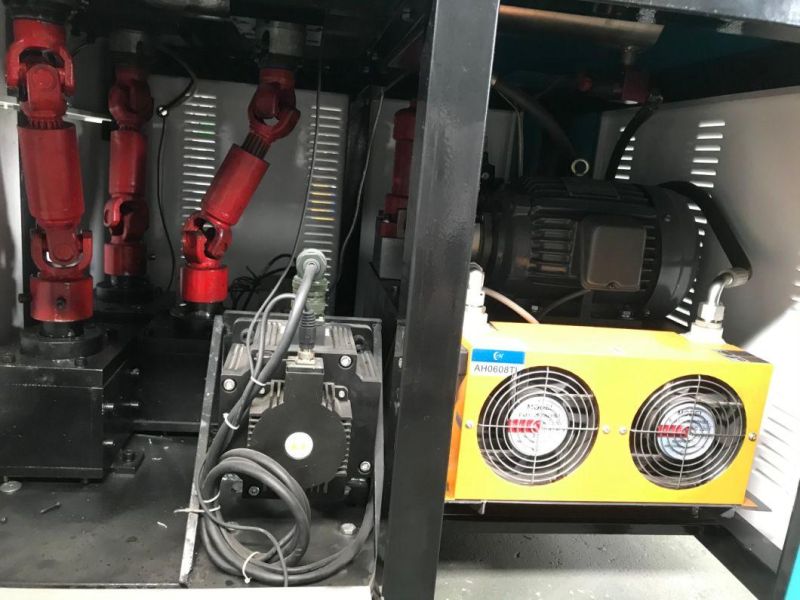

1.All electrical components: French "Schneider", South Korea Autonics positioning detection switch

2.Taiwan Delta Servo Motor,The left and right rotation of the X axis is controlled by Taiwan Delta servo motor: the torque is constant, and the rotation speed of the X axis and Y axis is synchronized.

3.Original German imported BMEG servo proportional valve,Control direction and flow rate, fast response, accurate flow control(Ordinary arc bending machine only has hydraulic station)

4.Light Shed Ruler: China Famous Brand Guangzhou "SINO"It adopts dual-drive grating ruler, equipped with anti-interference module, and has good arc repeatability.

5.American Banner Encoder

6.Yuken Hydraulic System

7.Nylon mold and shaping belt to prevent profile friction(Customized according to customer's profile samples and profile drawings)

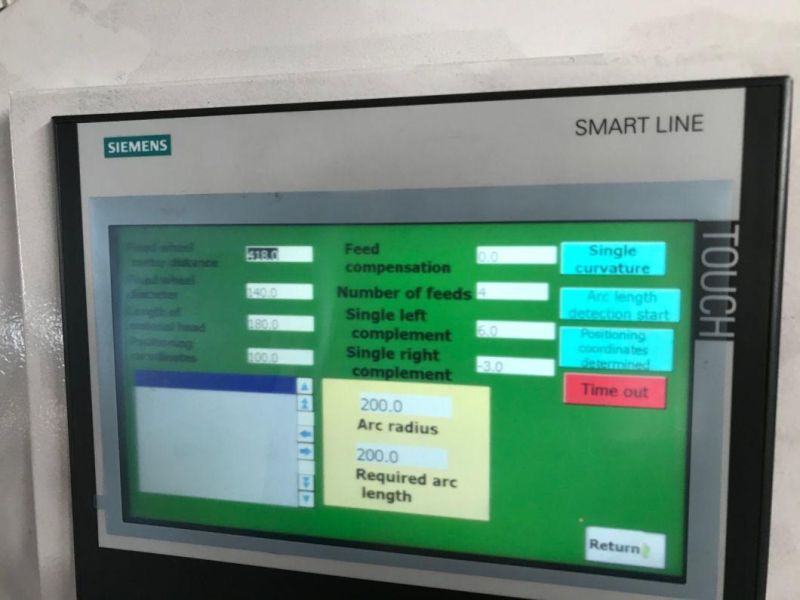

8.German "Siemens" CNC system "10-inch LCD screen

The software has the following auxiliary functions:

1 Profile rebound compensation function

(The arc radius of the first profile is not accurate, and the second profile can be accurately bent according to the calculation results)

2 Auxiliary calculation: According to the chord length and chord height, the radius and arc length can be obtained. The blanking size is the arc length plus the length of the two material heads.

3.Semi-automatic manual function: Inaccurate arc size can be adjusted by manual function to find out the accurate compensation number, so that the arc standard can be bent into

4.Each arc can be stored according to the formula between 0-9 A-Z

FAQ

1.Are your company a trading one or a factory?

Factory + trade (integration), 36 years' focusing on Upvc,Aluminum Window and Doors Equipment ,insulating glass equipment and curtain wall equipment.

2.After an order is placed, when to deliver?

♦ Generally about 15 days, If we have inventory, we can arrange shipment within 5 days.

♦ Please be aware that our production lead times depend on specific items and item quantities.

3.What about the warranty with after - sales services?

♦ 24 months warranty. Besides,we can help you to solve your problem freely;

♦ After the warranty, the professional after-sale service team will provide perfect technical support,and help customer solve problem encountered while using our product, handles guest problems and complaints in a professional and timely.

4.What about the services and product' quality?

♦ Each machine must be carried out 100% quality examination and test before shipment.

♦ And all machines meet ISO and CE certification.

5. We don't know the machine operation, what should we do?

♦ We can send engineer to your place, or we provide video training to show you how to install & operate, let engineer help you online.