Customized Color Steel Roll Forming Machine in China

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:steel roll forming machine

- Customized:Customized

- Usage:Roof

- Transmission Method:Machinery

- Type:Steel Roll Forming Machine

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Advantage:Use Widely

- Warranty:12 Months

- Forging Forming Method:Mold Forging

- Name:Colored Metal Steel Panel Roll Forming Machine

- L * W * H:6500mm * 1600mm * 1500mm

- Machine Weight:About 2.5t

- Frame Materials:300h Steel

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX1080

- Trademark:DX

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Month

Description

Basic Info.

Model NO. steel roll forming machine Customized Customized Usage Roof Transmission Method Machinery Type Steel Roll Forming Machine Power Source Hydraulic Pressure Feature High Efficiency Advantage Use Widely Warranty 12 Months Forging Forming Method Mold Forging Name Colored Metal Steel Panel Roll Forming Machine L * W * H 6500mm * 1600mm * 1500mm Machine Weight About 2.5t Frame Materials 300h Steel Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX1080 Trademark DX Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per MonthProduct Description

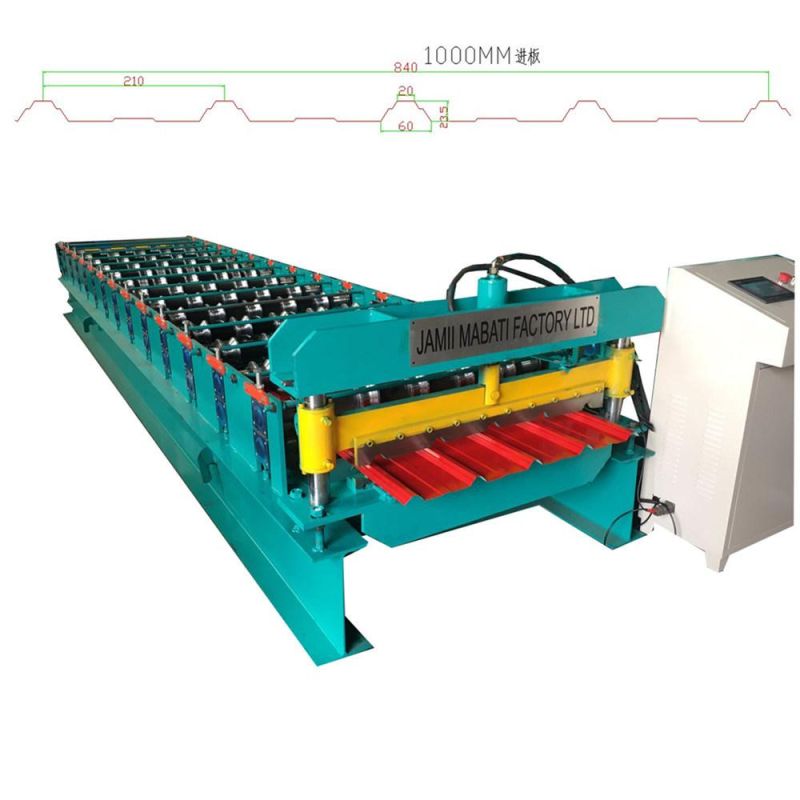

Customized color steel roll forming machine in ChinaPanel drawing and pictures for your reference.

1.Equipment detailed parameters:

1.Equipment detailed parameters:| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.3-0.8mm |

| 3.Feeding width: | 1000mm |

| 4.Effective width | 840mm |

| 5.Main motor power | 4kw |

| 6.hydraulic pump power | 4kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | 13steps |

| 9.Main frame | 300H Steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | PLC control system with touch screen |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 10-12m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 6800*1500*1400mm |

| 17. Machine weight | About 2.5ton |

| 18.Power supply | 380v,3phase,50hz or accodring to customer request |

2.Working flow:

Uncoiler-- roll forming machine-- PLC control box-- hydraulic cutter- receiving table

3.Our Services

1 One year quality gurantee and lifeong technical support.

2 Once some parts go wrong in one year, we can send one to you.

But you shoul pay for seafreight.

3 On-siting training or maintance available. But you should pay for tickets and salary.

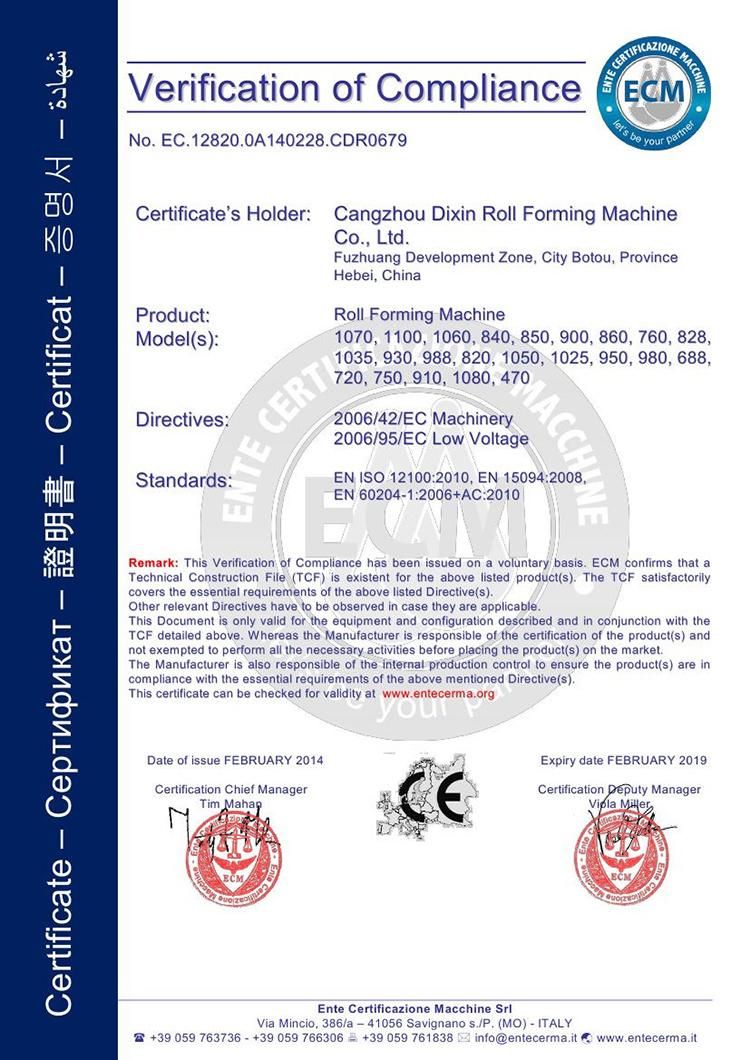

4.Certifications

Our machines have been certificated by TUV (factory certification) and CE (quality certification)

5.Our company information

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc. We can satisfy the different needs of different markets.

Warmly welcome to China to visit our factory and select the machines you need. Our address, Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China.

Any questions, we will reply to you promptly.

WARMLY WELCOME TO OUR NEW FACTORY!

A: - What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

B: - Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C: - Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D: - What is the after- sale service?

- About the after-sales service. We can send technician to your country to fix the machine. The buyer should bear all the cost including: Visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.The warranty is one year. And we will provide the technical support for the whole life. It is free to maintain the machine the first year after buying, including changing the main components. The first year hence, you will pay for our technician $50 per day to maintain the machine. And the components are not free, if you need to get it from us.

E: - Any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

F: - Can you accept OEM?

- We can accept OEM.

G: - Any certification:

- Yes, we have CE TUV BV certification.

We also can design and produce machine according to customer's requirement