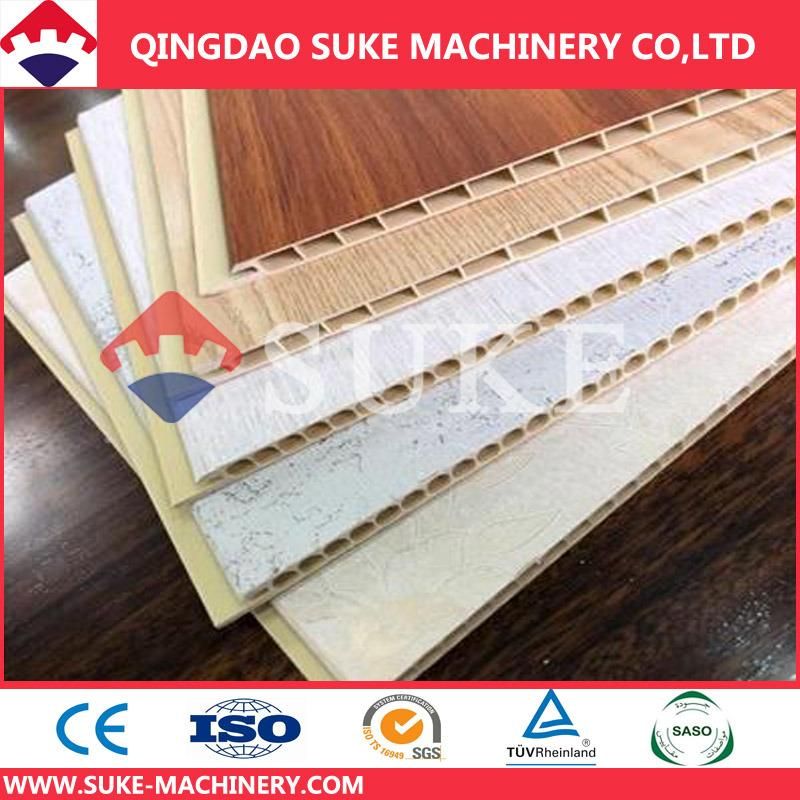

Free Installation PVC Ceiling Panel Board Production Line Extrusion Making Machine Machinery

Qingdao Suke Machinery Co., Ltd.- Warranty:12monthes

- Product Type:PVC Profile

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJSZ

- Condition:New

- Customized:Customized

- Automation:Automatic

- Computerized:Computerized

- Material:Stainless Steel

- Power Supply:380V Three Phase

- Inverter:ABB

- Intelligent Temperature Controller:Omron From Japan

- Control System:PLC Control System

- After Sale Service:Life Long with Professional After Sale Team

- Machine Type:Twin Screw Extruder

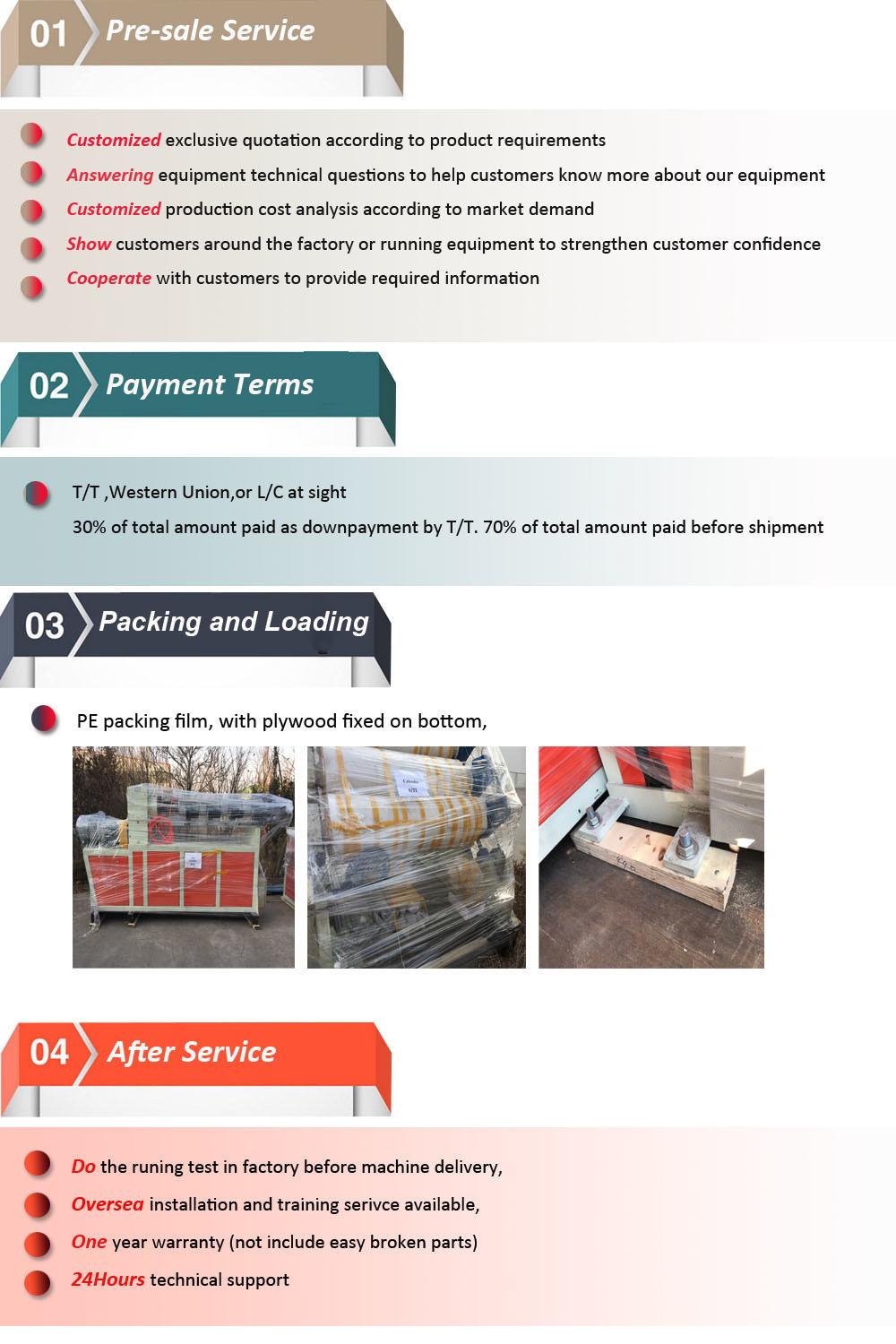

- Transport Package:PE Film and Wooden Package

- Specification:CE ISO9001

- Trademark:suke

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:25sets,Year

Description

Brand Name: SUKE

This line is used to produce PVC Ceiling Panel, which used on roof and wall decoration,

It needs twin screw extruder with power material.

Raw material is PVC power, or with wood power and additives.

- Conical Twin Screw Extruder:

- Vacuum calibrating table:

Adopts powerful turbo cooling system, easy to achieve satisfactory cooling effect. According to different moulds and different customer requirements, the vacuum calibrating table can be optional as 4m, 6m. - Haul off machine:

Adopts special lifting technology, and has the features of stable running, reliable working, powerful hauling etc, - Cutting machine:

the moving speed of the cutting unit is synchronized with hauling speed. Through prseting,the cutting unit is capable for automatic cutting with fixed length. Dust recycling device is also equipped.

- Double Screw Extruder 1 unit

- Mould 1 set

- Shaping Machine 1 unit

- Haul-off Machine 1 unit

- Cutting Machine 1 unit

- Stacker 1 unit

- Crusher 1 unit

- Mixer 1 unit

- Pulverizer 1 unit

- Air Compressor 1 unit

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

- Delivery Time: 40 days after receipt of prepayment.

- Packing Method: Packing film or wooden case

- Guaranteed Time: 12 months

- When machine finished, we will invite client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

- When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

Extruder | SJZ51/105 | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

| Main Motor Power | 18.5kw | 30kw | 37kw | 55kw | 110Kw |

| Production capacity | 80-100kg/h | 100-180kg/h | 150-200kg/h | 200-300kg/h | 550-700kg/h |