Porcelain Tile Manufacturing Machine, Terrazzo Tiles Machinery, Floor Tiles Machine

Guangxi Hongfa Heavy Machinery Co., Ltd.- Warranty:1 Year Warranty

- Certification:CE

Base Info

- Model NO.:HFT300 floor tiles machine

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- Weight:5 Tons

- Support Finished Tiles Size:300X300mm , 400X400mm , 600X600mm

- Raw Material:Cement Stone Powder Pigmment

- Productivity:2500PCS, 8 Hours

- Day Productivity:200-250sqm , 8 Hours

- Transport Package:Ship by Sea

- Specification:3000x1800x1950mm

- Trademark:HONGFA

- Origin:Guangxi, China

- HS Code:8474802000

- Production Capacity:Floor Tiles 300X300X30mm, 2200 PCS, 8 Hours

- Package size per unit product:310.00cm * 185.00cm * 195.00cm

- Gross weight per unit product:5200.000kg

Description

Mixer with hopper, mould(s), manual tile machine, trolley, color sprayer etc.Floor Tiles Machine Main components

HFT300 tile machinery main components

1.Host machine

2.Host motor

3.Hydraulic station

4.Tiles Mould

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

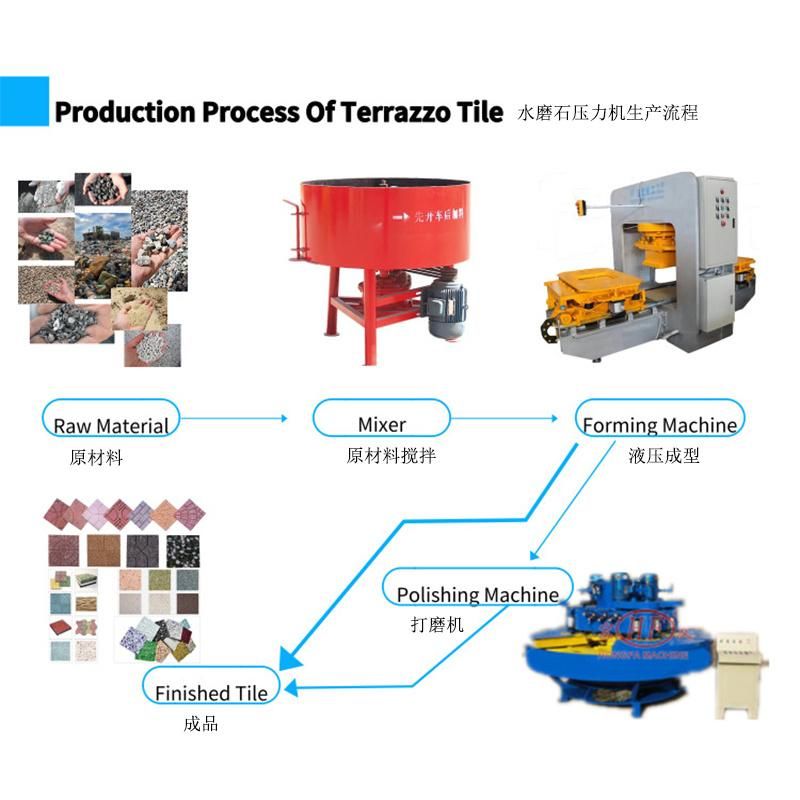

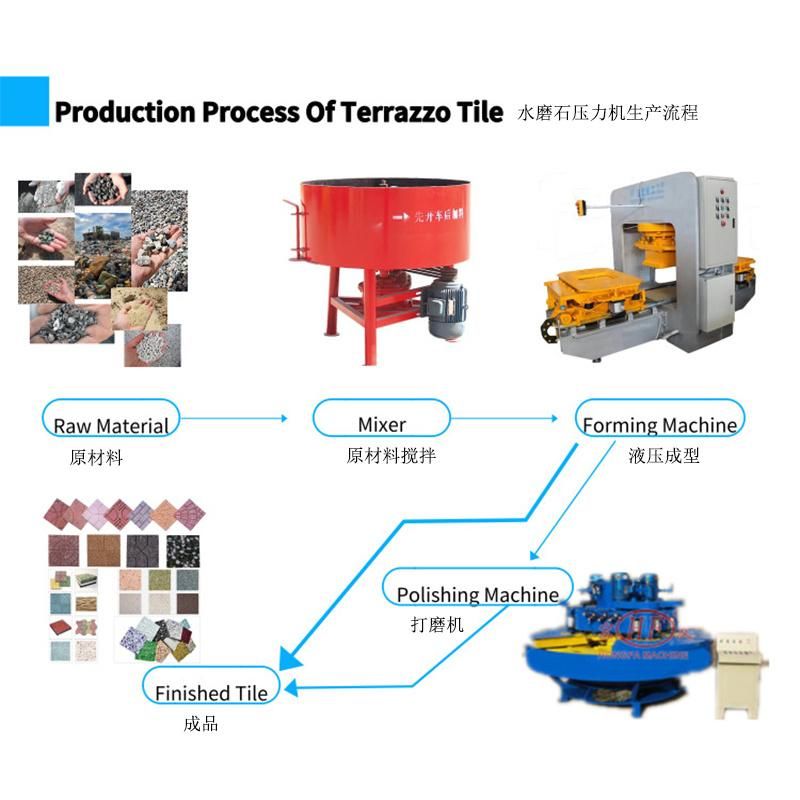

How to produce floor tiles?

Production process of HFT300 terrazzo tile making machine:

Work flow: Elevating--- Mixing --- Fixed-quantity filling --- Pressure forming --- Mould unloading --- Forming tiles ---Onto the tiles shelf --- --- Stacking --- Curing (24 hours)--- Polishing --- Finished products.

1. At first,the raw materials are put into the bucket elevator, then deliver to the rolling mixer,at this time,you must add some water into it.

2. After mixing, the mixture come into the dosing feeder,then,measurable mixture that one tile need will put down on the mould below through a small hole.

3. Then,a tile can be formed by high pressure,the pressure is about 150 tons. So the produced tile is very stable and dense.

4. By the way,the tile need to dry out for about 10 days.Then you can paint.

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

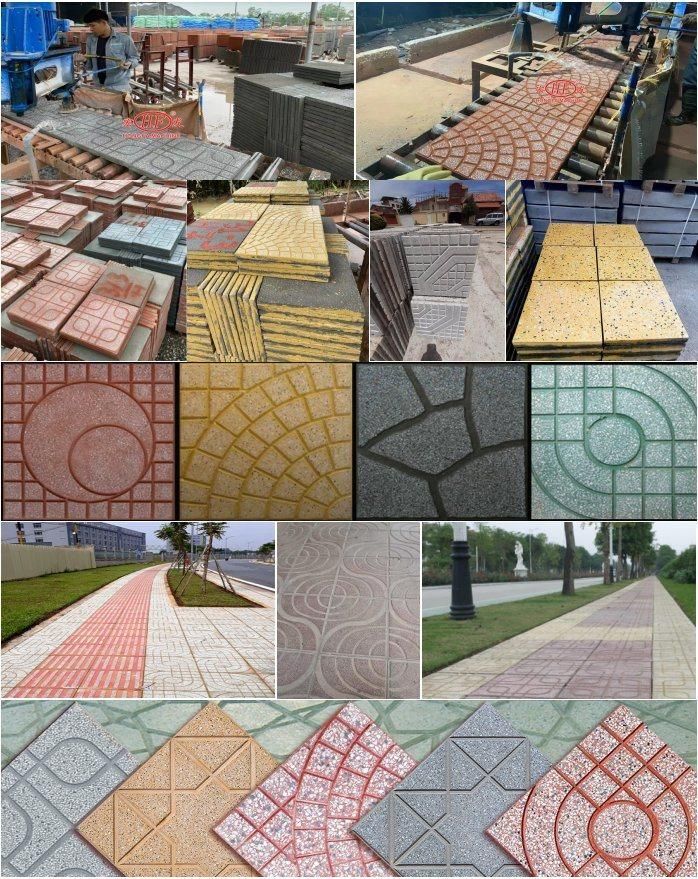

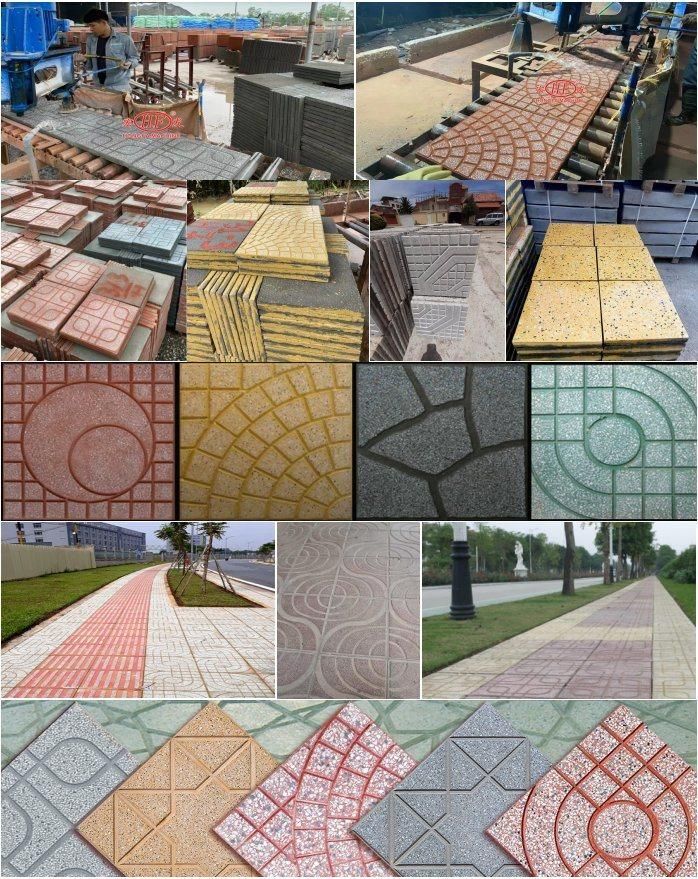

Terrazzo application scenarios

Hongfa Machinery Group Main Products :

Automatic Block Making:

HFB5250A HFB5220A HFB5230A HFB5200A HFB5115A HFB5120A HFB5100A HFB580A HFB575A HFB570A

Semi-automatic:

HFB521M HFB520M

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

HFB543S SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~300000M3/Year

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

HFT300 tile machinery main components

1.Host machine

2.Host motor

3.Hydraulic station

4.Tiles Mould

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles MachineHow to produce floor tiles?

Production process of HFT300 terrazzo tile making machine:

Work flow: Elevating--- Mixing --- Fixed-quantity filling --- Pressure forming --- Mould unloading --- Forming tiles ---Onto the tiles shelf --- --- Stacking --- Curing (24 hours)--- Polishing --- Finished products.

1. At first,the raw materials are put into the bucket elevator, then deliver to the rolling mixer,at this time,you must add some water into it.

2. After mixing, the mixture come into the dosing feeder,then,measurable mixture that one tile need will put down on the mould below through a small hole.

3. Then,a tile can be formed by high pressure,the pressure is about 150 tons. So the produced tile is very stable and dense.

4. By the way,the tile need to dry out for about 10 days.Then you can paint.

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles MachineTerrazzo application scenarios

Terrazzo Floor Tile Are Everywhere In Our Life→→→

Function of Terrazzo Tile Making Machine:

• Swimming Pool, Courtyard, Civil Architecture

• Square,Sidewalk,

• Hospital,Kitchen,Washroom,School, Public Institution, Office Building

Hongfa Machinery Group Main Products :

Automatic Block Making:

HFB5250A HFB5220A HFB5230A HFB5200A HFB5115A HFB5120A HFB5100A HFB580A HFB575A HFB570A

Semi-automatic:

HFB521M HFB520M

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

HFB543S SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~300000M3/Year

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine

Porcelain tile manufacturing machine, terrazzo tiles machinery, Floor Tiles Machine