EPS Precast Concrete Wall Panel Machinery

OYADE (Shandong) Machinery Equipment Co., Ltd.- Product Type:Build Material

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO

- Condition:New

Base Info

- Customized:Customized

- Item:Concrete Wall Panel Machine

- Panel Length:2440mm-3300mm

- Product Width:610mm

- Equipment Capacity:30, 000sqm~500, 000sqm Per Year

- Machine Features:High Equipment, Low Failure Rate

- Panel Usage:Interior Wall ,Floor ,Exterior,Roof,Ceiling

- Steel Plate:Cold-Roll Steel Sheets

- Mixer Capacity:1.5,2.0,2.5,3

- Injection Way:by Pump

- Transport Package:Bulk Packing

- Specification:5containers

- Trademark:OYADE

- Origin:China

- HS Code:8474802000

- Production Capacity:300sets,Year

Description

Lightweight Aggregate EPS particles ( Particle size 3-5mm after forming ) Ceramsite (large than 5mm ),Pumice stone(5-12mm) Perlite ,Tire pellets,Construction rubbish,Rice husk Chemical additives Like forming agent , water reducer ,cellulose ether ect.

Product type :solid wall panel and composite wall panel Size :2400-3000mm *610*45-200mm Feature : 1.large capacity than horizontal mould car 2.automatically and more effecient 3.Small land space .vertical type mould car can save land area 4.About demoulding : each time can de-mould 20 pcs panel ,Saving working strength

2.need3-4person,

3.30 minutes/car

2.need 1-2person,

3. need 10-15minutes /car Remark: Only suitable for Type 1 mould car without steel plate ,also recommand to big capacity.

4.Panel typeFinished panel

5.Project

We have been in this line for 15years.We have the most projects in domestic and abroad market,

our main market is middle Aisa, Southeast asia, South America.

6.Factory

2.Machine introduction

Generation 1 vertical mould car

Product type :composite wall panel Size :2400-3000mm *610*45-200mm Feature : 1.large capacity than horizontal mould car 2.Cost saving and easy operation , low maintance rate 3.Small land space .vertical type mould car can save land area 4.About demoulding : Adopt the latest demoul technology, more time saving and labors saving

Generation 2 vertical mould car

Product type : composite wall panel and Solid wall panel Size :2400-3000mm *610*45-200mm Feature : 1.large capacity than horizontal mould car 2.Can produce wall solid wall panel with or without skin board 3.Small land space .vertical type mould car can save land area 4.About demoulding : Each time one pieces

Generation 3 vertical mould car

Product type :solid wall panel and composite wall panel Size :2400-3000mm *610*45-200mm Feature : 1.large capacity than horizontal mould car 2.automatically and more effecient 3.Small land space .vertical type mould car can save land area 4.About demoulding : each time can de-mould 20 pcs panel ,Saving working strength

Type 1 :1pcs /time demould machine

1.1pcs/time2.need3-4person,

3.30 minutes/car

Type 2:New type demould machine

1.2pcs/time2.need 1-2person,

3. need 10-15minutes /car Remark: Only suitable for Type 1 mould car without steel plate ,also recommand to big capacity.

Type 3 automatic demould machine

1.20pcs /time

2.need3-4person,1 person control the PLC ,another two assist demoulding

3.8-10minutes/car

3.Production process

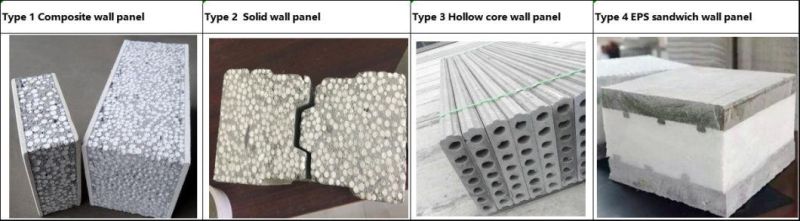

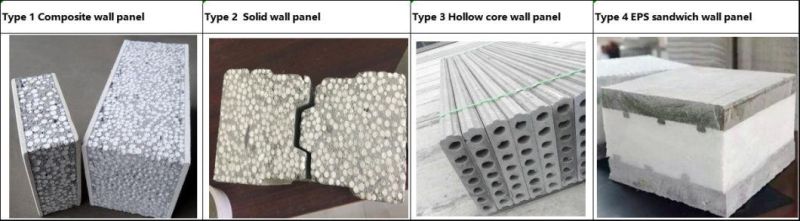

4.Panel type

Finished panel

This kind of machine could produce 4 kinds of panel

5.Project

We have been in this line for 15years.We have the most projects in domestic and abroad market,

our main market is middle Aisa, Southeast asia, South America.

6.Factory