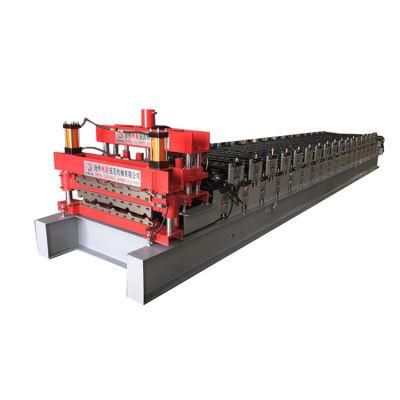

Africa Double Deck Layer Roll Forming Machine/Q Tile and Ibr Trapezoidal Roof Roll Panel Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, CCC, ISO9001

- Condition:New

Base Info

- Model NO.:820,840mm

- Customized:Customized

- Usage:Roof

- Transmission Method:Machinery

- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Warranty:12 Months

- Advantage:Use Widely

- Name:Roof Metal Sheet Rolling Machine

- Processing Material:Aluzinc,Galvanized Steel,Colored Steel Coil

- Material Thickness:0.3-0.8mm

- Effective Width:828,900

- Transport Package:Simple Waterproof Fit for Ocean Ship, Need a 20 Gp

- Specification:CE ISO BV

- Trademark:DIXIN

- Origin:Botou City, Hebei Province

- HS Code:84552210

- Production Capacity:20 Set Per Year

Description

Basic Info.

Model NO. 820/840mm Customized Customized Usage Roof Transmission Method Machinery Type Rolling Machine Forging Forming Method Mold Forging Power Source Hydraulic Pressure Feature High Efficiency Warranty 12 Months Advantage Use Widely Name Roof Metal Sheet Rolling Machine Processing Material Aluzinc/Galvanized Steel/Colored Steel Coil Material Thickness 0.3-0.8mm Effective Width 828/900 Transport Package Simple Waterproof Fit for Ocean Ship, Need a 20 Gp Specification CE ISO BV Trademark DIXIN Origin Botou City, Hebei Province HS Code 84552210 Production Capacity 20 Set Per YearProduct Description

Africa Double Deck Layer Roll Forming Machine/Q tile and IBR Trapezoidal Roof Roll Panel Forming MachineFeatures of our machine

1)Professional designing for manufactures roofing & walling

2)Automatically continually manufactures high quality product with PLC.

3)Easy operation : Directly input the data on the touchable screen.

4)Customers decide the profile of products.

5)Saving time and cost owing to high speed running with hydraulic system.

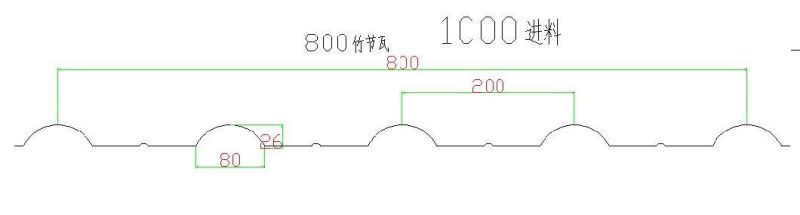

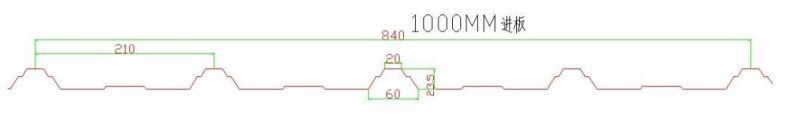

1.Panel drawing as request .

2.Technique parameters

Processing material: aluzinc/galvanized steel/colored steel coil

(1) Material thickness: 0.3-0.8mm

(2) Effective width: customer request

(3) Feeding width: customer request

(4) Main motor power: 5.5kw

(5) Pump power: 4kw

(6) Shaft diameter: 75mm

(7) Forming steps:13 steps.

(8) Roller material: 45# forged steel, with hard chrome plating

(9) Main frame: 300H steel

(10) Medium plate thickness: 16mm

(11) Control systerm: PLC computer control with inverter

(12) Power supply: 380V, 3 Phase, 60Hz or as your requirement

(13) 0veral sized:about 6500mm*1500mm*1300mm

3. Work flow

Manual decoiler-Roll forming machine-PLC control-Hydraulic system -Punching System---Post cut-Stacking

4. Components of production line

No. | Name | Unit | Qty |

1 | Manual decoiler | set | 2 |

2 | Main forming machine | set | 1 |

3 | PLC control system | set | 1 |

4 | Hydraulic pump station | set | 1 |

5 | Post cut | set | 1 |

6 | Electric motor | set | 1 |

7 | Output table | set | 2 |

6. Payment term

TT, you should pay 30% as the deposit on the order day, then pay 70% before delivery when you inspect goods well in factory or by video

7. Warranty

12 months, and lifelong technical support service

8. Installation

If you need, we will send one technician to your factory to install & testing the machine. You should assist the technician to get Visa and pay for flight tickets and local accommodation, and pay 80 USD/day for salary.

9. Package

Standard export package, water-proof package, covered with plastic film

10.Service

One year warranty and lifelong technical support will be provided.

If you come here,we can teach you how to use it on-site for free.If not,We can learn by video.It is easy to operate.

We can send our technicians to you to give you on-site training. The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of USD 80.