Dx 840 Aluminium Color Steel Crimping Curving Roofing Sheet Roll Forming Machine

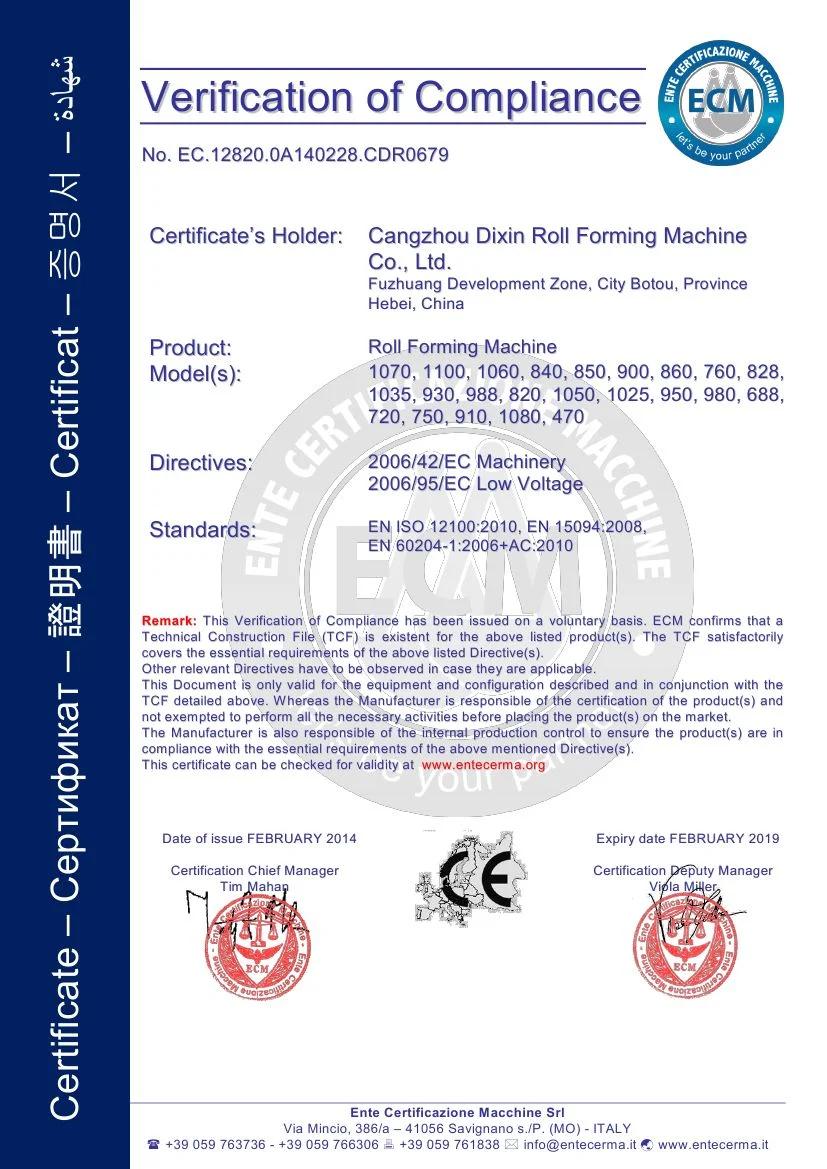

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Certification:CE, CCC, ISO9001

- Condition:New

Base Info

- Model NO.:DX 840

- Customized:Customized

- Transmission Method:Machinery

- Type:Rolling Machine

- Power Source:Hydraulic Pressure

- Feature:Automation

- Advantage:Work Flexible

- Forging Forming Method:Mold Forging

- Name:Arched Roof Forming Machinery, Curving Machine

- Processing Material:Aluzinc,Galvanized Steel,Colored Steel Coil

- Material Thickness:0.3-0.8mm

- Effective Width:840mm

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX 750 840

- Trademark:DX

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Month

Description

Basic Info.

Model NO. DX 840 Customized Customized Transmission Method Machinery Type Rolling Machine Power Source Hydraulic Pressure Feature Automation Advantage Work Flexible Forging Forming Method Mold Forging Name Arched Roof Forming Machinery, Curving Machine Processing Material Aluzinc/Galvanized Steel/Colored Steel Coil Material Thickness 0.3-0.8mm Effective Width 840mm Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX 750 840 Trademark DX Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per MonthProduct Description

Dx 840 Aluminium Color Steel Crimping Curving Roofing Sheet Roll Forming Machine

(1) Processing material: aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Effective width: 840mm

(4) Feeding width: 1000mm

(5) Main motor power: 3 kw

(6) Forming steps: 5 steps

(7) Control systerm: PLC computer control with inverter

(8) Power supply: 380V, 3 Phase, 50Hz

(9) 0veral sized: 2500mm*1300mm*1300mm

Packaging & Shipping

1 Main forming machine and un-coiler is naked.

2 Tighten to container with steel wirerope and welded machine with container by angel iron.

3 PLC system and motor can be packed in waterproof plastic coverage if needed and necessary.

Our Servicesafter-sale service

one year warrantly and lifelong technical suport will be kind and

effective provided.

on-site servicewe can send our technicians to you to give you onsite training.

The training period would be for no more than one week with the

customer paying for the visa, return ticket, food, accommodations

and a daily wage of USD 80.

Company InformationOur enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address, Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China.

CE certification

| 1 | material | colored steel |

| 2 | sheet thickness | 0.2-0.8mm |

| 3 | formed width | 840mm |

| 4 | main motor | 5.5kw |

| 5 | main frame | 300H steel |

| 6 | forming step | 5 steps |

| 7 | diameter of roller | 75mm |

| 8 | roller material | 45# steel |

| 9 | thickness of medium plate | 14mm |

| 10 | voltage | as customer's request |

| 11 | control system | Delta PLC computer control system |

| 12 | machine size | 3500*1300*1300mm |

| 13 | weight | about 1.5 tons |

| 14 | warranty | 12 month |

| 15 | certification | CE TUV BV |