Four Head Welding Machine Seamless Plastic Window Door Machinery Four Heads PVC UPVC Seamless Welding Machine

Jinan Hiwoc Group Co., Ltd.- Certification:ISO, CE

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:HW-WFH-4

- CNC or Not:not CNC

- Voltage:380V

- Air Pressure:0.5~0.8MPa

- Air Consumption:200L,Min

- Input Voltage:220V 50~60Hz or as Customer Need

- Input Power:3kw

- Welding Profile Height:20-120mm or Customized

- Welding Width:120mm

- Welding Range:400-3500mm

- Overall Size:4400×950×1700mm

- Weight:1500kg

- OEM:Support

- Transport Package:Film and Plywood Case

- Specification:5300x950x1700mm

- Trademark:Hiwoc

- Origin:China

- HS Code:84659200

- Production Capacity:1000,Year

Description

Basic Info.

Model NO. HW-WFH-4 CNC or Not not CNC Voltage 380V Air Pressure 0.5~0.8MPa Air Consumption 200L/Min Input Voltage 220V 50~60Hz or as Customer Need Input Power 3kw Welding Profile Height 20-120mm or Customized Welding Width 120mm Welding Range 400-3500mm Overall Size 4400×950×1700mm Weight 1500kg OEM Support Transport Package Film and Plywood Case Specification 5300x950x1700mm Trademark Hiwoc Origin China HS Code 84659200 Production Capacity 1000/YearProduct Description

Four Head Welding Machine Seamless Plastic Window Door Machinery Four Heads PVC UPVC Seamless Welding MachineFeature

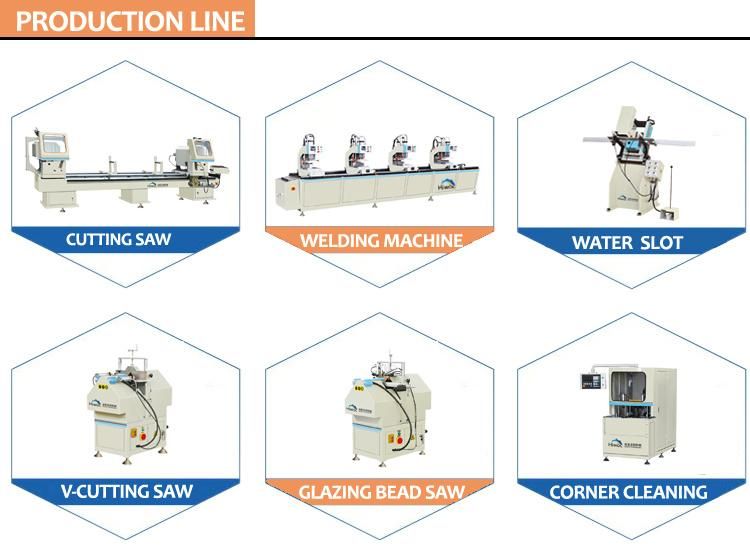

1.Four heads can work seperately or linkage.

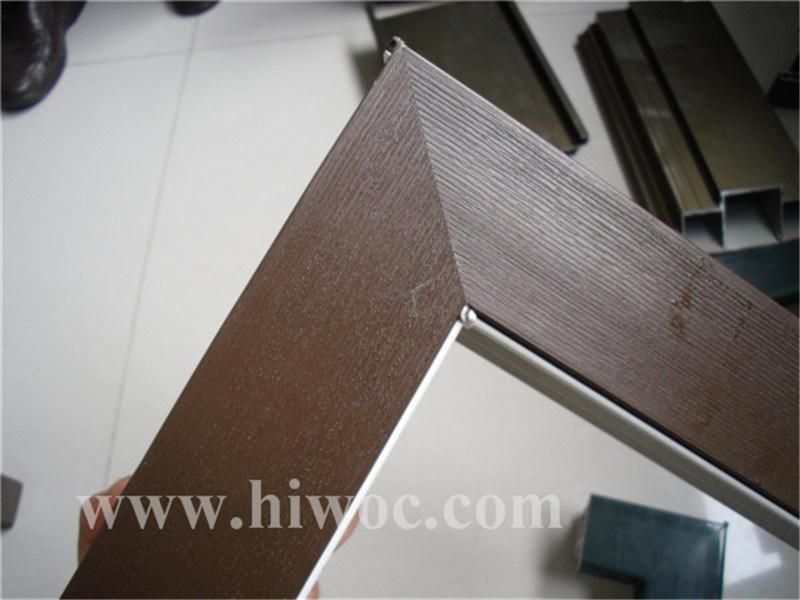

2. Can control the welding gap size strictly, so the surface welding is very flat and beautiful.

For profile seamless welding(0.2mm welding seam).

3. Profile clamp with cutters, welding seam adjustable within 0.2-2mm.

4. Specialized for V-welding, T-welding, H-welding and ⊥, ∟,+,∠ shapes and so on.

Can avoid complicated adjustment.

5. Right head could be 30° ~ 180° arbitrary angle welding

6. Can respectively meet the common profile and colored profile processing requirement.

Applicable for weld color profile, both the upper and bottom side will flash disposable cleaning is

completed.

7.Imported square bearing system guarantee clamping, heating plate, locating plate moving

precision&reliable performance. Locating plate can slide along square guide, increasing locating precision.

8. The cutter blade tool adopt alloy materials, the blades could realize automatic,support change blades.

9. The whole machine body adopt high inflexibility structure welded, high bearing capacity, not transform.

10.The moving part welding plate use circular orbit support, up and down movement use square guide, can use longer and more stability.

11.The bottom position square guide positioning design. Positioning with high precision. Welding size is standard, ensuring higher reliability.

12. Automatic blowing device, blowing all the welding block once.

13. Easy-change for special fixture, increased corner strength and cleaning appearance.

14.PLC control the welding action and program with high reliability.

15. Parameters can be set to meet various profiles processing requirement.

16. on the left bottom, we will add Man-machine interface screen. It can show heating time, welding time, feeding delay time, blowing time and Pressure clamp uplift time and so on.

17. The machine is using double clamping, make sure more accurate and precision.

18. Pneumatic brake device

| Parameter | |

| Air Pressure | 0.6~0.8MPa |

| Air consumption | 260L/min |

| Input Voltage | 220V 50~60Hz or As Customer need |

| Input Power | 4.5Kw |

| Welding profile height | 20-110mm |

| Welding Width | Max 120mm |

| Welding range | 400-3500mm |

| Overall size | 4400×950×1700mm |

| Weight | 1500kg |

| Main accessory | |

| PLC | Taiwan Delta |

| Solenoid valve | Airtec |

| Cylinder | PC(FESTO Joint Venture Brand) |

| Motor | Anhui Sanyang (Best Chinese Motor Brand) |

| Air Filter Device | Huatong |

| Electrical Button and Switcher | Schneider |

| AC Contactor and Circuit Breaker | Schneider |

| Temperature Controller | Japan Omron |

| Standard accessory | |

| Heat plate | 8pcs |

| Teflon cloth | several |

| Complete tooling | 1set |

| Certificate | 1pc |

| Operation Manual | 1pc |