Plastic Board Making Machine Production Line

Qingdao Suke Machinery Co., Ltd.- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Single-Screw

- Certification:CE, ISO

- Condition:New

- Customized:Non-Customized

Base Info

- Model NO.:sj90,30

- Material:Stainless Steel

- Mould for Sheet/Board:T Type

- Button:Schneider

- Intelligent Temperature Controller:Omron

- Inverter:ABB

- Warranty:12monthes

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Request

- Raw Material:Plastic Material

- Extruder Type:Single Screw Extruder

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:8477800000

- Production Capacity:50pics,Year

Description

Basic Info.

Model NO. sj90/30 Material Stainless Steel Mould for Sheet/Board T Type Button Schneider Intelligent Temperature Controller Omron Inverter ABB Warranty 12monthes After Sale Service Life Long with Professional After Sale Team Machine Color as Request Raw Material Plastic Material Extruder Type Single Screw Extruder Transport Package According to Your Requirement Specification ISO9000 CE Trademark SUKE Origin Qingdao, China HS Code 8477800000 Production Capacity 50pics/YearProduct Description

Plastic Board Making Machine with CE Certified (SJ)

Application:

Transportation: Such as steamship, aero plane, carriage, train compartment, roof Shed, case core layer, inner upholster, etc.

Architecture: Such as building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust board, ceiling plate, etc.

Advertisement: Such as screen printing, computer lettering, ad board, etc.

Industry: Such as chemical industry antisepticising project, thermoforming, for refrigerator, for temperature keeping, for environment protection, etc.

Other applications: Such as mould plate, sports equipment, breeding equipment, seashore wet-proof facility, water-fast material, art material, various interlayer, etc.

Production scope: Thickness1-20 width 800-2050mm

Our Board Machine/Board Extruder/Board Extrusion is good in quality and competitive in price. We manufacture this line under the brand name "SUKE", and also supply OEM, ODM service according to your requirement.

If you want more details about this Board Machine/Board Extruder/Board Extrusion, please contact us.

Related Category: Board Machine, Board Extrusion, Board Extruder, Solid Board Production Line

| Width of Sheet : | 400-2500(mm) |

| Thickness of Sheet : | 0.2-50(mm) |

| Max.output : | 30-600(kg/h) |

| Max.line speed : | 25(m/min) |

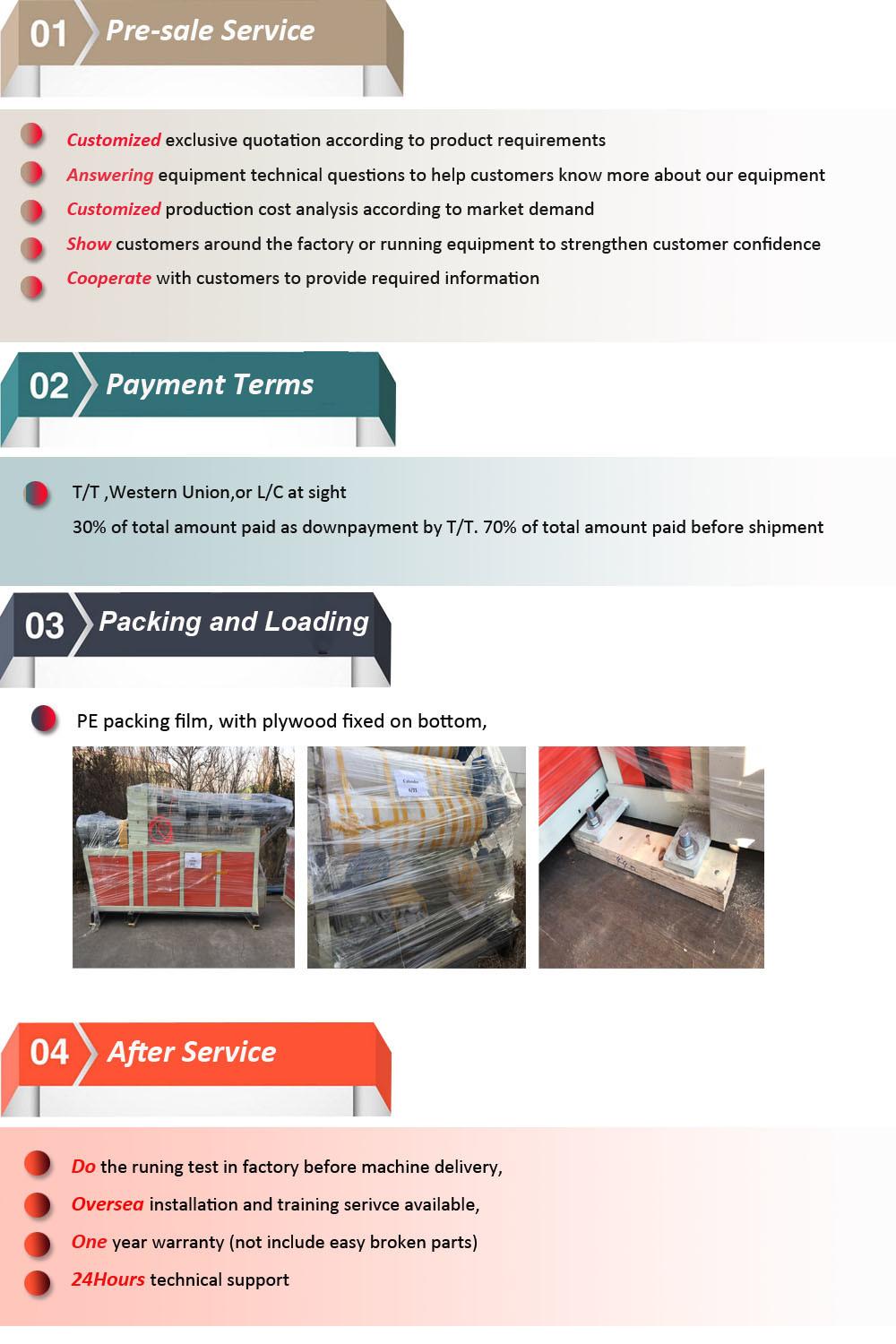

TRADE TERMS

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

- Delivery Time: 40 days after receipt of prepayment.

- Packing Method: Packing film or wooden case

- Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE

- When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

- When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

- If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours.

---Choose Qingdao Suke Machinery ,Choose reliable quality and service---

1. Profession: Qingdao Suke only make plastic extruder since 2002s, extensive experience and professional team ensure our leading position in plastic extruder industry.

2. Quality: The quality of products is footstone of enterprise's constant development, always endeavoring to do still better, quality comes first, developing & innovative is our responsibilities;

3. Delivery: We optimize factory management, and improve production flow so as to shorten production period for you in biggest extent;

4. Cost control: We do best to lower down production cost by our inner management improvement, so as to ensure that our products are competitive enough in the market, and to realize higher performance-price ratio of our products.