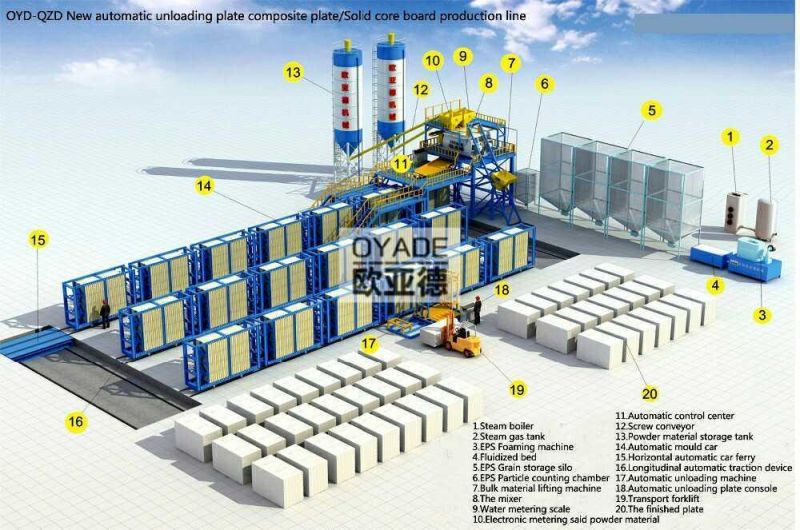

EPS Sandwich Panel Production Line

OYADE (Shandong) Machinery Equipment Co., Ltd.- After-sales Service:Provided After Sales Service

- Warranty:Provided After Sales Service

- Product Type:Construction Material Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

Base Info

- Model NO.:EPS Sandwich Panel Production Line

- Certification:CE

- Condition:New

- Customized:Customized

- Application:Construction Material Machine

- Oyade Factory Site:Jinan City, Shandong Province

- Oyade Factory Area:60000 Sqm

- Oyade Factory History:2008

- Oyade Factory Workers:400 Workers

- Raw Material:Cement Sand Water EPS

- Wall Panel Advantages:Higher Production Capacity

- After Sales Service:Whole Life Time After Sales Service

- Engineer:with 20 Years Experience in Wall Panel

- Main Market:Home and Middle East South East Aisa

- Payment:T,T

- Loading Port:Qingdao

- MOQ:One Set Mold Cars

- Formula:Engineer Will Provide Your Formula

- Production Time:30 Days

- Group:Shandong Oyade Group

- Transport Package:Export Standard Package in 40FT Container

- Specification:based on production capacity

- Trademark:OYADE

- Origin:China

- HS Code:6810999000

- Production Capacity:500 Sets Per Year

Description

Note:

1Others construction rubbish, rice husk, perlite, ties, flyash and so on

2Using normal cement, no steam curing facilities, the temperature is about 20 °C

So for the wall panel's raw material, it is very widely. So this project is higher feasibility in every country.

More details of wall panel machine:

Vertical mold car: It can produce sandwich wall panel and solid wall panel.

Its advantages is bigger productions capacity.

Like wall panel with 100mm thickness, it can produce 36 sheets per mold car.

Horizontal mold cars: It is multifunctional. It can produce all kinds wall panel.

Compared with vertical kind, it can only produce 10 sheets per mold car.

For example, if you want to produce 300 sheets per day/100 mm thickness:

For vertical mold car, you only need to buy 9 sets mold cars

For horizontal mold car, you need to buy 30 sets mold cars. So in this horizontal mold car, your investment in machine is higher than vertical mold car.

Our factory--Shandong Oyade Group

OYD group was established in 2008. she has 5 subsidiaries for producing different kinds of products, eps concrete wall panel production line; mgo board /fiber cement board production line; hollow glass aluminum spacer; Laser cutting machine , etc.

2018-ten years' aniversary meeting

Our proejct in Middle East

Wall panel's installation in Building

External and internal walls, roof and floor

Loading container for customer

FAQ

| 1. | How to curing the wall panel ? |

| Normally curing time is 8-12hours , it can adjust according to your local temperature , also need natural curing around 25-28days before use it . | |

| 2. | Q: How long is the warranty of your equipment? |

| A: 1year ,but we will provide after-sale service the whole life cycle | |

| 3. | Q: Do you supply spare parts? |

| A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year. Other parts we will provide price list in advance . | |

| 4. | Q: Will you provide trainning and formula? |

| A: The training is free of charge , and our engineer will be on duty to train your worker until they know how to produce qualifyed product .Also we will provide you qualified formula | |

| 5. | Q: How will you provide installation&commissioning |

| A: Will provide 2~8persons(adjustable according to the degree of automatic )for installation.Engineers team will go with your project. , besides we only need 15days for commission .in this way can help you save cost on raw material and time . |