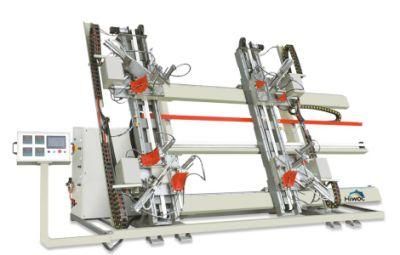

CNC PVC Window Door Welding Machine

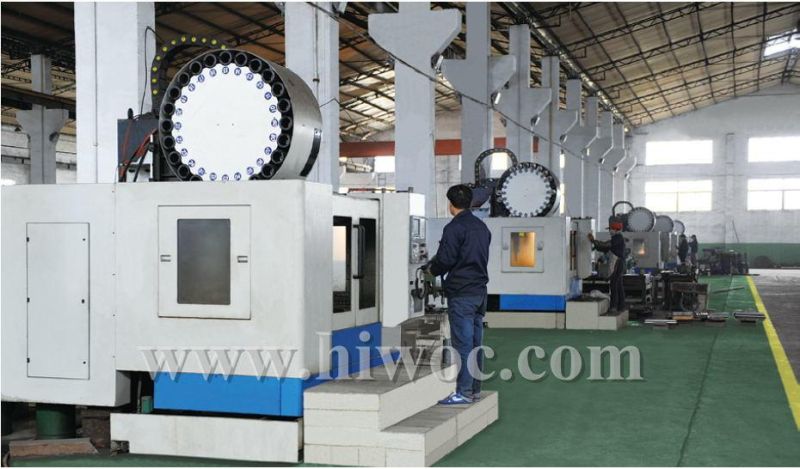

Jinan Hiwoc Group Co., Ltd.- Certification:ISO, CE

- Automatic Grade:Automatic

Base Info

- CNC or Not:CNC

- Voltage:Customized as Customer Need

- Air Pressure:0.5~0.8MPa

- Air Consumption:200L,Min

- Input Voltage:220V 50~60Hz or as Customer Need

- Input Power:4.5kw

- Welding Profile Height:20-120mm

- Welding Width:Max 120mm

- Welding Range:300X3000mm 1800X3000mm

- Overall Size:5500X17000X3000mm

- Color:Cutomized

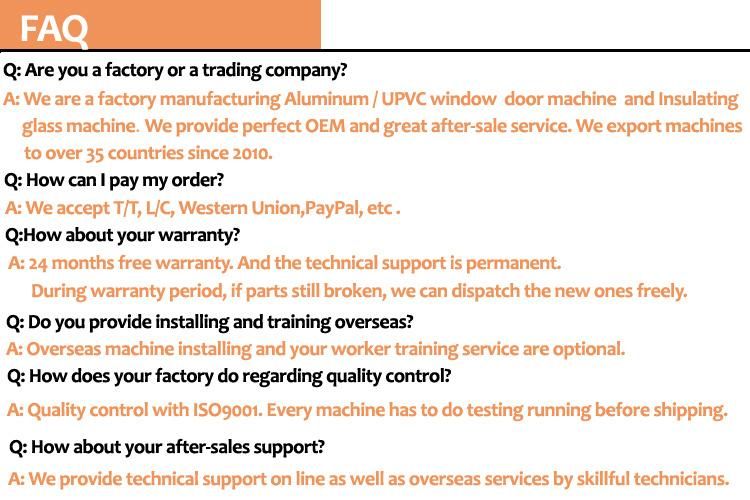

- Warranty Time:2 Years

- Transport Package:Film and Plywood Case

- Specification:5500x17000x3000mm

- Trademark:Hiwoc

- Origin:China

- HS Code:84659200

- Production Capacity:150,Year

Description

Basic Info.

CNC or Not CNC Voltage Customized as Customer Need Air Pressure 0.5~0.8MPa Air Consumption 200L/Min Input Voltage 220V 50~60Hz or as Customer Need Input Power 4.5kw Welding Profile Height 20-120mm Welding Width Max 120mm Welding Range 300X3000mm 1800X3000mm Overall Size 5500X17000X3000mm Color Cutomized Warranty Time 2 Years Transport Package Film and Plywood Case Specification 5500x17000x3000mm Trademark Hiwoc Origin China HS Code 84659200 Production Capacity 150/YearProduct Description

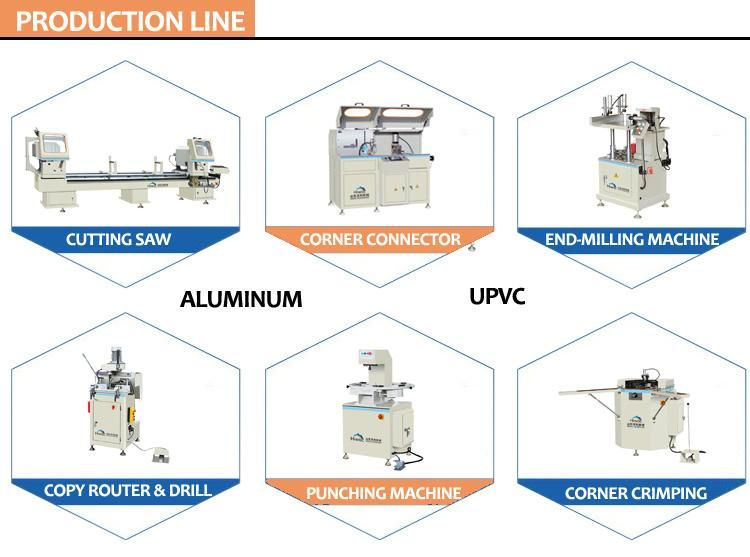

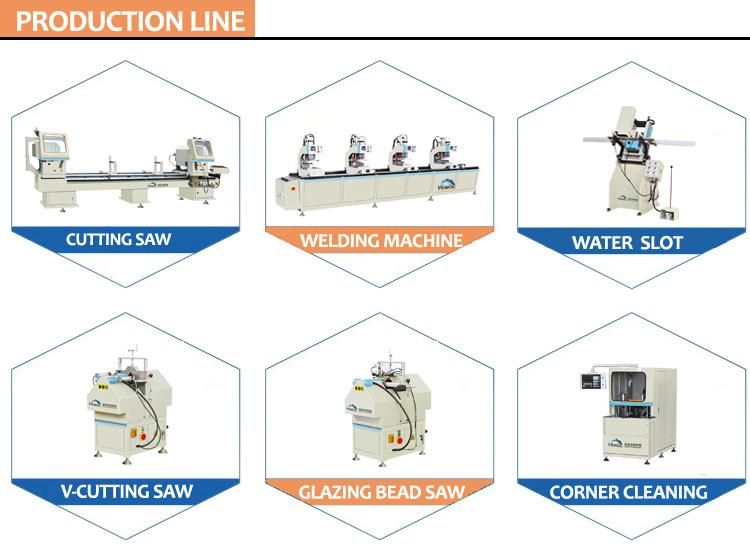

CNC Four Corner Vertical welding machine SHJP4-CNC-3000*1800*120Feature

This machine is the special machine for the welding of plastic door & window. The four heads can finish the rectangle welding with one operation, It has the features of advanced technology, durability, easy operation and high efficiency, etc. It is pneumatic driving with high accuracy and easy maintenance. The pneumatic system uses imported elements with excellent function and longevity. The control part uses the imported programme controller and the driving system uses the imported motors, which ensures the orientation accuracy and durability.1. Automatically for rectangular plastic (UPVC/PVC) door and window frame welding.2. Increased the effective weld height and enhanced rigidity design, high production efficiency.3. Linear bearing motion pair, high precision equipment, stable technical performance.4. The unique positioning mechanism and a clamping device ensure the welding size precision and stability of shape position precision.5. Adopted the three coated craft route, with profiles positioning and clamping function, effectively ensured the welding finished product size precision and flatness shape and position accuracy6. Imported Japan Mitsubishi CNC control system

| Parameter | |

| Air Pressure | 0.5~0.8MPa |

| Air consumption | 200L/min |

| Input Voltage | 220V 50~60Hz or As Customer need |

| Input Power | 4.5Kw |

| Welding profile height | 20-120mm |

| Welding Width | Max 120mm |

| Welding range | 300x3000mm 1800x3000mm |

| Overall size | 5500×17000×3000mm |

| Weight | 3800kg |

| Main accessory | |

| Control system | Mitsubishi |

| PLC | Taiwan Delta |

| Solenoid valve | Airtec |

| Cylinder | Huatong |

| Motor | Anhui Sanyang (Best Chinese Motor Brand) |

| Air Filter Device | STNC |

| Electrical Button and Switcher | Schneider |

| AC Contactor and Circuit Breaker | Schneider |

| Temperature Controller | Japan Omron |

| Standard accessory | |

| Heat plate | 4 pcs |

| Teflon cloth | several |

| Complete tooling | 1set |

| Certificate | 1pc |

| Operation Manual | 1pc |