Paper Faced Gypsum Board Production Line with German Technology

OYADE (Shandong) Machinery Equipment Co., Ltd.- Warranty:12 Months

- Product Type:Pleasterboard Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO

Base Info

- Model NO.:YR-G6100

- Condition:New

- Customized:Customized

- Application:Produce Gypsum Board

- Dryer Technology:Heat Transfer Oil; Hot Air

- Fuel:Coal; Diesel; Natural Gas; Heavy Oil

- Gypsum Board Thickness:6-22mm

- Capacity:2million ~ 30 Million

- Control System:PLC Center Control

- Installation:Guide by Our Engineer

- After Sale Service:for Whole Using Life

- Voltage:380V 50Hz, Adjust According to Your Country

- Workers:10-15person

- Transport Package:Use Steel Wire Rope to Fix in The Container,

- Specification:2million ~ 30 million

- Trademark:YR

- Origin:Shandong, China

- HS Code:8474809010

- Production Capacity:20sets Per Year

Description

Basic Info.

Model NO. YR-G6100 Condition New Customized Customized Application Produce Gypsum Board Dryer Technology Heat Transfer Oil; Hot Air Fuel Coal; Diesel; Natural Gas; Heavy Oil Gypsum Board Thickness 6-22mm Capacity 2million ~ 30 Million Control System PLC Center Control Installation Guide by Our Engineer After Sale Service for Whole Using Life Voltage 380V 50Hz, Adjust According to Your Country Workers 10-15person Transport Package Use Steel Wire Rope to Fix in The Container, Specification 2million ~ 30 million Trademark YR Origin Shandong, China HS Code 8474809010 Production Capacity 20sets Per YearProduct Description

paper faced gypsum board machinery manufacturersSpecial serviceWe provide installation/improvement/commissioning/update for small line !

Dears, if you have an production line can't work well, can't operate, your supplier didn't install/testing for you , or you want to expand capacity, or you want to change fuel, or you want to update......we provide professional team for such special service!!!

Characteristics of the equipment

Development and application of the new high-speed mixer. High speed strring aims at shortening the gypsum slurry time (mix average within 10 seconds), helps to make full use of gypsum slurry liquidity, so don't have to add the retarder. Application of reverse discharging speeds up the pulp out of discharge, and makes gypsum fully flow in the mold. The appearance size of gypsum block has a high precision, ensuring the product quality and accuracy.

Easy to form a complete set. Except the special parts for the production line, the other parts can use the Chinese standard equipment. The quality is controlled in accordance with the ISO9001 strictly. Key electronic components adopt international famous company high quality products, guaranteeing to provide customers high quality, reliable operation of equipment.

The scale of production and the area of the plant is moderate and match the automation and the mechanization of the production line, which is easy to manage.

Less investment and mature production technology. The production cycle is short and easy to guarantee the quality of the product.

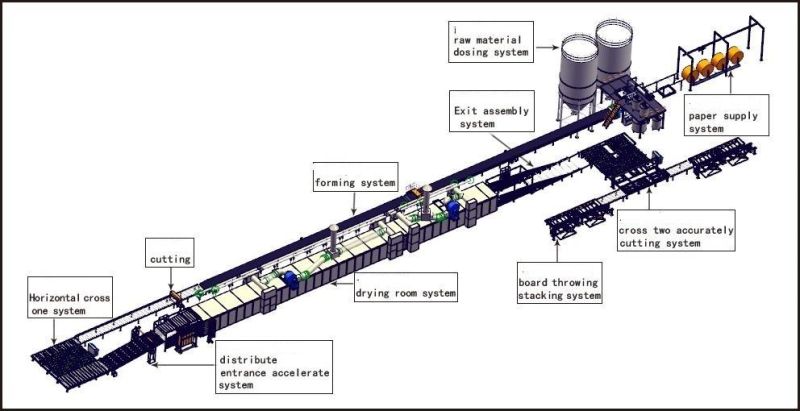

Layout of paper faced gypsum board machinery

Equipment advantages-paper faced gypsum board machinery

After years of research and development, our manufacturing is stable and reliable, accurate, saving energy and reducing consumption, and the advantages of low noise, we have 8 patented gypsum board making equipment technologies:

1. Fine workmanship, high precision, reliable quality, beautiful appearance.

2. Accurate dosing raw material, foam foam standing is our patent, produce the board of light weight, good toughness and cost savings,

3. The cutting machine uses dual-serve motor, only1 mm gap between cutting saw, saving cost .

4. We adopt the hot air circulation, drying room temperature is uniform, the board has high strength and is not fragile.

5. High electrical automation degree, low failure rate, less workers.

Manufacture strength-paper faced gypsum board machinery

As a professional gypsum board making equipment manufacturer , we have a vertical processing center, boring machines, milling machine, drilling machines, planers, argon welders and so on. Good processing equipment makeshift good machines.

Fine workmanship High precision

Reliable quality Beautiful appearance

Quality show-paper faced gypsum board machinery

FAQ

| Q | How many projects have you installed? |

| A | we have installed over 100projects in domestic and abroad. |

| Q | How many years experience do you have in mgo field? |

| A | Our general engineer has around 20years experience; all others have over 10years experience. |

| Q: | Do you supply spare parts? |

| A: | Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year. |

| Q: | Will you provide trainning? |

| A: | The training is free of charge , and our engineer will be on duty to train your worker. |

| Q: | How will you provide installation&commissioning? |

| A: | Will provide 2~4persons(adjustable according to the degree of automatic )for installation. |

Company advantages & Contact

Rich experience

We have rich experience in gypsum board making equipment field. Our general engineer has over 20years experience, other main engineers all have over 10years experience, proficient in the newest gypsum board manufacturing plant design and manufacturing. With over 100 projects in domestic and abroad markets, we can ensure you a successful project.

Professional teamwork

1.Sales team: 24hours online for you

2. Designing team: design the best layout for you

3. Manufacturing team: promise the best quality with high precision

4. Installation & commissioning team: finish the installation and testing of whole line

5. Process team: promise you the qualfied formula.

Excellent Service

Our company provides full life-cycle value services for gypsum board making equipment design, cost accounting, installation and operation, equipment maintenance and the whole life cycle technical support

Contact me

Eva

Mobile : +8617806182338

http://yurui2018.en.made-in-china.com