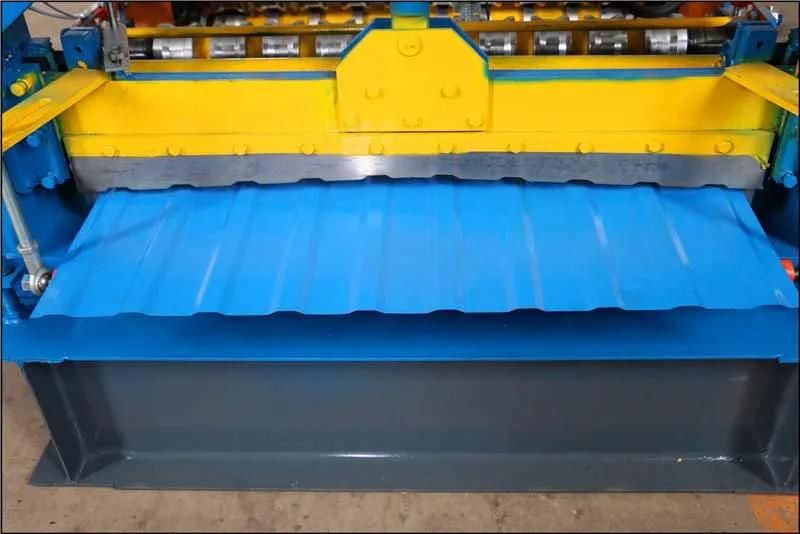

Dx 1050 Wall and Roof Pane Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Tile Type:Colored Steel

- Certification:CE, ISO, ISO9001: 2000, CE, SGS

- Condition:New

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Machinery

Base Info

- Model NO.:1050

- Machine Name:Wall and Roof Roll Forming Machine

- Effective:Easy Operation

- Type:Concrete Iron Strengthen Machinery

- Method:Rolling Machine

- Processing:Rolling Machine

- Brick Raw Material:Steel

- Automation:Automatic

- Tolerance:1.0mm

- Name:Wall and Roof Roll Forming Machine

- Transport Package:Nude Package

- Specification:CE BV ISO

- Trademark:DIXIN

- Origin:Cangzhou City, Hebei Province, China

- HS Code:84552210

- Production Capacity:20sets,Per Month

Description

Basic Info.

Model NO. 1050 Machine Name Wall and Roof Roll Forming Machine Effective Easy Operation Type Concrete Iron Strengthen Machinery Method Rolling Machine Processing Rolling Machine Brick Raw Material Steel Automation Automatic Tolerance 1.0mm Name Wall and Roof Roll Forming Machine Transport Package Nude Package Specification CE BV ISO Trademark DIXIN Origin Cangzhou City, Hebei Province, China HS Code 84552210 Production Capacity 20sets/Per MonthProduct Description

Dx 1050 Wall and Roof Pane Roll Forming making Machine

1. Technique parameters

(1) Processing material: Aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Effective width: 1050mm

(4) Feeding width: 1250mm

(5) Main motor power: 4 kw

(6) Pump power: 4 kw

(7) Shaft diameter: 75mm

(8) Forming steps: 15steps

(9) Roller material: 45# forged steel, with hard chrome plating

(10) Main frame: 300H steel

(11) Medium plate thickness: 14mm

(12) Control systerm: PLC computer control with inverter

(13) Power supply: 380V, 3 Phase, 50Hz

(14) 0veral sized: 6500mm*1500mm*1500mm

(15)Total weight: 2.7 tons

2. Work flow

Manual decoiler- Roll forming machine- PLC control- Hydraulic system - Post cut- Stacking

3. Specific description

(1) Manual decoiler

Un-powered, single head, max capacity: 5000kg

(2) hydraulic pump station

It is controlled by gear wheel oil pump, after filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutting machine to begin the cutting job.

(3) Computer control cabinet

It adopts TaiDa PLC to control, the target sheet length is adjustable.

Computed mode has two modes: Automatic and manual.

Touch screen.

(4) Output table

It is used to load the finished sheet. This kind is convenient for shipment.

(5) Spare parts

4. Payment term

TT, you should pay 30% as the deposit on the order day, then pay 70% before delivery when you inspect goods well in factory or by video

5. Warranty

12 months, and lifelong technical support service

6. Installation

If you need, we will send one technician to your factory to install & testing the machine. You should assist the technician to get Visa and pay for flight tickets and local accommodation, and pay 80 USD/day for salary.

7. Package

Standard export package, water-proof package, covered with plastic film

| No. | Name | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

Certificate CE, ISO9001

FAQ

1.Q: How can I contact you?

A: You can talk to me anytime. Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you.

2. Do you have after sales support?

A:Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3.Q: How to visit our company?

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

4.Q: How many years since you have been in this field?

A: Our company has been producing roll forming machines for almost 20years.We have rich experience for manufacturing and designing the machine.

5.Q. What can you do if the machine broken?

A:Our machine's warranty period is 12months, if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself. if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

6.Q:How long the machine could be made?

A:Normally speaking, machine could be made within 30 working days. If you need machines in a hurry, we can make it for you less than a month.

6.Q:If our country's voltage is different from yours, how to solve that?

A:The usual voltage is 380v,220v,415v. If yours are not one of them, we will design the electric motor to suit your voltage.