Colour Coated Roofing Sheet Making Machine

Tianjin Haixing Imp. & Exp. Co., Ltd.- After-sales Service:Video Technical Support

- Warranty:2years

- Tile Type:Colored Steel

- Certification:CE, ISO

- Condition:New

- Customized:Customized

Base Info

- Model NO.:HX840+HX900

- Usage:Roof, Wall

- Transmission Method:Hydraulic Pressure

- Raw Material:PPGI

- Usag:Steel Construction

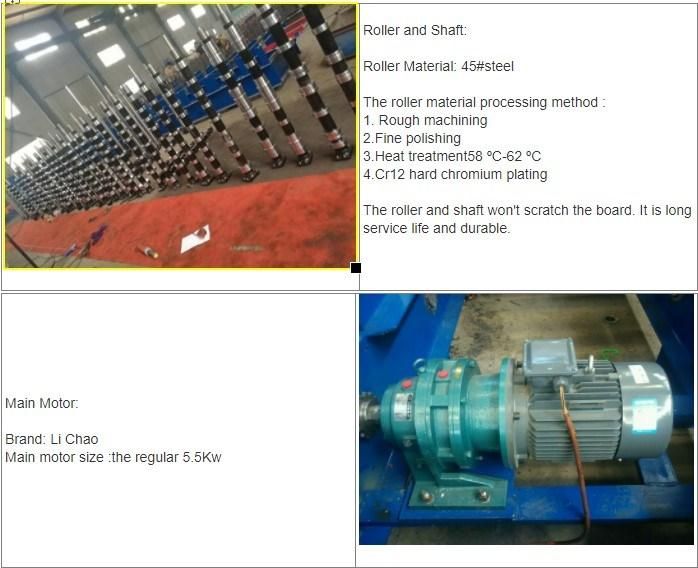

- Roller Material:45#Steel Chrome Plated

- Shaft Material:70mm,75mm(Depend on Different Design)

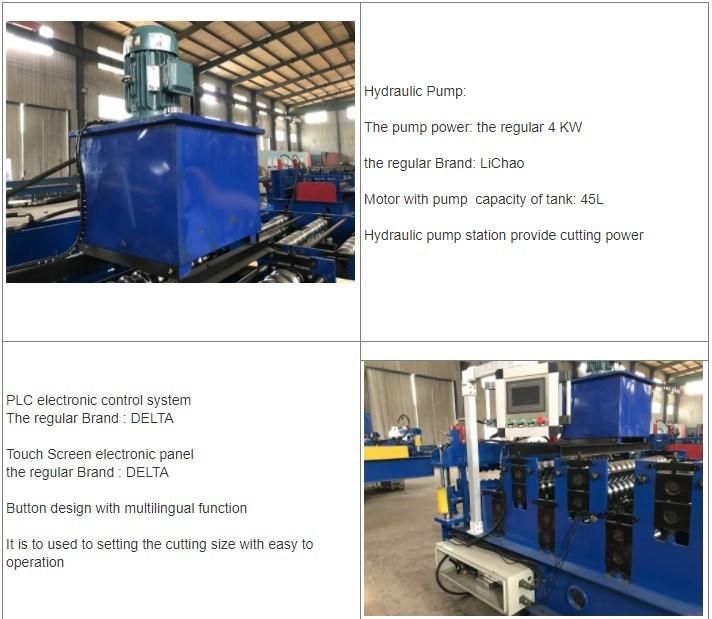

- Control System:PLC

- Color:Blue

- Thickness:0.3--0.8mm

- Application:Construction Panel

- Main Frame:350h Steel

- Operate Style:Delta

- Lanuage:Chinese,English

- Motor Brand:China Famous Brand

- Function:Color Roof Tile

- Cutting System:Automatic Hydyaulic Cutting

- Profiles:One Profile

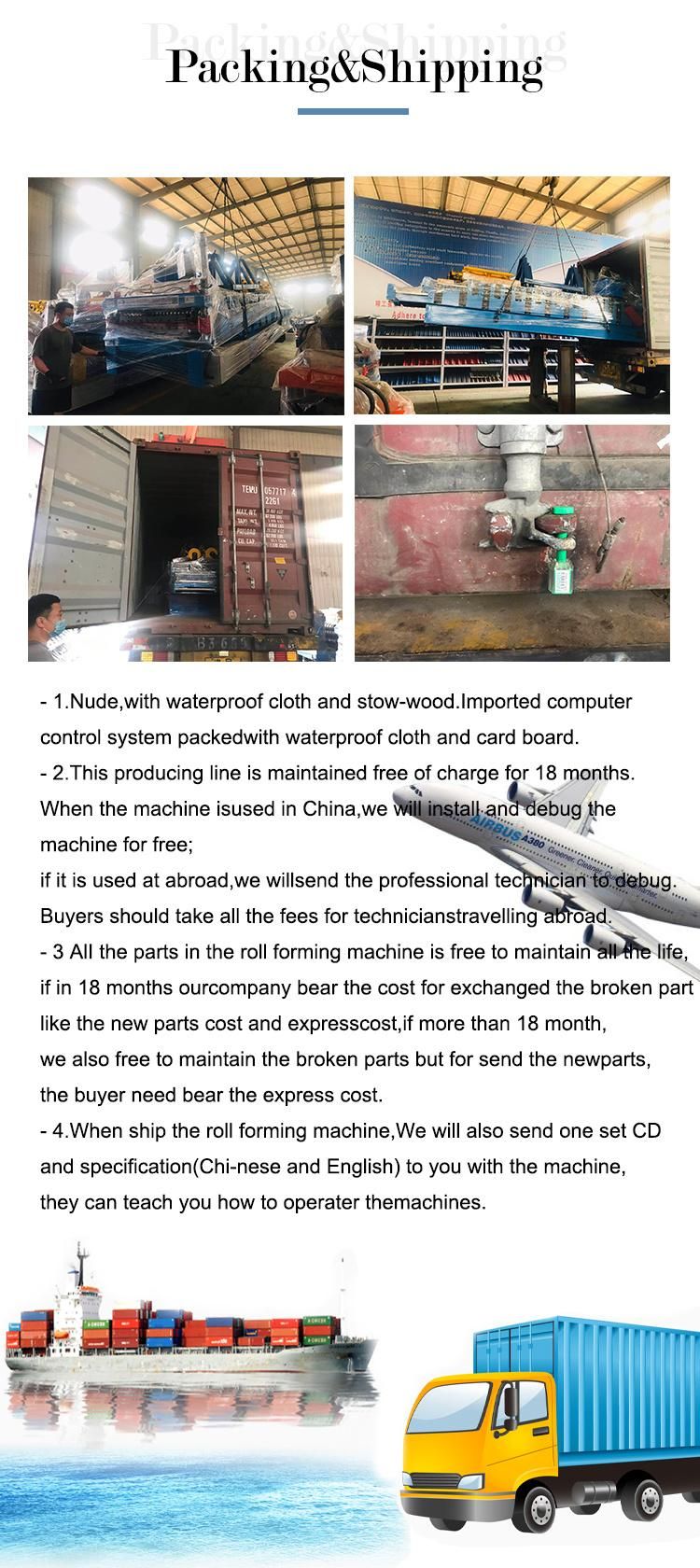

- Transport Package:Container

- Specification:20CBM

- Trademark:HX

- Origin:China

- HS Code:84552210

- Production Capacity:200set,Month

Description

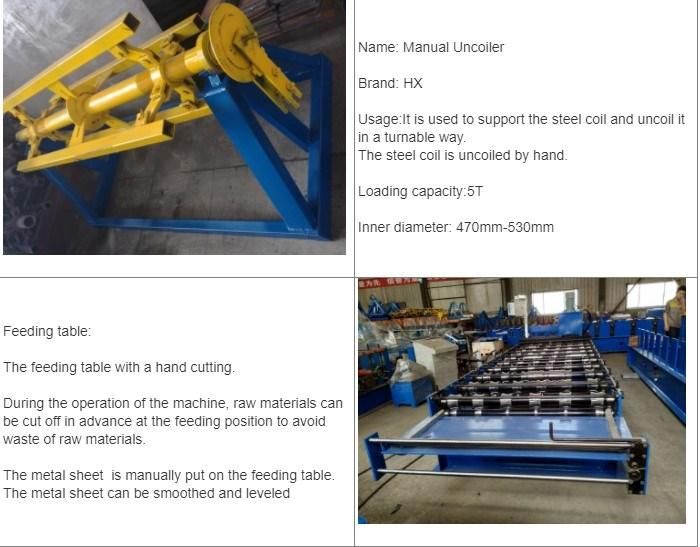

Hydraulic pump station : 4KW Regular Brand: LI CHAO

Type: Double guide pillar Hydraulic Cutting

Blade: Cr12 Mov HRC 58-62

Colour Coated Roofing Sheet Making Machine Advantage:

1. Famous Brand, quality is guaranteed.

2. Full Automatic Computer Control make easy to operation.

3. Machine roller and shaft is produced by exact demands and control . The roller material processing method is by CR12 MOV heat treatment 58ºC-62ºC . The product quality is durable and long service life .

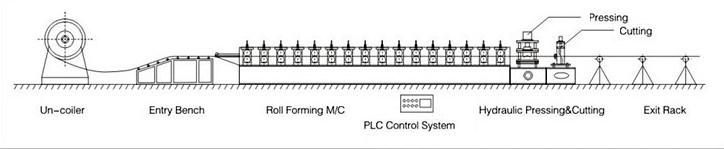

Working Flow and Main parts of Colour Coated Roofing Sheet Making Machine:

Our services:

Advantage of the service:

1. Provides engineering drawing design services

2.Provide machine customization service

3.Remote video service

4.Engineer on-the- spot installation service

5. Help customers booking shipping service

6.Help customers purchase raw materials service

After-sales service:

1.Payment Term: 30% paid by T/T as down payment, the rest 70% after inspection by buyer in seller's factory while before delivery.

2.Delivery Time: We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.After sale Service: We could send technician to your country to install machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.Warranty: 2years

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.