Floor Deck Roll Forming Machine/Construction Equipment Floor Deck Tile Making Roll Forming Machine/ Colored Steel/Customized

Cangzhou Zhongheng Machine Manufacture Co., Ltd.- After-sales Service:2 Years

- Warranty:2 Years

- Tile Type:Colored Steel

- Certification:CE

- Condition:New

- Customized:Customized

Base Info

- Usage:Roof, Wall

- Transmission Method:Electric

- Feature:Ibr Trapezoidal Galvalume Metal Steel Roofing Cold

- Suitable Material:PPGI Gi

- Thickness:0.3-0.8mm

- Width:1250mm as Custom Profile

- Voltage:380V

- Speed:30m,Min

- Rollers:45# Steel as Customer Require

- Motor:5.5kw

- Control:PLC Delta

- Cutting:Hydraulic , Electric

- Key Selling Points:Easy to Operate

- Cutting Blade:Cr12 MOV

- Delivery Time:40 Days

- Transport Package:Plastic File

- Specification:7.8X1.5X1.7M

- Trademark:ZH

- Origin:Hebei, China

- HS Code:8455221000

- Production Capacity:20 Sets Per Month

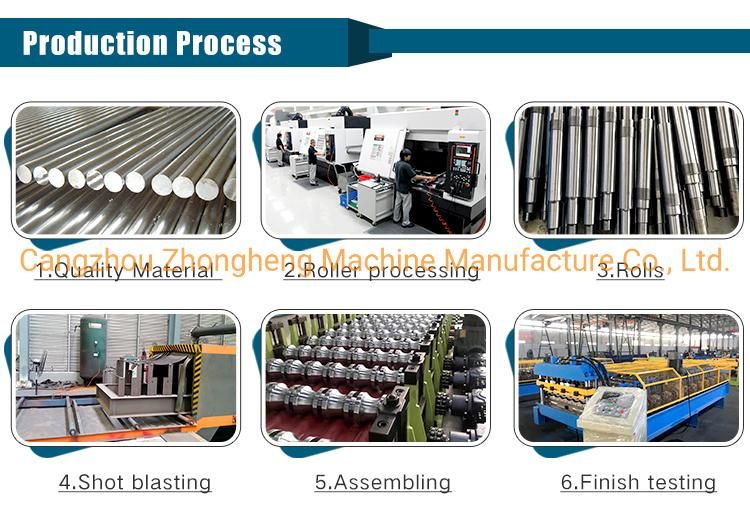

Description

Basic Info.

Usage Roof, Wall Transmission Method Electric Feature Ibr Trapezoidal Galvalume Metal Steel Roofing Cold Suitable Material PPGI Gi Thickness 0.3-0.8mm Width 1250mm as Custom Profile Voltage 380V Speed 30m/Min Rollers 45# Steel as Customer Require Motor 5.5kw Control PLC Delta Cutting Hydraulic / Electric Key Selling Points Easy to Operate Cutting Blade Cr12 MOV Delivery Time 40 Days Transport Package Plastic File Specification 7.8X1.5X1.7M Trademark ZH Origin Hebei, China HS Code 8455221000 Production Capacity 20 Sets Per MonthProduct Description

Metal Steel Roofing Cold Roll Forming Machine

Since it was first introduced to South Africa in 1958, IBR has enjoyed great popularity for use as side cladding or roofing material in commercial, industrial and residential buildings. IBR got its name from the abbreviation of "Inverted Box Rib", which has become a household name in the South African building industry. Actually, IBR is a square fluted profile with an effective covering width of 686 mm or 890mm. ZHONGHENG have several kinds of design IBR Sheet Roll Forming Machine for IBR sheeting. and all are customized. Our IBR Sheet Machine is able to form G550 Mpa and thickness up to 0.8mm . And also Corrugated Sheets Roll Forming Machine is designed for South African Customer.

Ibr Roofing Sheet Roll Forming Machine for Processing Galvanized Steel Description

Roll Forming Machine for Processing Galvanized Steel Parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 4.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer`s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 20mm/18mm/16mm/14mm/12mm |

| Drive mode | Chain Drice//Gear Drive |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 18 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw, 4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.3-0.6mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12m/min |

| Package of machine | Waterproofing membrane, standard export packing |

Detailed Photos

Technical Data:

1. Manual Decoiler

Decoiler Type: Manual Decoiler

Weight Capacity Of Decoiler: 3 Ton

Inner Diameter. Φ460-520mm

Outer Diameter. Φ1400mm

2. Roll Forming system

Axis Diameter:70 mm

Forming Roller stand: 18Groups

Main Axis material: First grade 45# steel, heated and quenched

Roller material: First grade 45# steel, with hard chrome 0.05mm, Quenched and heated process

Drive Type: 1" Chain of transmission

Chain material: 45#steel, HRC45-50

Machine Frame stand: Welded structural steel

Main motor Power: 5.5 KW

3. Cutting Device (include 2 size)

Cutting type: Hydraulic cutting

Hydraulic pump station power: 4 KW

Hydraulic pressure: 12Mpa

Hydraulic Blade and cutter material: Cr12, quenching process 58-62

Cutting length tolerance: 10M+/- 2.0 mm

4. Electrical System

Voltage: 380V, 3 Phase 50Hz

PLC Electrical control system: PANASONIC

Length Controller: Encoder Frequency Control System

Operation: Touch Screen

Transducer: Delta

5. Runout Table:

Non-power type

Quantity:2

Packing and Shipping

1.Roll Forming Machine for Processing Galvanized Steel need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Company Introduction

FAQ

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warranty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .

Contact of Sunny

More information please send inquiry to us , you will get reply within 12 hours !