High Precision Bright Annealing Coil Stainless Steel Pipe Making Machine

Guangdong Shunde Seko Machinery Technology Co., Ltd.- Pipe Material:Stainless Steel

- Condition:New

- Customized:Customized

- Theory:Inverter

- Application:Industry

- Type:Pipe Production Line

Base Info

- Model NO.:SZG-30,40,50,60,80,100,120

- Product Name:Stainless Steel Coil Pipe Machine Making Machine

- O.D. Range:6-325 mm

- Thickness:0.38-10.0

- Control Type:PLC

- Production Speed:1-7 M,Min

- Certification:ISO9001

- Power(W):00

- Voltage:380V 50Hz

- Power Supply:415V,3pH

- Dimension(L*W*H):20.0m

- Weight:5-15t

- Color:Customized

- Warranty:1 Year

- Lead Time:30-60 Days

- After-Sales Service:Engineers Service Machinery Overseas Available

- Transport Package:Waterproof Film and Pallets

- Specification:Iron

- Trademark:SEKO

- Origin:China

- HS Code:8455102000

- Production Capacity:30 Sets Per Year

Description

Basic Info.

Model NO. SZG-30/40/50/60/80/100/120 Product Name Stainless Steel Coil Pipe Machine Making Machine O.D. Range 6-325 mm Thickness 0.38-10.0 Control Type PLC Production Speed 1-7 M/Min Certification ISO9001 Power(W) 00 Voltage 380V 50Hz Power Supply 415V/3pH Dimension(L*W*H) 20.0m Weight 5-15t Color Customized Warranty 1 Year Lead Time 30-60 Days After-Sales Service Engineers Service Machinery Overseas Available Transport Package Waterproof Film and Pallets Specification Iron Trademark SEKO Origin China HS Code 8455102000 Production Capacity 30 Sets Per YearProduct Description

High Precision Bright Annealing Coil Stainless Steel Pipe Making MachineProduct Details

| Type | Material | Welding type | O.D. (mm) | Thickness (mm) | Motor Power (KW) | Size(L*W*H)(m) |

| SZG-30 | SST | TIG | 6-16 | 0.4-1.5 | 5.5 | Customized |

| SZG-40 | SST | TIG | 16-50.8 | 0.5-2.5 | 7.5 | Customized |

| SZG-50 | SST | TIG | 25.4-76 | 0.5-3.0 | 11 | Customized |

| SZG-60 | SST | TIG | 50.8-114 | 1.0-4.0 | 15 | Customized |

| SZG-80 | SST | TIG | 89-168 | 1.0-5.0 | 18.5 | Customized |

| SZG-100 | SST | TIG | 114-219 | 2.0-8.0 | 30 | Customized |

| SZG-120 | SST | TIG | 168-325 | 3.0-10.0 | 37 | Customized |

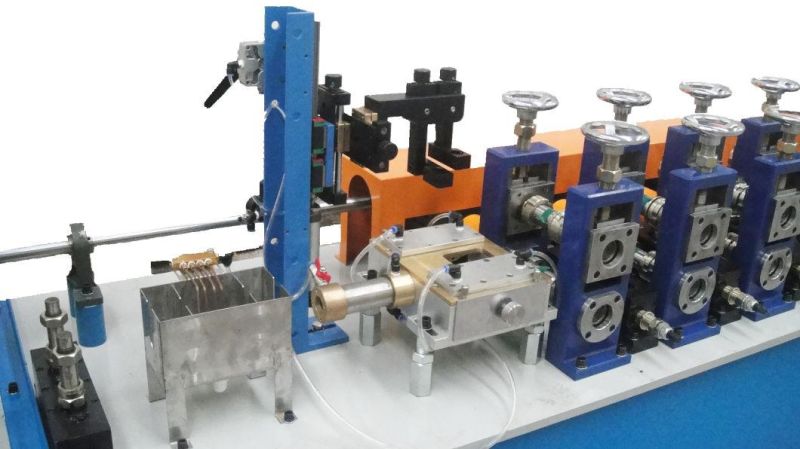

Product Photos

Uncoiler

Basic Composition of Forming Section

Welding Section

On-line Bright Annealing Furnace

Final Sizing

Our Advantages

Efficiency

1. Using electromagnetic control system to correct the arc trajectory, improving working speed at least 25% higher and guaranteeing the welding seam quality. The highest speed could reach up to 12 m/min for the TIG welding with excellent welding seam.

2. It not only speeds up the efficiency, but also save the consumption and factory's room, with continuous, single tube and on-line heat processing. The minimun processed O.D could be 10-12.7mm.

Automation

Labor costs saving. One person could monitor 2 production lines in the meanwhile. Our self developed PLC control system could cordinate every section automatically. With HMI touching screen, you could use it easily.

Anti-corrossion

High quality rollers are made of material SKD11, with vacumm gas quenching. Hardness reaches up to 64-66, with CNC high precision processing.

Accuracy

Precise CNC processing could ensure the smooth surface with less scratch happenning when forming. Accurate size could controle the tolerance at the range of ±0.5-1.0 mm.

Visible design of micro adjusting device of roller's lifting, making roller replacement higher operability.

Usage

SEKO Machinery high precision bright annealing coil stainless steel pipe making machine specializes in industrial usage, like HVAC pipe fittings, sanitary tubes, water pipes, valve pipe fittings, petrochemical pipes, chemical industry, medicine industry, wine-making industry, petroleum industry, food industry, automobile industry, paper making industry, air-condition making industry and so on. Products dealed with our tube mill could reach ASTM, DIN, ISO, GB and JIS standard.Our heat exchanger tubing stainless steel coil pipe production line use IGBT and digital control system. It could control the electricity consumption precisely, in order to lower the costs.

About SEKO

Guangdong Shunde Seko Machinery Co., Ltd. is a manufacturer, specializing in industrial stainless steel pipe making machine, on-line bright annealing machine, weld bead rolling machine, steel pipe polishing machine and other tube mill components. With more than 20-year experience, we integrates designa, development, manufacture, after-sale service and other supporting service. Many top manufacturers like Jiuli, Wujin, Sanhua, USA Plymouth, India Pennar and etc., have become our partner. Our items are exported to Dubai, Russia, India, Thailand, Pakistan, Vietnam and ect..

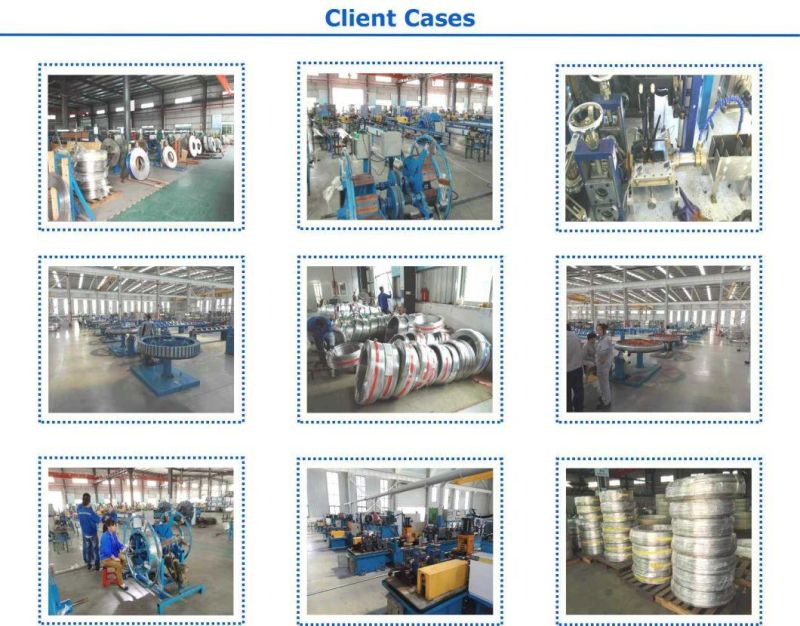

Our Partner

FAQ

1. Which countries your products are exported to?

Our pipe production lines are sold all over the world and with related certifications.

2.How about the warranty?

All our pipe production lines have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your pipe production lines?

Usually speaking, engineers will be sent to your factory to help to install and adjust the machines. We also have paper installation instructions and videos, teaching you till you command it.

4. Which export port you use?

Any China ports. Commonly, we will use Shenzhen port. But it can be appointed as you like.

5. How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 40% deposit, 60% before shipment (we will shoot total delivering process for customer's confirmation) and the related papers. You can pay by T/T,L/C, Western Union or other ways.

The machine delivery time is within 45-90 days.

6.Is your goods with ISO9001 or CE certificate ?

Yes, all our pipe production lines has ISO certificate. All machines are high quality goods.

7.What is your nature of your company:dealer or factory ?

We are manufacturer of pipe production lines with a big factory ,warmly welcome to visit our factory and contact us.

Contact Us For More About SEKO Stainless Steel Pipe Production Line