Production Machine CNC Four Corner Crimping Machine

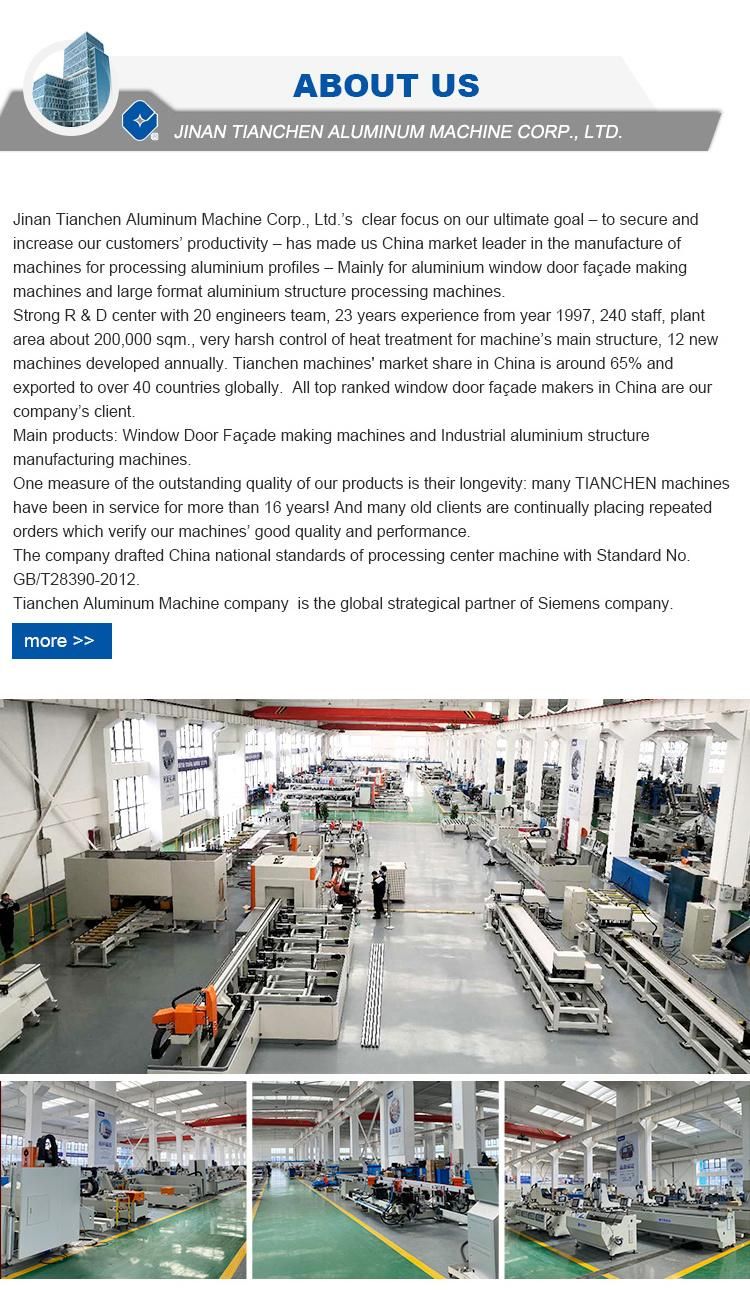

Jinan Tianchen Smart Machine Co., Ltd.- Condition:New

- Certification:ISO

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:380V

- Control System:Schneider

Base Info

- Model NO.:LM4XA-CNC-100x2200x3000

- Maximum Workable Frame Size:2200X3000mm

- Minimum Workable Frame Size:700X450mm

- Productivity:45 Seconds One Frame Can Be Done

- Crimping Tool Numbers:8

- Net Weight:About 3 Tons

- Application Field:Making Windows and Doors

- Crimping Accuracy:High

- Transport Package:by Container

- Specification:40FRx1+20GPx1

- Trademark:Tianchen

- Origin:Jinan, Shandong, China

- HS Code:8461409000

- Production Capacity:20 Sets Per Month

Description

Basic Info.

Model NO. LM4XA-CNC-100x2200x3000 Maximum Workable Frame Size 2200X3000mm Minimum Workable Frame Size 700X450mm Productivity 45 Seconds One Frame Can Be Done Crimping Tool Numbers 8 Net Weight About 3 Tons Application Field Making Windows and Doors Crimping Accuracy High Transport Package by Container Specification 40FRx1+20GPx1 Trademark Tianchen Origin Jinan, Shandong, China HS Code 8461409000 Production Capacity 20 Sets Per MonthProduct Description

CNC Four Head Corner Crimping Production LineModel LM4XA-CNC-100*2200*3000

Main Technical Specifications:☆ Motor power of assembly station: 0.55kW

☆ Motor power of transmission station: 6×0.55kW

☆ Input voltage: 380V 50Hz or as per customized value

☆ Air pressure: 0.6-0.8MPa

☆ Max frame dimension: 2200×3000mm

☆ Min frame dimension: 700×450mm

☆ Rating oil pressure: 15MPa

☆ Capability of oil tank: 40L

☆ Diagonal line length error of finished product: ≤1mm

☆ Connection seam error: ≤0.15mm

☆ Contour dimension: About 16000×5000×1810mm

☆ Net Weight: About 3000kgMain Outsourced Components List:

| Item | Brand name |

| Servo System | Schneider |

| Air Pneumatic components | SMC and Airtac |

| PLC | Schneider |

| Low voltage electrical components | Siemens/Schneider |

| Industrial Computer | HAIDE Combined computer |

| Rack | YYC |

| Guide Rail | Hiwin |

| Ball Screw | PMI |

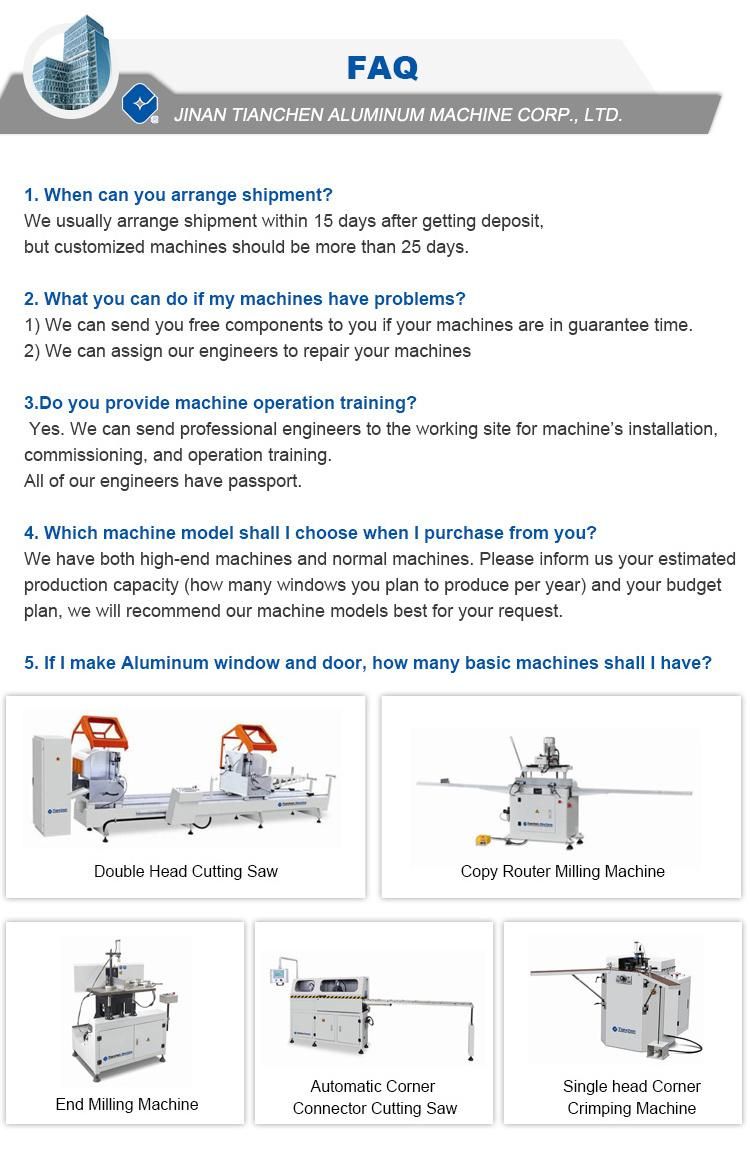

Machine FeaturesThe work efficiency is very high, in average it takes just about 45 seconds to finish the 4 corner crimping for one window. Namely, one window's 4 corner crimping can be done in 45 seconds only. Approximately in one shift (8 hours) 550 window frames/ sashes can be done.

Crimping tool can be especially customized as per aluminium profile's section structure, which can greatly save the time of adjusting crimping tools, then highly increase the production efficiency.

The 4 corners' crimping all are done at same height level, which can well assure very good flatness of the window. Compared the vertical corner crimping machine's structure, obviously this machine can get much better window flatness.

High performance Schneider control system ensures machine's work stability and reliability.

High performance Schneider control system ensures machine's work stability and reliability.

The operation of the machine is very easy, the operator just needs to load the material from one end and unload the material from the other end, it's convenient and not so tiring for the operator compared with other corner crimping machine.