Hot Selling Qtj4-40 Concrete Cement Hollow Solid Pavement Interlocking Brick Making Machine for Sale

Shandong Xinming International Trade Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Semiautomatic

- Type:Vibration Molding

- Pallet Size:850*550*20mm

- Mold Period:40 Seconds

Base Info

- Model NO.:QTJ4-40

- Power Type:Electric Motor

- Total Weight:2000kgs

- Color:Optional

- Vibration Force:20kn

- Electricity:380V,220V(Adjustable)

- Host Machine Power:8.8kw

- Block Type:Hollow, Paver, Solid, Curbstone Block etc

- Block Material:Sand, Cement, Cinder, Stone etc

- Upper Vibrator:2.2kw

- Nether Vibrator:4.4kw

- Labor:2-3 Workers

- Mixer Model:Jq350 Mixer

- Standard Hollow Block:400*200*200mm

- Transport Package:Nude in Container,LCL

- Specification:1350*1460*1800mm

- Trademark:Xinming

- Origin:China

- HS Code:8474802000

- Production Capacity:500PCS,Month

Description

1. Maintance: QTJ4-40 hollow solid block making machine is easy in maintance. please clean the mixer and mold after everyday work and fasten screws and add lubrication oil to moving parts before every day work.

2. Install Service: We will ship machine in whole one. you only connect elecctricity line with block machine, the machine can work. the manual and installtion video is avaible.

3. Guarantee Time: One year. we will supply free accessories with machine for one year use. and technical service and spare parts are avaible in all time.

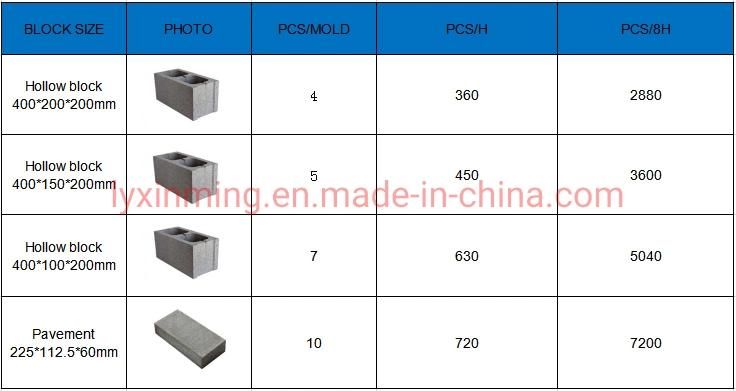

Production Capacity

QTJ4-40 Concrete Block Making Machine is multipurpose,especisally,the mold is changeable.It is designed to match the various coustomer requirement s,such as concrete hollow block,paver brick,soild block,curbstone etc.

Packing&Shipping

After we finish customers' block machine, we will pack the machine by plywood, and deliver to customers by best and fastest way.

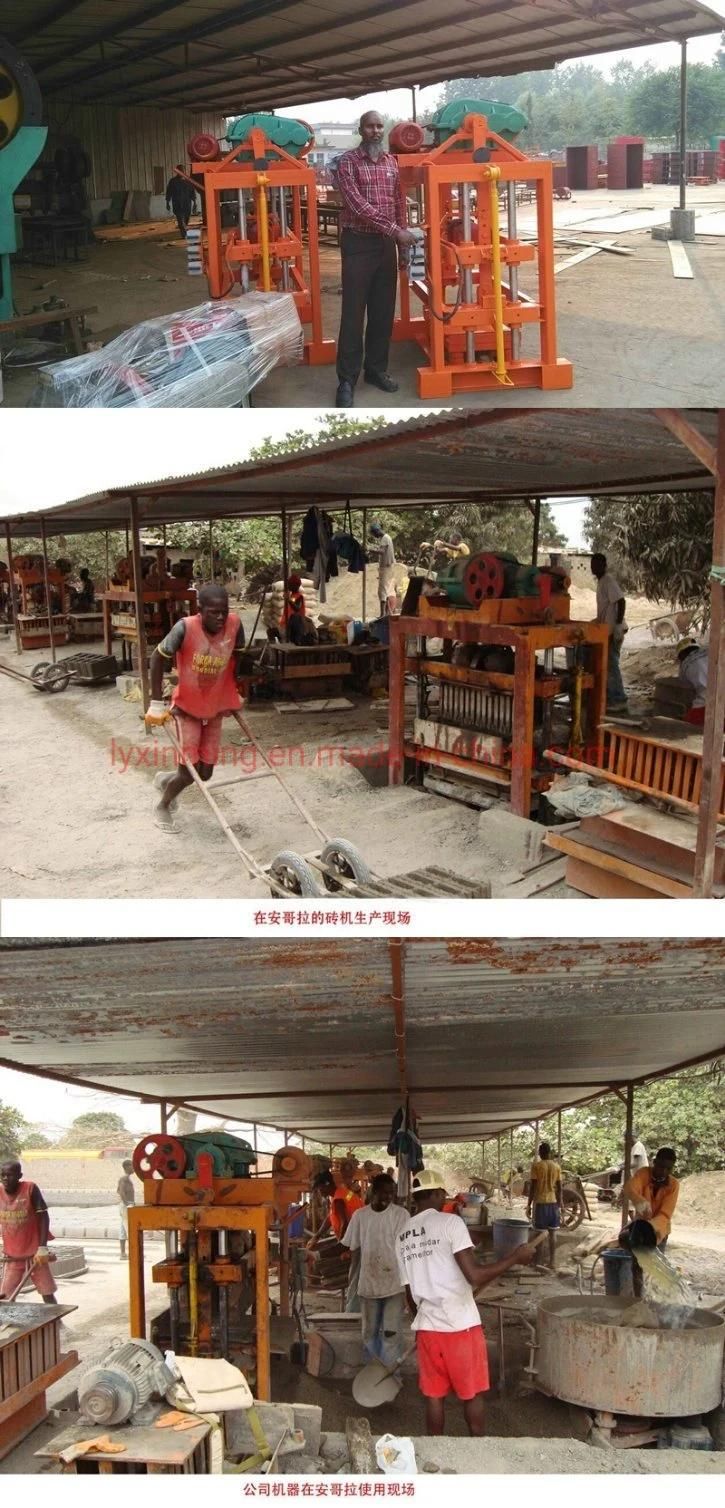

Customers' Feedback

Due to the favorable price and high quality, our QTJ4-40 block making machine is very popular all over the world.

Our Service

Pre-sale

<1>. Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

<2>. Device model choice (recommend the best machine according to the raw material, capacity and the size of brick),

<3>. 24 hours on-line service,

<4>. Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you.

Sale:

<1>. Update the production scheduling in time,

<2>. Quality supervision,

<3>. Product acceptance,

<4>. Shipping on time.

After-sale:

<1>. The engineer will guide to carry out the plant at the clients side if needed,

<2>. Set up, fix, and operate,

<3>. Offer training to the operator until they are satisfied at clients side,

<4>. Skill support the whole using life,

<5>. Recall clients regularly ,get feedback in time ,keep well communication with each other.

click the following contact to send us email !

↓