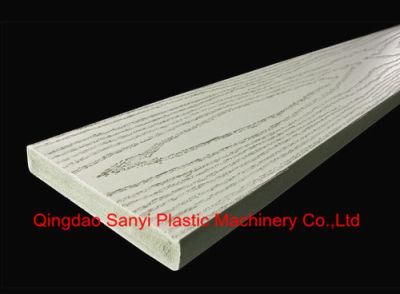

PVC Indoor/ Outdoor Decoration Board Machine

Qingdao Sanyi Plastic Machinery Co., Ltd.- Product Type:Extrusion Molding Machine

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Type:Sheet Extruder

- Screw:Twin-Screw

- Automation:Automatic

Base Info

- Model NO.:SJSZ 80,156

- Computerized:Computerized

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Exhaust:Exhaust

- Transport Package:Wood Package and PE Film Covered, 2 Containers

- Specification:CE, SGS, ISO9001

- Trademark:SanYi

- Origin:Qingdao, Shandong, China (Mainland)

- HS Code:84772090

- Production Capacity:200sets,Year

Description

80/156 conical double screw

OMRON Temperature controller

Output is about 400kg/h.

Automatic feeder

Trimming knife: 3 sets

TOP ELECTRICAL CONFIGURATION

1) Main motor frequency controller: SIMENS or ABB

2)Temperature controller: OMRON or RKC

3) AC controller: SCHNEIDER or SIMENS

4) Thermal overload relay: SCHNEIDER

5) Switch: DELIXI or SCHNEIDER

CHARACTERISTICS OF PVC FOAM BOARD

PVC foam board has such characteristics as sound separation, sound absorption, heat separation.

The material is incombustible, it is safe for use.

All series of products have property of moisture proof, mildew proof, water resistance; its vibration resistant effect is good.

All series of products have property of weathering proof, its luster may remain forever, and it is not easy to be ageing.

This product is light, storage & transport, construction are rather convenient.

This product can be worked with normal tools for wooden material.

Drilling, sawing, nail, bonding can be conducted like wooden material.

It is suitable for thermal shaping, thermal bending and fold processing.

It can be welded; it can also be bonded with other pvc material.

The surface of this product is smooth, it can be printed. (Clean the surface before printing).

FULL SERVICE

1) Pre-sale service:

To provide market research information and consultation

To provide all kinds of convenience and market service

To help customers make project planning and systematic analysis

To maximize customer's satisfaction

To achieve the mutual benefits of our customers and our company

2) After-sale service:

To install products and test products for customers

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories

To provide technical direction according to customers' requirements

To provide technical training for clients' employees

To be responsible for maintenance service, door-to-door service under necessary circumstance

Specifications of PVC Foam Board