760 Zinc Steel Corrugated Sheet Roll Forming Machine Iron Roof Making Machine

Cangzhou Nexus Machinery Co., Ltd.- Warranty:15 Months

- Tile Type:Colored Steel

Base Info

- Model NO.:NM1432

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Electric

- Product Name:760 Zinc Steel Corrugated Sheet Forming Machine

- Raw Material:PPGI Sheet, Gi Sheet

- Feeding Width:914mm,1000mm

- Thickness Range:0.3-0.8mm

- Machine Power:5.5kw+3kw

- Forming Speed:15-20m,Min

- Roller Station:13-15groups

- Operation Type:Touching Screen PLC

- Machine Weight:About 5 Tons

- Transport Package:Plastic Film & Steel Wire Fixed

- Specification:6500mm*1500mm*1500mm(L*W*H)

- Trademark:NEXUS MACHINERY

- Origin:Hebei, China

- HS Code:8455221000

- Production Capacity:30 Sets , Months

- Package size per unit product:850.00cm * 150.00cm * 180.00cm

- Gross weight per unit product:5000.000kg

Description

Basic Info.

Model NO. NM1432 Certification CE, ISO Condition New Customized Customized Usage Roof, Wall Transmission Method Electric Product Name 760 Zinc Steel Corrugated Sheet Forming Machine Raw Material PPGI Sheet, Gi Sheet Feeding Width 914mm/1000mm Thickness Range 0.3-0.8mm Machine Power 5.5kw+3kw Forming Speed 15-20m/Min Roller Station 13-15groups Operation Type Touching Screen PLC Machine Weight About 5 Tons Transport Package Plastic Film & Steel Wire Fixed Specification 6500mm*1500mm*1500mm(L*W*H) Trademark NEXUS MACHINERY Origin Hebei, China HS Code 8455221000 Production Capacity 30 Sets / MonthsPackaging & Delivery

Package size per unit product 850.00cm * 150.00cm * 180.00cm Gross weight per unit product 5000.000kgProduct Description

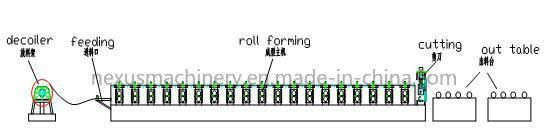

760 Zinc Steel Corrugated Sheet Roll Forming Machine Iron Roof Making Machine1. Processing flow diagram:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic cutting →Output table

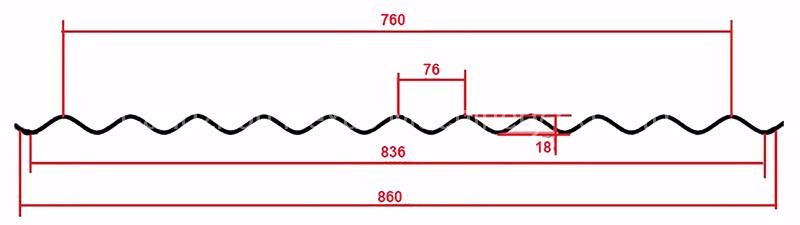

2. Profile Drawings for Reference:

3. Technical parameters for 760 Zinc Steel Corrugated Sheet Roll Forming Machine Iron Roof Making Machine :

1 | Suitable to process | Color steel plate |

2 | Width of the plate | 914mm/1000mm |

3 | Thickness of the plate | 0.3-0.8mm |

4 | De-coiler | Manual one, can load 5 tons raw material |

5 | Rollers for forming | 15 rows |

6 | Diameter of the roller | 76mm |

7 | Rolling material | Carbon Steel 45# |

8 | Main motor power | 5.5kw |

9 | Productivity | 15-20m/min |

10 | Cutting method | Hydraulic mould cutting |

11 | Material of the cutting blade | Cr12 |

12 | Hydraulic cutting power | 3kw |

13 | Processing precision | Within 1.00mm |

14 | Control system | Delta PLC control |

15 | Side panel of machine | 18mm |

16 | Main structure of the machine | 350 H steel |

17 | Weight | About 4.6T |

18 | Dimensions | 7.5*1.6*1.2m |

19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

20 | Certificate | CE/ISO |

4. Equipment list :

| No. | Product Name | QTY |

| 1 | 5T Manual decoiler | 1 |

| 2 | 760 Zinc Steel Corrugated Sheet Roll Forming Machine Iron Roof Making Machine (Includes Hydraulic cutting, PLC computer, Electrical cabinet, Hydraulic system) | 1 |

| 3 | Passive Output table | 2 |

| Sum | 4 |

Photos of 760 Zinc Steel Corrugated Sheet Roll Forming Machine Iron Roof Making Machine for Reference:

ABOUT US:

Cangzhou Nexus Machinery Co.,Ltd is experienced manufacturer & exporter of cold roll forming machine with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, so we are able to assist customers with professional designing and solution.

Our range of products: roof tile roll forming machine, cladding roll forming machine, metal decking roll forming machines, C/U/Z/W/L steel purlin roll forming machine etc. We also can supply steel coils, roof panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Azerbaijan and Kazakhstan.

We have rich experience for cold roll forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.