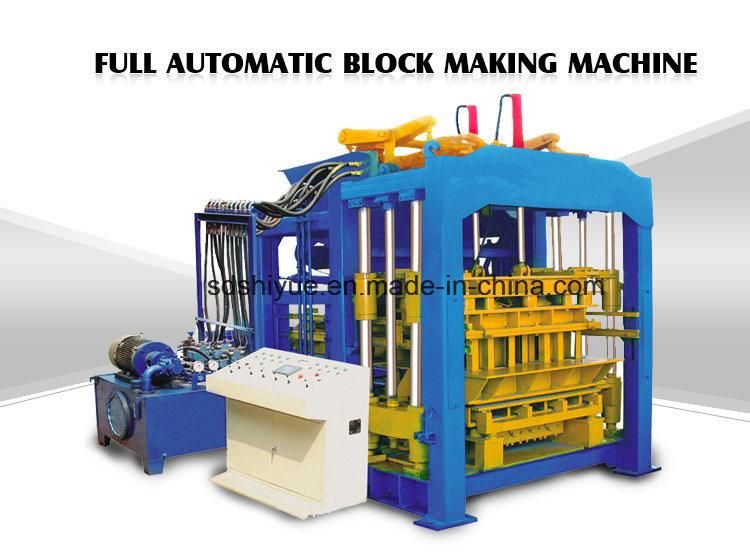

Qt8-15 Concrete Block Manufacturing Machine Price

Shandong Shiyue Intelligent Machinery Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Product Name:Fully Automatic Concrete Block Machine

- Method:Hydraulic Pressure

Base Info

- Model NO.:QT8-15

- Rated Pressure:21MPa

- Main Vibration:Platform Vibration

- Color:as Your Request

- Raw Material:Crushed Stone, Cement, Cinder, Clay etc

- Vibration Frequency:2800-4500r ,Min

- Molding Cycle:15-20s

- Overall Power:44kw

- Equipped with Mixer:Js750

- Transport Package:Nude Package or Plastic Packing or Wooden Package

- Specification:9350*2320*2950mm

- Trademark:SHIYUE

- Origin:Shandong, China

- HS Code:8474802000

- Production Capacity:3600 Sets,Set

Description

Basic Info.

Model NO. QT8-15 Rated Pressure 21MPa Main Vibration Platform Vibration Color as Your Request Raw Material Crushed Stone, Cement, Cinder, Clay etc Vibration Frequency 2800-4500r /Min Molding Cycle 15-20s Overall Power 44kw Equipped with Mixer Js750 Transport Package Nude Package or Plastic Packing or Wooden Package Specification 9350*2320*2950mm Trademark SHIYUE Origin Shandong, China HS Code 8474802000 Production Capacity 3600 Sets/SetProduct Description

Introduction

Our machine,with harmonic cooperation between electric and hydraulic machines functions, guarantee a reliable and high output production of hollow block,brick, fly ash brick,paver, interlock brick, curbstone

1).Use Janpan Mitsubish PLC control system and Siemens Motors:

A.Mitsubish PLC, with great adaptability,guarantee the stability and reliability of the machine

B.Visualization touch screen with easy operation

C.Siemens Motors, Higher degree of protection, to ensure the use of safe and reliable for customers, improve parts connection reliability

2).Hydraulic system

Hydraulic components made in Taiwan, we use high-dynamic proportional and directional

valves, which automatically adjust the oil flux and pressure as per specific working requirements, this design greatly prevent the cylinder from damage

3).360° Multi-Shaft Rotating and Compulsory Feeding

A.Speedy and rotating feeding, with uniform mixing, to make sure that the density and intdensity of the products are guaranteed

B.This uniform feeding is applicable for different kinds of raw materials and moulds

4).Use heat treatment on moulds and main parts of the machines

A.Heavy duty machine structure and wear resistant moulds

B.This greatly improves the using lifetime of the machine moulds

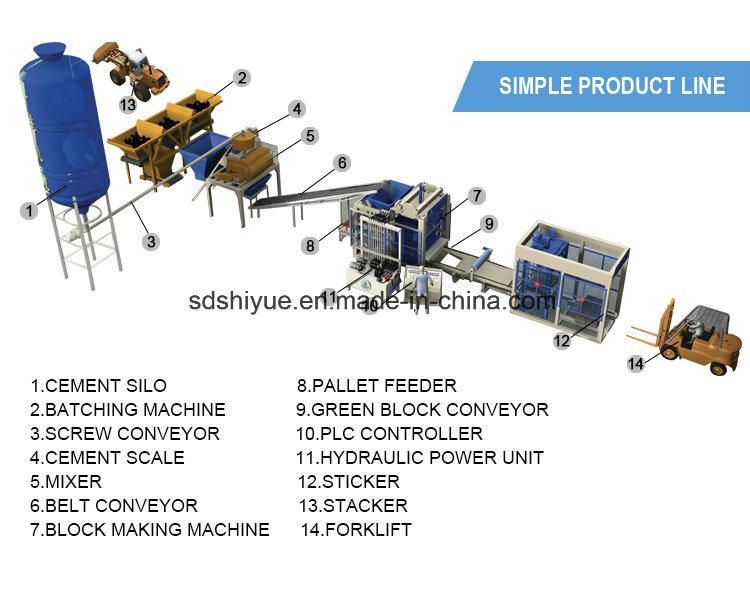

Machine Parameters

Dimension of host machine | 8300*1860*3000mm | control style | PLC |

forming style | Hydraulic | Vibration force | 60KN |

vibrator style | table and mould vibrate togather | raw material feeding style | 360 degree revole |

forming hight | 40-250mm | moulding period | 15-20S |

moulding aera | 800*820mm | size of pallet | 950*900*25mm |

weight of host machine | 12.5T | Mixer style | JS750 |

Overall Power | 55.5KW | Voltage | 220/240/380/440V |

Productivity

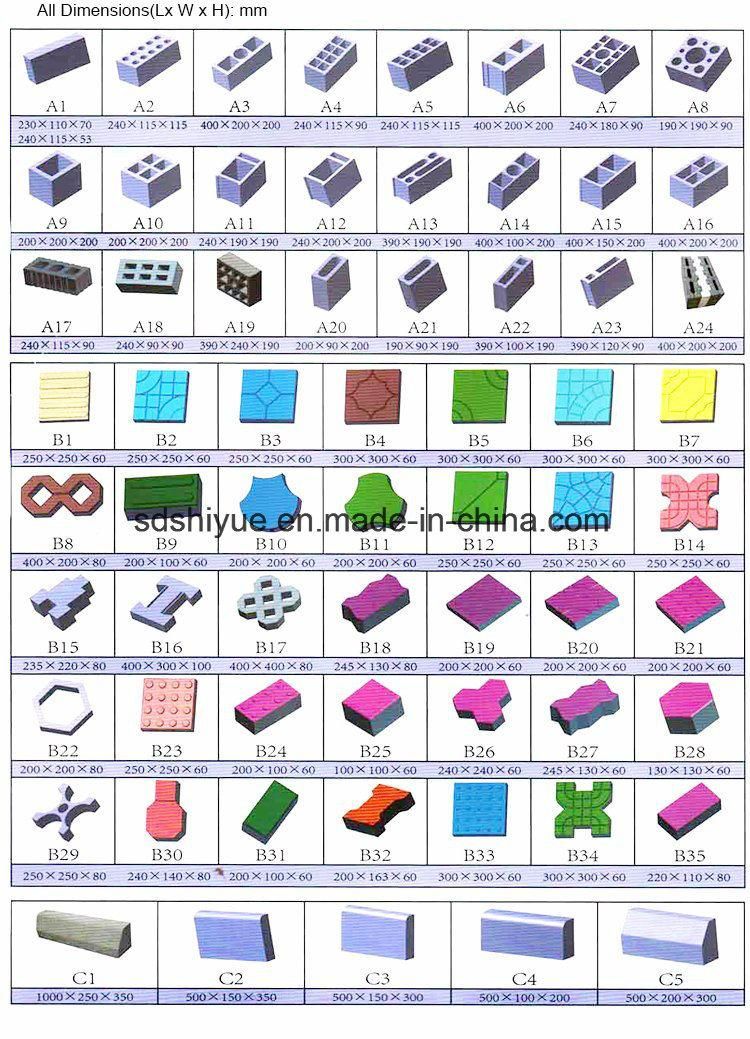

Size(L * W * H) | Pcs /Mould | Pcs / Hr | Pcs / 10Hr |

400*100*200mm | 14 | 2100-2940 | 21000-29400 |

400*150*200mm | 10 | 1500-2100 | 15000-21000 |

400*200*200mm | 8 | 1200-1680 | 12000-16800 |

400*250*200mm | 6 | 900-1260 | 9000-12600 |

240*115*90mm | 21 | 3780-5040 | 37800-50400 |

240*115*53mm | 42 | 9000-10000 | 90000-100000 |

Block sample

Shipping and delivery

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Brick machine equipments finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

Our service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of build factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) Welcome to visit our factory and production line anytime

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side.

(2) Set up, fix,and operate

(3) Will not stop training the operator until they are satisfied at clients side.

(4) 24 hours service

(5) Recall clients regularly ,get feedback in time,keep well communication with each other.

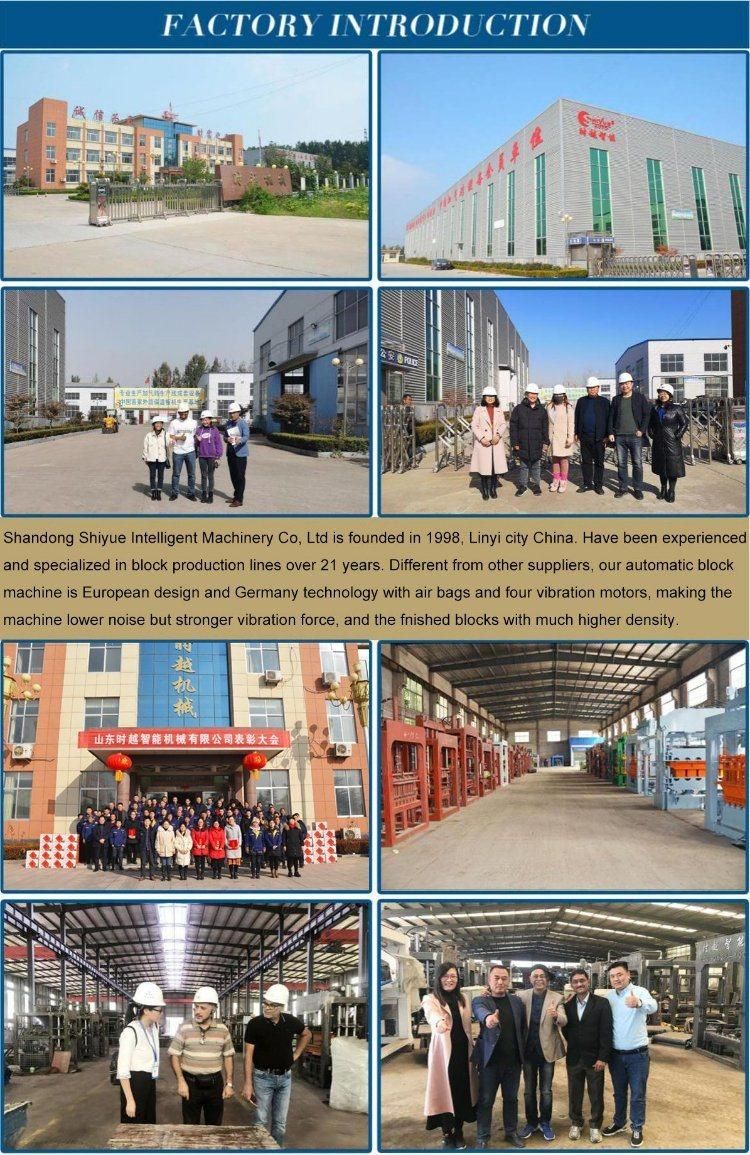

Our factory

FAQ

1.Question:Does the machine could change mold?

Answer:Yes,this machine could change different kinds of mold.The machine could produce interlock, paver size depending on your local requirements.

2.Question:What is the electric voltage and rate?

Answer:Our local electric voltage is 380v, 3phase, 50hertz, the electricl voltage can be revised according to local situation.

3.Question:How about the service life of this machine?

Answer:This machine could work for about 6-10 years if your side maintain well.

4.Question:What's your machine warrenty?

Answer:12 months guarantee,we send more spare parts for you when shipping machine to you.

5.Question: The mode of transportation.

Answer: by sea, by land or by rail according to customer local need