Qt6-15 Concrete Brick Cement Hollow Block Forming Machine in Kenya

Nantong Hengda Non-Burned Machinery Engineering Co., Ltd.- Certification:ISO9001: 2000, CE, SGS

- Customized:Customized

- Automatic Grade:Automatic

- Type:Concrete Block Making Machine

- Color:Blue

- Weight:10t

Base Info

- Model NO.:QT6-15

- Material:Steel

- Control:PLC

- Vibration Form:Table and Mould

- Method:Hydraulic Pressure

- Processing:Brick Production Line

- Product:Brick

- Brick Raw Material:Concrete

- Automation:Automatic

- Transport Package:NO PACKAGE

- Specification:QT6-15

- Trademark:HENGDA

- Origin:china

- HS Code:8474809090

- Production Capacity:1440PCS,HOUR

Description

yield

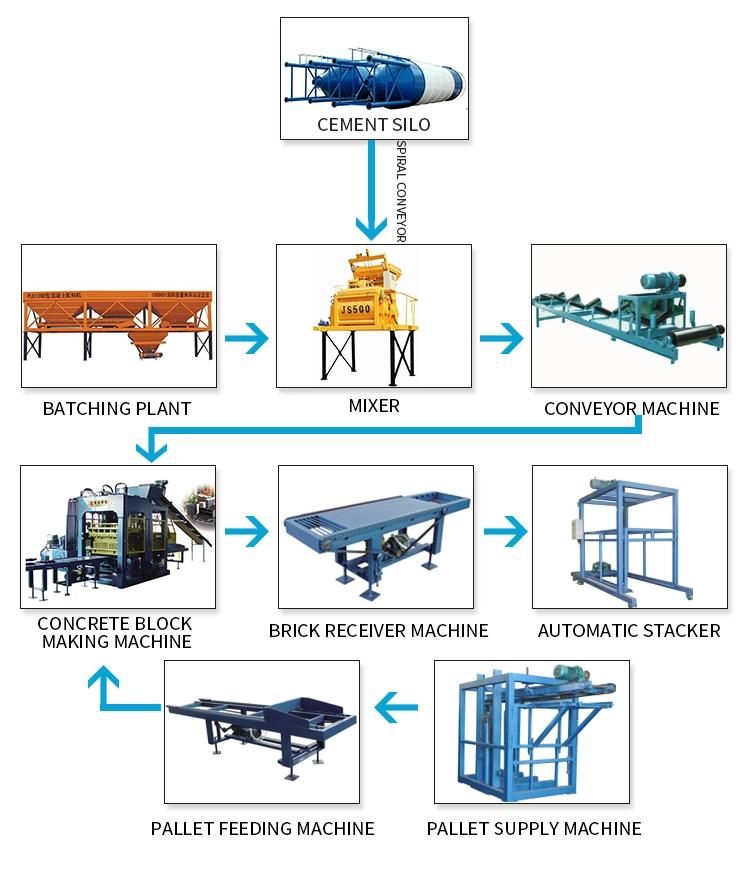

QT6-15 block making machine flow chart

Block samples

Big Five Advantages Of HENGDA automatic Cement Brick Machines:

Our machines, with harmonic cooperation between mechanical, electrical and hydraulic machines functions, guarantee a reliable and high output production of concrete products

Use LG PLC control system and LG Touch Screen,

A. LGPLC, with great adaptability, guarantees the stability and reliability of the machine.

B. Visualization touch screen, with easy operation;

2. Use Frequency Conversional Control Technology, which controls the block making:

A. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

B. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

C. Power saving: 30%;

3. Use doubles high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

A. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

B. Guarantee production stability;

4. 360° Multi-Shaft Rotating and Compulsory Feeding:

A. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

B. This uniform feeding is applicable for different kinds of raw materials and moulds;

5. Use heat treatment on moulds and main parts of the machines:

A. Heavy duty machine structure and wear resistant moulds;

B. The hardness reaches up to HRC 52-58;

C. Greatly improves the using lifetime of the machine by 50%.

Buying tips

We have two kinds of brick machine, one produce clay brick machine, another produce concrete block machine , when you want to buy, you please tell me

1. You need clay brick machine or cement brick machine?

2. Your brick size( length, width and height)

3.Your brick picture and brick production

My contact information

Name: Maggie

3.Your brick picture and brick production

We are professional clay brick machine, concrete block machine and block pallet manufacturer, if you are interested, please come here.