Drywall Profile U Track Roll Forming Machine

Cangzhou Nexus Machinery Co., Ltd.- Warranty:1 Year

- Certification:CE, ISO9001

- Customized:Customized

- Condition:New

- Control Type:Electric

- Automatic Grade:Automatic

Base Info

- Model NO.:60-27-28

- Product Name:Drywall Profile U Track Roll Forming Machine

- Coil Material Thickness:0.3-0.8mm

- Processing Material:Galvanized Steel

- Roller Material:Cr12MOV

- Forming Speed:About 8-25m,Min

- Main Motor Power:5.5kw (Depend on Final Design)

- Hydraulic Station Power:2.2kw (Depend on Final Design)

- Controlling System:Mitsubishi PLC & Converter

- Number of Work Stations:12stations

- Max. Roll Shaft of Diameter:76mm

- Transport Package:1.Control Box and Easy Damaged Parts:Protective PA

- Specification:60-27-28

- Trademark:Nexus Machinery

- Origin:Cangzhou

- HS Code:8455221000

- Production Capacity:10

Description

Basic Info.

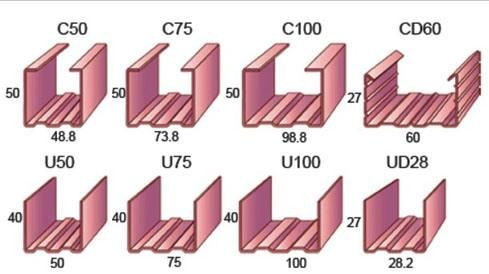

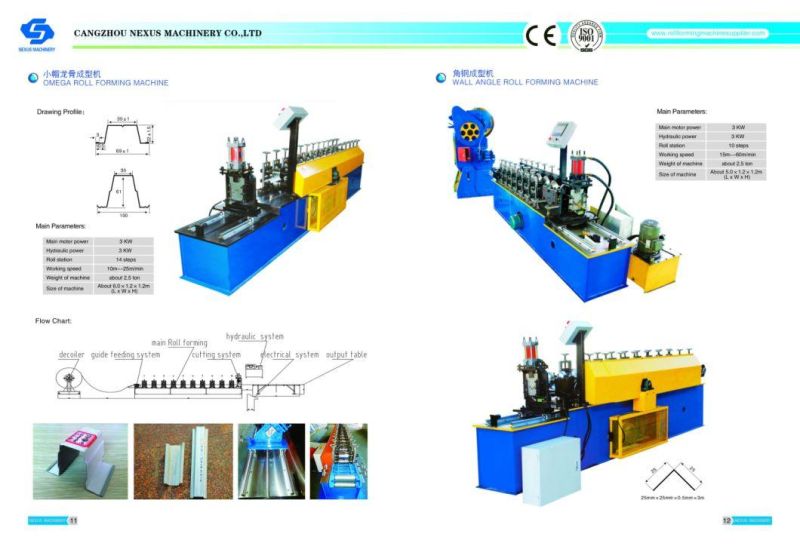

Model NO. 60-27-28 Product Name Drywall Profile U Track Roll Forming Machine Coil Material Thickness 0.3-0.8mm Processing Material Galvanized Steel Roller Material Cr12MOV Forming Speed About 8-25m/Min Main Motor Power 5.5kw (Depend on Final Design) Hydraulic Station Power 2.2kw (Depend on Final Design) Controlling System Mitsubishi PLC & Converter Number of Work Stations 12stations Max. Roll Shaft of Diameter 76mm Transport Package 1.Control Box and Easy Damaged Parts:Protective PA Specification 60-27-28 Trademark Nexus Machinery Origin Cangzhou HS Code 8455221000 Production Capacity 10Product Description

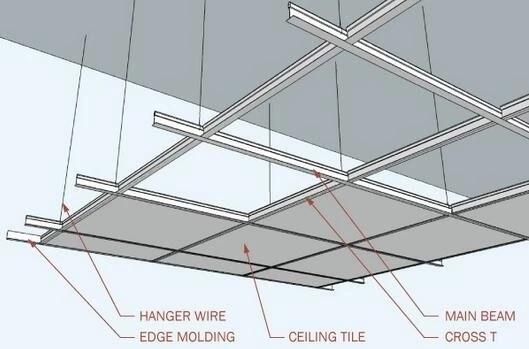

Drywall Profile U Track Roll Forming MachineDrywall Profile U Track Roll Forming Machine offer builders a competitive alternative to traditional wood trusses.This machine provides significant improvements over other light gauge steel trusses currently available. Flexibility and design advantages allow architects, engineers, contractors and owners' exceptional versatility and performance characteristics not available with any other type of truss material.Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling. No matter for running business or for big construction, this machine will be good helper for you

Technical Parameters:

♥Suitable material: color steel sheet or galvanized steel sheet

♥Thickness of raw material: 0.3-0.8mm

♥Yield strength of material: 235Mpa-345Mpa

♥Forming speed: about 8-25m/min

♥Power Requirement :

Main motor power: 5.5Kw (Depend on final design)

Hydraulic station power: 2.2Kw (Depend on final design)

♥Uncoilers loading capacity Max. Capacity: 3000kgs (can be increased to be 10T)

♥Controlling system: Mitsubishi PLC & Converter

♥Machines weight: about 3-4T for different profile machine.

♥Machines size: about 3.8m×1.5m× 1.4m (Depend on final design)

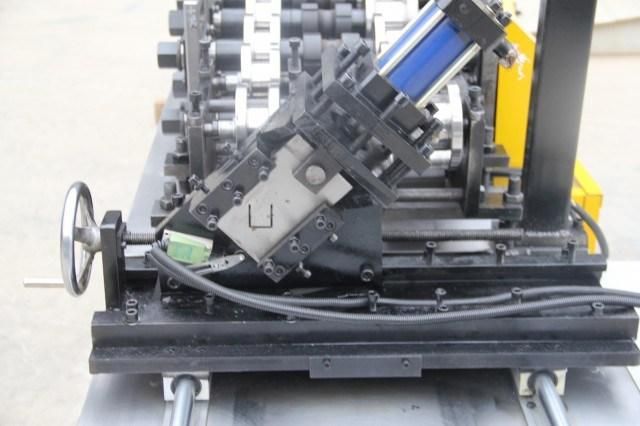

2.Material of Main Equipment:

♥Roller Material:High grade No.45 forged steel, with digital-controlled procession,

Plated with hard chrome.

♥Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft diameter is 50mm.

♥Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

♥Cutter blade and punch dies: Cr12 mould steel with quenched treatment

- Number of Work Stations..........................12stations

- Max. Roll shaft of Diameter..........................76mm

- Overall L x W x H (Approx.)...............3.8M*1.2M*1.6M

- Roller material: GCR15 quenched 58°-62°,chromed

- Outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

- Transducer: Panasonic

- Cages.......................... use the strong steel nets

- Levelling screws on base ............with Thick metal paltes

ABOUT US:

FAQ:

1. How long the machine could be made?- Normally speaking, light gauge steel frame machine could

be made without 45 working days. If you need machines in a hurry, we can make it for you

less than a month.

2. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours), then we can

pick up you.

3. Do you have after sales support?

-Yes, we are happy to give advice and we also have skilled technicians available across the

world.We need your machines running in order to keep your business running.