Cutting Machine Aluminum Auto Parts Milling, Drilling, Cutting Machine

JINAN YUEFENG MACHINERY CO., LTD.- Condition:New

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:380V

- Model:Lzx-CNC-3500

Base Info

- Model NO.:Lzx-CNC-3500

- Input Voltage:380V 50Hz

- Input Power:8.5kw

- Spindle Power:5.5kw

- Spindle Speed:18000r,Min

- X-Axes Travel:3550mm

- X-Speed:0~60m,Min

- Max Loading Profile Length:3100mm

- Y-Axes Travel:300mm

- Horizontal Max Width:280mm

- Y-Speed:0~30m,Min

- Z-Axes Travel:240mm

- Three Side Processing Height:120mm

- Single Profile Processing Height:200mm

- Z-Speed:0~30m,Min

- Transport Package:Wooden Box

- Specification:4000*1600*2100mm

- Trademark:YueFeng

- Origin:China

- HS Code:8477800000

- Production Capacity:40 Window Per Day

Description

Basic Info.

Model NO. Lzx-CNC-3500 Input Voltage 380V 50Hz Input Power 8.5kw Spindle Power 5.5kw Spindle Speed 18000r/Min X-Axes Travel 3550mm X-Speed 0~60m/Min Max Loading Profile Length 3100mm Y-Axes Travel 300mm Horizontal Max Width 280mm Y-Speed 0~30m/Min Z-Axes Travel 240mm Three Side Processing Height 120mm Single Profile Processing Height 200mm Z-Speed 0~30m/Min Transport Package Wooden Box Specification 4000*1600*2100mm Trademark YueFeng Origin China HS Code 8477800000 Production Capacity 40 Window Per DayProduct Description

Cutting Machine Aluminum Auto Parts Milling, Drilling, Cutting Machine

1. This machine is mainly used for processing all kinds of mounting holes, lock holes,

1. This machine is mainly used for processing all kinds of mounting holes, lock holes,launders and other slots on various profiles.

It can work on aluminum alloy, non-ferrous metal, orbit construct and pvc profiles, etc.

Once clamping, multiple hole drilling and milling be finished, high efficiency.

2.Linear guide kinematic pair, ball screw, gear rack and imported servo motor be adopted in this machine,

results high stable and accuracy for locating and processing.

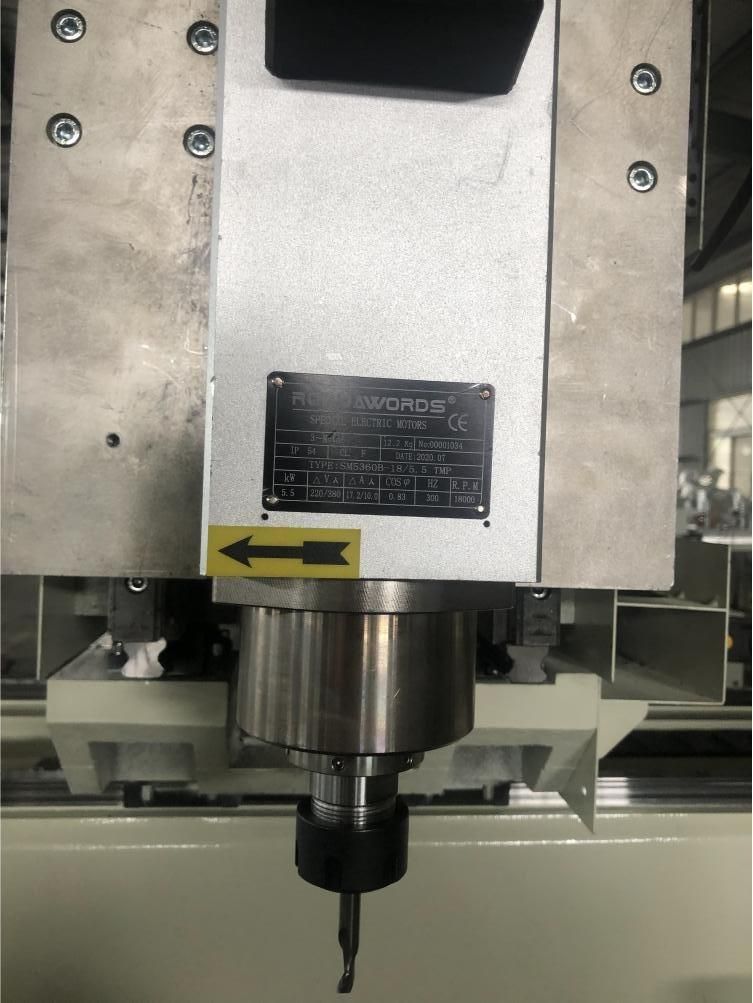

3.The main shaft adopts RUIDEWOSI, results stable rotation, small noise and high efficiency.

4. Adopts whole set of CNC system, Interface is simple and intuitive, makes the operation more convenient.

ONE TIME CLAMPING, IT CAN PROCESS THREE SIDE.

Technical Parameter:

Model LZX-CNC-3500

Input voltage 415V 50Hz

Input power 8.5Kw

Spindle power 5.5Kw

Spindle speed 18000r/min

X-axes travel 3550mm

X-speed 0~60m/min

Max loading profile length 3100mm

Y-axes travel 300mm

Horizontal Max width 280mm

Y-speed 0~30m/min

Z-axes travel 240mm

Three side processing height 120mm

Single profile processing height 200mm

Z-speed 0~30m/min

Process range 3500×200×250mm

Overall dimension 4000×1600×2100mm

MAIN PARTS BRAND:

Controlling system: SYNTECH

Frenquency Transformer: Delta 5.5kw

Solinoid Valve : AIRTECH

Electronics: SCHNEIDER

All Pipe: Esun(china-italy brand)

All screws: JINYI (TAIWAN)

Spindle: RUNDEWORDS

Servodriver : YASKAWA

Servomotor : YASKAWA

Conveyer: by grinded gear rack, TAIWAN TPI

Detail Parts of CNC Aluminum Window Machine for Drilling Milling Holes Slots

1.RUNDAWORDS SPINDLE

2.SYNTEC SYSTEM WITH INLELLIGENCE INTERFACE SCREEN AND SCHNEIDER SWITCH

3.DELTA FRENQUENCY TRANSFORMER AND SYTECH PLC

4.YASKAWA SERVODRIVER

5.YASKAWA SERVOMOTOR

6.TAIWAN YYC GEAR RACK

7.AUTONICS SENSOR

8.TAIWAN TBI LINEAR GUIDE

Please contact us for more machine details

FAQ

FAQ1.Are your company a trading one or a factory?

Factory + trade (integration), 36 years' focusing on Upvc,Aluminum Window and Doors Equipment ,insulating glass equipment and curtain wall equipment.

2.After an order is placed, when to deliver?

♦ Generally about 15 days, If we have inventory, we can arrange shipment within 5 days.

♦ Please be aware that our production lead times depend on specific items and item quantities.

3.What about the warranty with after - sales services?

♦ 24 months warranty. Besides,we can help you to solve your problem freely;

♦ After the warranty, the professional after-sale service team will provide perfect technical support,and help customer solve problem encountered while using our product, handles guest problems and complaints in a professional and timely.

4.What about the services and product' quality?

♦ Each machine must be carried out 100% quality examination and test before shipment.

♦ And all machines meet ISO and CE certification.

5. We don't know the machine operation, what should we do?

♦ We can send engineer to your place, or we provide video training to show you how to install & operate, let engineer help you online.