Factory of Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery

Cangzhou Longlize International Trade Co., Ltd.- After-sales Service:18 Months

- Warranty:18 Months

- Product Type:Floor Deck Roll Forming Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Floor Deck Roll Forming Machine

Base Info

- Model NO.:688,720,750,1025,915

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Application:Floor Deck Roll Forming Machine

- Color of Machine:Yellow and Blue

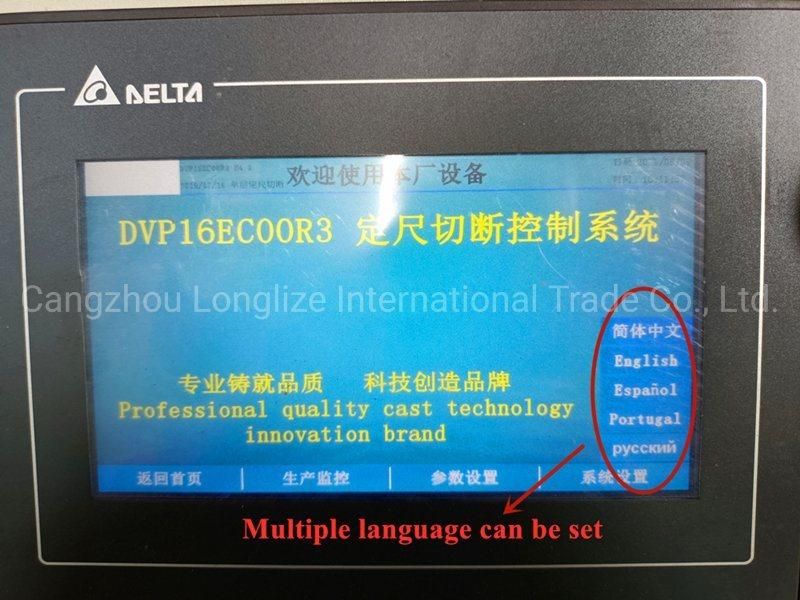

- Language:Chinese & English,as Customer′s Request

- Cutting Type:Hydraulic -Cutting

- Transport Package:on The Sea

- Specification:688,720,750,1025,915

- Trademark:LLZ

- Origin:China

- HS Code:84552210

- Production Capacity:500 Sets Per Year

Description

Basic Info.

Model NO. 688/720/750/1025/915 Certification CE, ISO Condition New Customized Customized Application Floor Deck Roll Forming Machine Color of Machine Yellow and Blue Language Chinese & English/as Customer′s Request Cutting Type Hydraulic -Cutting Transport Package on The Sea Specification 688/720/750/1025/915 Trademark LLZ Origin China HS Code 84552210 Production Capacity 500 Sets Per YearProduct Description

Factory Of Floor Deck Roll Forming Machine Steel Decking Sheet Making MachineryProduct Description

| 1 | Coil Width | 914mm/1000mm/1200mm /1250mm or according to your request |

| 2 | Forming thickness | 0.6mm-1.5mm |

| 3 | Diameter of shaft | 90mm/100mm(Reinforcement part) |

| 4 | Material of shaft | 45#steel with tempering |

| 5 | Middle plate | 18mm |

| 6 | Main frame | 400H steel |

| 7 | Main power | 2*11kw/2*15kw according to machine |

| 8 | Voltage/Power | 3 Phase,380 Voltage,50Hz/as customer's request |

| 9 | Cutting type | hydraulic stop to cut |

| 10 | Control method | PLC |

| 11 | Brand of electrical parts | Delta |

| 12 | Length control | Encoder |

| 13 | Forming speed | 8-12meters/min |

| 14 | Operation | Touch Screen |

| 15 | Language | Chinese & English/as customer's request |

| 16 | Manual decoiler | 8 tons |

| 17 | Dimensions(L*W*H) | about 14*1.6*1.4M |

| 18 | Weight | about 11 tons |

Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery--It adopts coiling steel sheet as the raw material, decoiling, continuous rolling and cold-forming, automatically cut to the size and specification which is required, and output the finished panels.

Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery--It adopts coiling steel sheet as the raw material, decoiling, continuous rolling and cold-forming, automatically cut to the size and specification which is required, and output the finished panels.Galvanized Floor Decking Roll Metal Forming Machine adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery Direction for use

1)Fill hydraulic oil in the pump.not too full,three quarters are ok.

2)Connect electric wires,use 5-10mm² support line and keep grounding.

3)Put all necessary parts on the right location.

4)Feed raw materil into the machine slowly,make it run smoothly then automatic.

5)Pay attention to final sheet collection,do not scretch it or hurts people.

Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery Custom service requirements.

1)Final sheet embossing is avaliable.we can different embossing rollers on various pattern and drawings.

2)Feeding material width should be confirmed before machine design .the width are changeable,

3)Both three and two waves are suitable for the line.we can design the machine based on buyer's profile drawing.

4)Material thickness normal range are 0.6-1.5mm.if you have any special request on material thickness,we should discuss in advance .

5)Cutting are provided as you want.

Floor Deck Roll Forming Machine Steel Decking Sheet Making Machinery Standard Packing:

1)Steel wire fix the machine into the container, in case any damage when shaking on the sea.

2)The main body of the roll forming machine will be naked packing into the container,covered with plastic film.

3)The received goods table put into carton box .

4)Manual decoiler naked package .

5)The spare parts will be packed into the carton box.