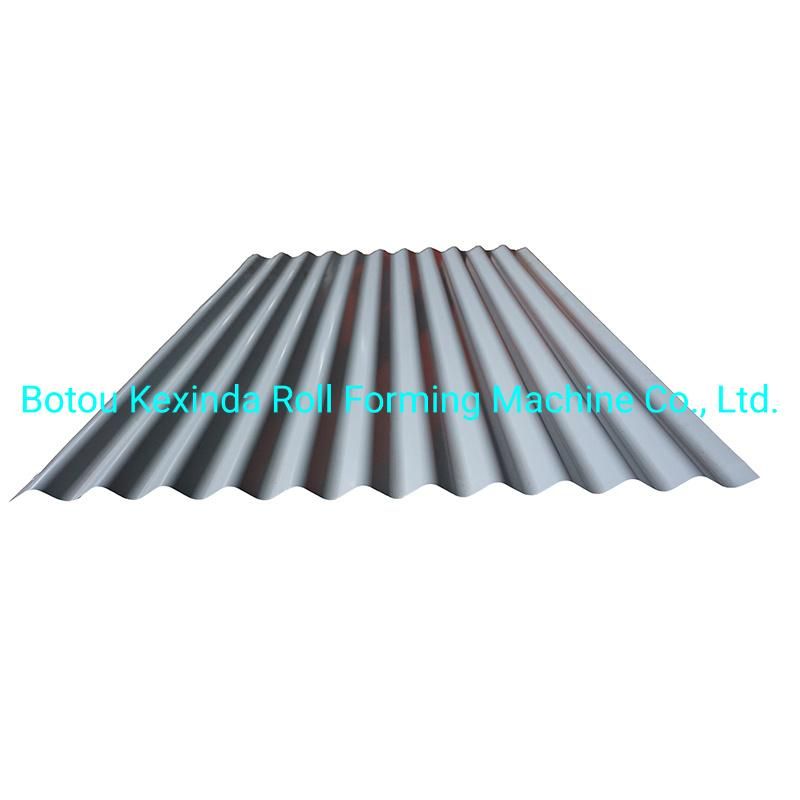

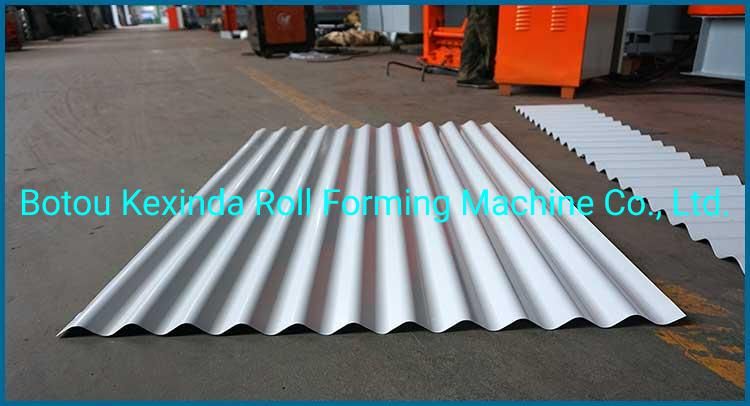

Crrugated Roof Metal Steel Sheet Roll Forming Machine

HEBEI XINNUO ROLL FORMING MACHINE CO., LTD.- Product Type:Tile Making Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:KXD

- Customized:Customized

- Weight:4t

- Size:7.2*1.4*1.2m

- Productivity:8-12m,Min

- Power:3+3kw

- Thickness of The Plate:0.3-0.8mm

- Voltage:380V 50Hz 3phases

- Processing Precision:Within 1.00mm

- Control System:PLC Control

- Material of The Cutting Plate:Cr12

- Diameter of The Roller:80mm

- Transport Package:Seaworthy Package

- Trademark:KXD

- Origin:China Mainland

- HS Code:84552210

- Production Capacity:7000 Sets ,Year

Description

Process Sketch:

Uncoiling →Infeed guiding →Roll forming →Pressing→Measure Length&Shearing →Sheet to Support Table

Packaging & Shipping

1.One 40ft container for loading one set machine with manual decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3.Spare parts and some small parts packed in plastic tooling box;

4.All Components Fixed by steel wire with Container.

ABOUT US

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

FAQ

1:How to play order:

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport:By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can

pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4.What's the after- sale service:

we sent technician to your country to fix the machine.The buyer should bear all the cost including:

visa, round trip ticket and suitable accommodation, also buyer should pay the salary 80USD/day.

5.How about the warranty: 12 months limits warranty

CONTACTION

Contact Person: Sunny Liu