Oil Casing Production Line Seamless Pipe Machine

Shanxi Haina H-tech Precision Machinery Co., Ltd.- After-sales Service:Lifetime Warranty

- Warranty:12 Months

- Pipe Material:Stainless Steel

- Condition:New

- Customized:Customized

- Theory:Inverter

Base Info

- Model NO.:HNWF

- Application:Industry

- Type:Pipe Mill

- Thickness:5 - 40 mm

- Annual Output:300,000 Tons

- Transport Package:Container

- Specification:Φ 114 - Φ 711 mm

- Trademark:HNGK

- Origin:China

- HS Code:8501109101

- Production Capacity:5 Sets

Description

Basic Info.

Model NO. HNWF Application Industry Type Pipe Mill Thickness 5 - 40 mm Annual Output 300,000 Tons Transport Package Container Specification Φ 114 - Φ 711 mm Trademark HNGK Origin China HS Code 8501109101 Production Capacity 5 SetsProduct Description

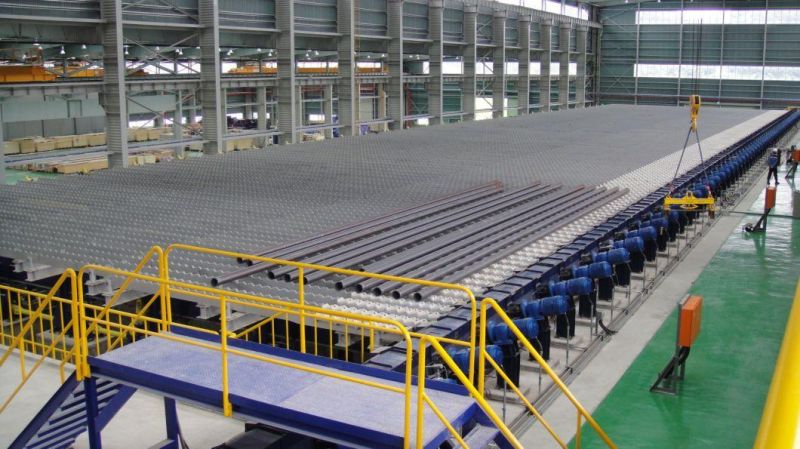

Oil Casing Production Line Seamless Pipe Machine

Everyone is used to naming hot-rolled seamless pipe mills with mandrels for the wall forming process, such as MPM mills and Assel mills. There are two main types of pipe rolling mills, one is a continuous rolling mill, and the other is a cross rolling mill. According to the mandrel operation mode, the continuous rolling mill can be divided into three types: floating mandrel, limited mandrel and semi-floating mandrel. The limited mandrel mill can be divided into two-roll type (MPM) and three-roll type (PQF). The skew rolling mill is divided into three-high rolling mill (Assel) and two-high rolling mill (Accu Roll).

The continuous pipe rolling mill is suitable for the production of large quantities of steel pipes, with high output, long rolled steel pipes (the length of the waste pipe can exceed 30m), the quality of the inner and outer surfaces of the product is good, the specification range is wide, and the D/S is large (over 42). However, its investment is large, there are many spare parts for tools, and it takes a long time to change specifications.

The skew rolling mill is suitable for the production of small batches and multiple varieties of steel pipes. It has low investment, fewer tools and spare parts, low tool consumption, and flexible production. However, the output is low and the rolled steel pipes are shorter (the length of the waste pipe is generally not more than 15m). For thin-walled tubes, the surface quality is unstable, the specification range is narrow, and the D/S is small (generally less than 40).

Production Process:

Billet Feeding → Inspecting → Grinding → Sawing → Heating → Piercing → Pipe Rolling → Reducing Diameter → Cooling → Straightening → Pipe Cutting → Water Pressure Testing → Flat Head Chamfering → Manual Inspecting → Weighing, Measuring and Marking → Packing

Models:

Unit 114mm Unit 219mm Unit 273mm Unit 325mm Unit 406mm Unit 508mm Unit 630mm Unit 711mm

Packing & Shipping

1. We use steel wire and wooden frame to fix the pipe mill.

2. In addition, used shockproof film to protect the main motors.

3. We use containers for shipping.

4. Generally speaking, we start at Tianjin sea port, but we also can start at other port according to customers need.

Our Factory

Our Customer

Integrated Services

1. Provide customers with a reasonable investment plan, filter the appropriate models recommended to customers.

2. Free equipment drawings, customer plant equipment planning drawings.

3. Provide the base map required for installation free of charge.

4. Provide equipment installation and commissioning until the buyer operates normally.

5. Provide professional technical training, as soon as possible to allow the buyer's operator to master the operation and use of the equipment.

6. Provide and coordinate auxiliary equipment, accessories, and consumables.

7. The warranty period is one year, except man-damage. If you have any question in operation in operating the machines, you can call us or send emails, we will solve the problem for you asap.