Hr1-30 Simple Manual Soil Interlocking Brick Machine, Easy Operate Brick Machine, for Small Brick Making Plant

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- After-sales Service:24-Hours

- Warranty:3 Years

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Manual

- Type:Hand Press

Base Info

- Model NO.:HR1-30

- Colour:According to Your Demand

- Mold:Changeable, Steel Casting Molds

- Price:Cheap and Rational

- Material:Soil Cement Mixture

- Weight:220kg

- Brick Style:Lego Interlocking Bricks

- Machine Style:Eco Maquinas

- Molding Cycle:25-30s

- Overall Size:890X300X1300mm

- Rated Pressure:6MPa

- Transport Package:0.75 Cbm with Iron Box Package

- Specification:CE SGS ISO

- Trademark:HENRY

- Origin:China(Mainland) Shandong Linyi

- HS Code:8474802000

- Production Capacity:120-200 PCS of 250X125X60mm Per Hour

Description

Basic Info.

Model NO. HR1-30 Colour According to Your Demand Mold Changeable, Steel Casting Molds Price Cheap and Rational Material Soil Cement Mixture Weight 220kg Brick Style Lego Interlocking Bricks Machine Style Eco Maquinas Molding Cycle 25-30s Overall Size 890X300X1300mm Rated Pressure 6MPa Transport Package 0.75 Cbm with Iron Box Package Specification CE SGS ISO Trademark HENRY Origin China(Mainland) Shandong Linyi HS Code 8474802000 Production Capacity 120-200 PCS of 250X125X60mm Per HourProduct Description

HR1-30 simple manual soil interlocking brick machine, easy operate brick machine, for small brick making plant

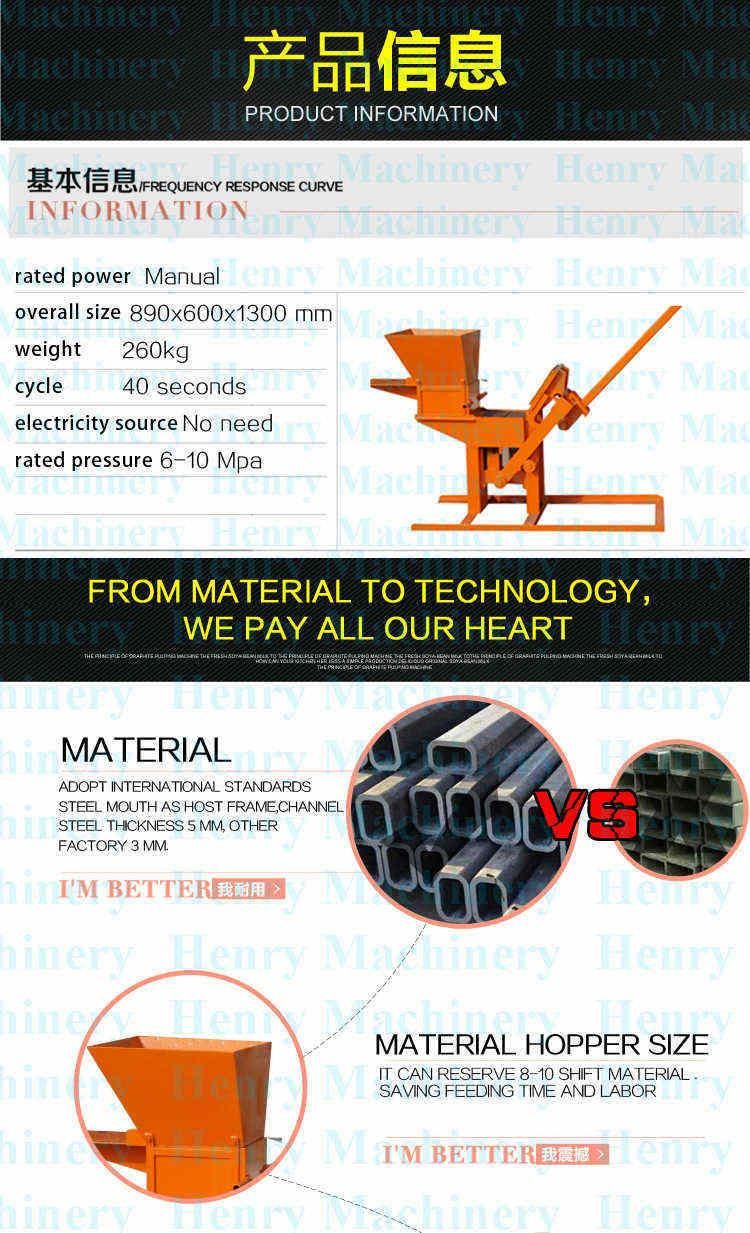

Brick machine specification

| rated power | Manual |

| overall size | 890x600x1300 mm |

| weight | 260kg |

| cycle | 30 seconds |

| electricity source | No need |

| rated pressure | 6 Mpa |

Advantages of HR1-30 soil brick machine

1) The cheapest block machine in the world

2) It can make different style of soil interlocking bricks by changing molds

3) It does not need electricity, which is so good for block makers in the village

4) It needs few labor power to be operated, even the child can press it easily.

Features of HR1-30 brick machine (for sell)

1)Material hopper size.It can reserve 8-10 shift material.Sving feeding time and labor.

2)Material hopper with screw to be connected in order to Disassemble quickly

3)Molding box.With screw to be connected in order to change molding more easierly

4)Off molding hook.Patent design,saving time and labor

5"Longer arm.Shorten the lever stressing distance,saving labor force and offer more bigger pressure

6)Support.It makes machine stabilized,saving client investment

7)Molding pallet.With screw to be conected in oder to change molding more easierly

Brick machine showing

NOTICE:

1.The machine take use of steel casting molds,which are made by carburizing technology and heat treatment process,can enhance resistance of the mold, prolong the cycle life, and can keep the size of the brickconstant. you can

produce various size of brick by replacing molds, it is easy to use.

2.The machine is added with a track, bearing can move along the orbit, in

this way can save much labor.

our interlocking brick samples capacity

Capacity Table

| Block size | Pcs/mould | Pcs/hour | |

| 250x125x100mm | 2 | 180 | |

| 125x125x100mm | 4 | 360 | |

| 300x150x100mm | 2 | 180 | |

| 150x150x100mm | 4 | 360 | |

| 300x150x100mm | 1 | 60 | |

| 300x150x100mm | 1 | 60 |

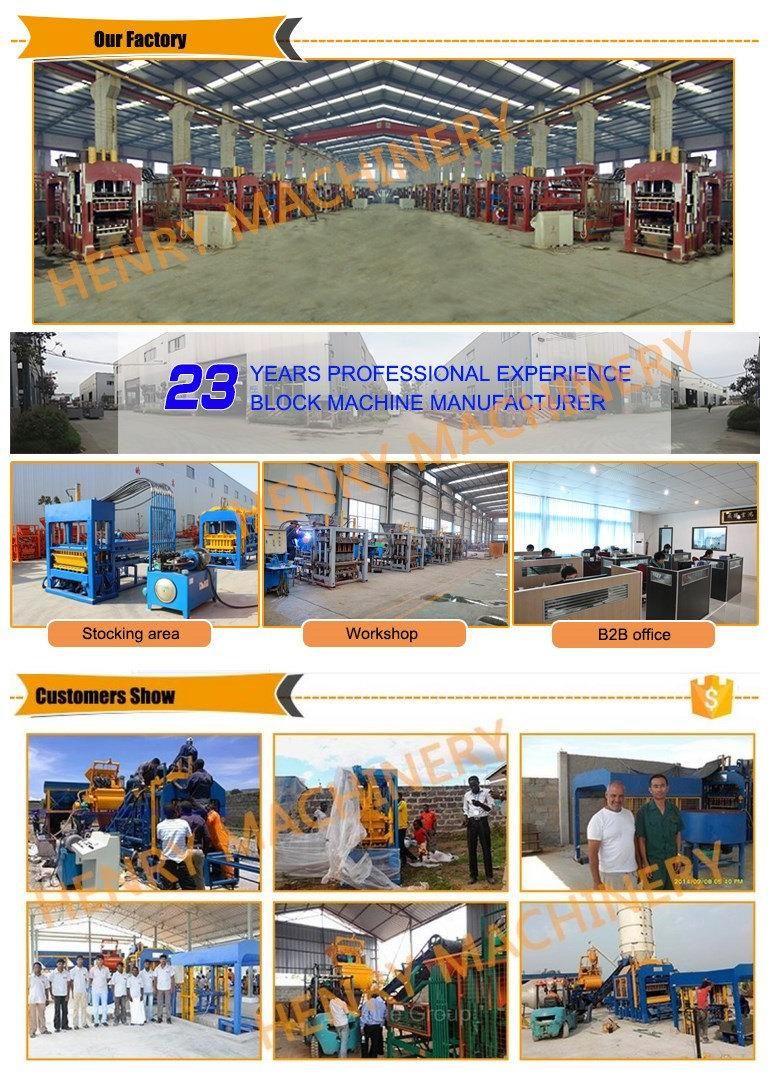

Company profile

Henry Industrial Co., Ltd has been committed to designer, manufacturer, saler of

construction machinery ,has the domestic advanced equipments, super professional skills. With over 23 years of experience, we produce a wide range of products like hollow block machine, soil brick machine, interlocking brick machine, paving machine, crusher, mixer,

block mould and paving mould.

Among the same trade, the company took the lead in wining the ISO9001 and ISO

14001environment management system certificate, CE certificate, the"China Well-Known

Trademark ", and "High and New Tech enterprise certificate" Our products have been

well sold to hundreds of countries and regions such as Europe, America, Africa, the

Middle east, Southeast Asia, etc, winning the high reputation of customers from domestic

and overseas.now has 3 offices in foreign countries.

We have powerful after-sale service team which composed of experience

technician. Among them, over 20 workers have the passport and oversea experience.

our service

We have go big after sale service team , they are all the experience technician ,

over 20 workers have the passport ,they all have the oversea experience.

So we not only have good service in the pre service , we also think highly of the

after sale service.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can make

inviation letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

Guarantee

(1)We can supply one year guarantee period for our brick making machines,if the

client have the question ,they could call our service department number any time,

we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client

place to help.