PLC Control Steel Frame Roll Forming Machine / C Purlin Cold Roll Forming Machinery

Cangzhou Nexus Machinery Co., Ltd.- Warranty:1 Year

- Certification:CE, ISO9001

- Customized:Customized

- Condition:New

- Control Type:Electric

- Automatic Grade:Automatic

Base Info

- Model NO.:NX80--300

- Product Name:PLC Control Steel Frame Roll Forming Machine

- Coil Material Thickness:1--3mm

- Processing Material:Galvanized Steel

- Roller Material:High Grade No. 45 Forged Steel

- Shaft Material:High Grade No. 45 Carbon Wrought Steel

- Cutting Blade:Cr12 Mould Steel with Quenched Treatment

- Diameter of Shaft:70mm or as Your Requirement

- Forming Steps:12 Rollers

- Productivity:15-25m,Min

- Hydraulic Station Power:22 Kw

- Transport Package:Plastic Film

- Specification:80-300

- Trademark:Nexus Machinery

- Origin:Cangzhou

- HS Code:8455221000

- Production Capacity:10

Description

Basic Info.

Model NO. NX80--300 Product Name PLC Control Steel Frame Roll Forming Machine Coil Material Thickness 1--3mm Processing Material Galvanized Steel Roller Material High Grade No. 45 Forged Steel Shaft Material High Grade No. 45 Carbon Wrought Steel Cutting Blade Cr12 Mould Steel with Quenched Treatment Diameter of Shaft 70mm or as Your Requirement Forming Steps 12 Rollers Productivity 15-25m/Min Hydraulic Station Power 22 Kw Transport Package Plastic Film Specification 80-300 Trademark Nexus Machinery Origin Cangzhou HS Code 8455221000 Production Capacity 10Product Description

PLC Control Steel Frame Roll Forming Machine / C Purlin Cold Roll Forming Machinery The advantages of PLC Control Steel Frame Roll Forming Machine / C Purlin Cold Roll Forming Machinery are as follows:

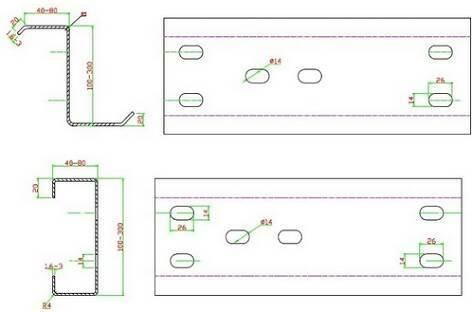

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

Echnical parameters of PLC Control Steel Frame Roll Forming Machine / C Purlin Cold Roll Forming Machinery :

Raw materialmaterial spec: sheet, galvanized steel sheet, aluminum sheet

thickness of coil sheet: 1.0-3.0 mm

material expand width:175-465mm

Machine details

roller material:High grade NO. 45 forged steel with 0.05mm hard chrome plating

shaft material:High grade NO. 45 carbon wrought steel

cutting blade:Cr12 mould steel with quenched treatment

diameter of shaft:70mm or as your requirement

forming steps:12 rollers

productivity:15-25m/min

hydraulic station power:22 KW

hydraulic pressure:10-12MPa

controlling system:famous PLC computer control

material of cutting table:Cr 12 mould steel with quenched treatment

appearance size:6100mm*1150mm*1510mm

hydraulic oil:40# hydraulic oil

Electric tension:380V 50 Hz 3 Phase or as your requirements

ABOUT US:

FAQ:

1. How long the machine could be made?- Normally speaking, light gauge steel frame machine could

be made without 45 working days. If you need machines in a hurry, we can make it for you

less than a month.

2. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours), then we can

pick up you.

3. Do you have after sales support?

-Yes, we are happy to give advice and we also have skilled technicians available across the

world.We need your machines running in order to keep your business running.