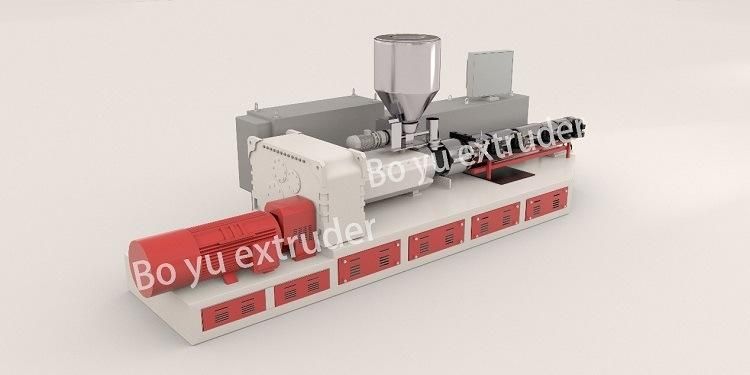

Imitation Marble PVC Board Production Line

Wuxi Boyu Plastic Machinery Co., Ltd.- Product Type:Extrusion Molding Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

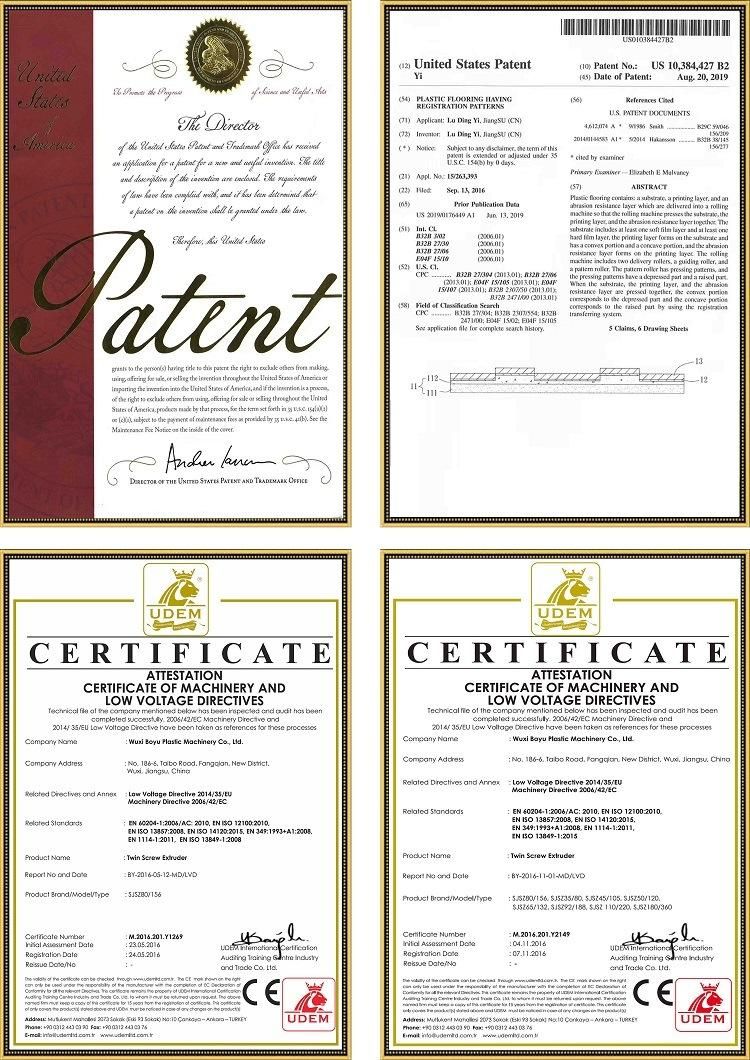

- Certification:CE, ISO

- Condition:New

Base Info

- Model NO.:BYSJ

- Customized:Customized

- Type:Sheet Extruder

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Packing by PP,PVC Film or Wooden Case

- Trademark:BOYU

- Origin:Wuxi China

- HS Code:8477209000

- Production Capacity:30 Machine Lines Per Month

Description

Basic Info.

Model NO. BYSJ Customized Customized Type Sheet Extruder Plastic Processed PVC Feeding Mode One Feed Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package Packing by PP/PVC Film or Wooden Case Trademark BOYU Origin Wuxi China HS Code 8477209000 Production Capacity 30 Machine Lines Per MonthProduct Description

PVC Imitation Marble Profile Extrusion Production LineI. Design parameters

| No. | Items | Data |

| 01 | Operation Conditions | 380V/3 phases/50Hz, DC24V. |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant |

| 04 | Main material proportion | PVC: CACO3= 1:3 |

| 05 | Product specifications | Width:1220mm,Thickness:1-8mm |

| 06 | Extrusion line mode | SJSZ 80/156 conical twin screw extrusion line |

| 07 | Quality standard | Twin screw standard JB6492-2001 Electricity standard: GB5226.1-2008/IEC 60204-1:2005 |

| 08 | Machine Fabrication Certificate | CE /UL |

| 09 | Electric components certificate | CE /UL /CSA |

II.Equipment List & Quantity

| No. | Equipment Name | Quantity | Remark |

| 01 | Φ80/156 Conical twin-screw extruder | 1 Set | |

| 02 | Extrusion die | 1 Set | |

| 03 | Three-rollers calender | 1 Set | |

| 04 | Film unwinding mechanism & magnetic powder controller | 1 Unit | For two working position |

| 05 | Oil rollers heating system | 1 Set | 4 units |

| 06 | Cooling bracket | 1 Unit | |

| 07 | Longitudinal edge cutting mechanism | 1 Unit | |

| 08 | Traction machine | 1 Set | |

| 09 | Length meter | 1 Set | |

| 10 | Plate shearing machine | 1 Set | |

| 11 | Automatic stacker | 1 Unit | |

| 12 | Electric control cabinet | 1 Unit |

III. Production process:

The screw feeder takes the material from the 5m3 silo(~ 3 tons) → The Extruder Feeding Hopper → The extruder → Material plasticizing → T-die → The Three-rollers Calender →Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Flipping & Stacking Machine

IV. Main technology parameter of extruder

- Conical Twin-screw Extruder

| Extruder Model | Capacity/24h | Capacity/h | 4mm Linear Speed |

| SZJZ-80 | 6-8T | 250-350KG | 0.4-0.6m/min |

| SZJZ-92 | 8-12T | 500-700KG | 0.8-1.3 m/min |

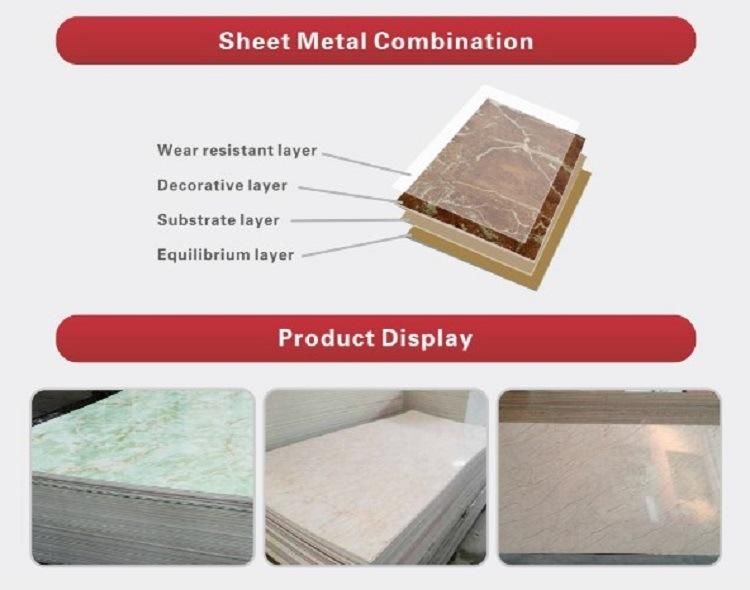

V. Finished Products

PVC imitation marble profile characteristics:

A, the surface is smooth, mirror effect;

B, the surface film color is rich, you will have more choices;

C, the material have no formaldehyde, surface color treatment without solvent and benzene;

D, because the color is hot stamping processing, surface is light oil processing, no color difference , have a good weatherability;

E, surface is UV processing, product is wear resistance and impact;

F, UV treatment surface is corrosion preventive.

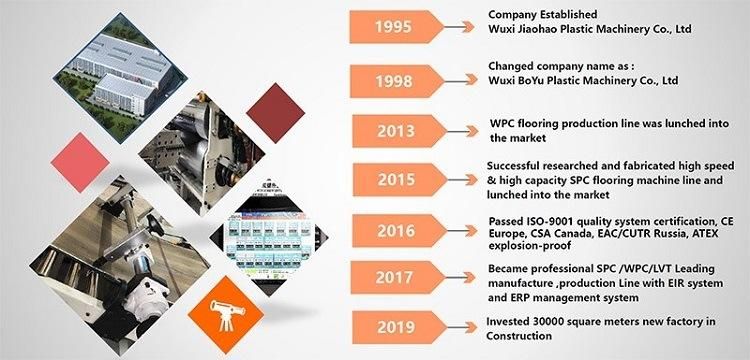

VI. Boyu Company Profile

VII. Our Services:

VIII. Shipping

IX. Patents