Galavinzed Color Double Corrugated Glazed Roofing Sheet Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Tile Type:Glazed Steel

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Usage:Roof

- Transmission Method:Machinery

Base Info

- Model NO.:Customized

- Transport Package:Nude

- Specification:CE SGS ISO

- Trademark:DIXIN

- Origin:Botou, Hebei, China

- HS Code:84552210

- Production Capacity:500 Sets,Month

Description

No.

Item

Specification

1

Can Formed Material

PPGI,GI,AI

2

Equipment operation

Automatic

3

Voltage

380V 60Hz 3Phase or as your requirement

4

Thickness of sheet (mm)

0.5-0.8mm

5

Material width(mm)

As your requirement

6

Cover Width of the sheet after formed

as your drawing

7

The size of the roll forming machine

6500mmx1600mmx1400mm

8

Speed

8-15m/min

9

Diameter of shaft

70mm

10

Weight of the Machine

6500-7000KGS

11

Material of rollers

C45 steel quenched and chromed

12

Motor brand

Siemens or Guomao

13

PLC

Siemens or Delta or Mitsubushi

14

Total power (kw)

12kw

15

Power of hydraulic system

7.5kw

16

Power of main molding core

4.5kw

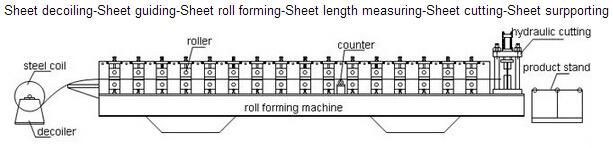

Working flow

1. Technology:We have centers and innovative designing teams for different kinds of production lines.

2. After Sale Service:Warranty period 1 year , after this period , we are willing to give help

if customer needs accessory . The real cooperation will not end at the delivery .

we believe that satisfied after sale service means a lot.

3. Inspected by the Sellers:After completing the manufacturing and assembling of the equipments,

we will test the machines and commissioning in the workshop.

4. Inspected by the Buyers:After confirmation of a sound work of the line,

we will invite our customer to send their representatives to inspect the production lines in our factories.

The management of the color steel cold roll forming machine is very important in the equipment management, which requires that the relevant staff fully understand the operating conditions and technical specifications of the cold bending machine. Do a good job of management and maintenance, and implement professional management methods, so as to truly realize the standardization of equipment management for cold bending forming machines.

In general, the management of Color Steel Roll Forming Machine has the following requirements:

1. Cleaning: The internal and external surfaces of the cold roll forming machine are clean and tidy, there is no oil contamination between the various components, and the surrounding impurities and dirt must be cleaned;

2, neat: After entering the market to be placed in the horizontal position, the line should be organized;

3. Safety: Obey the safety operation specification, and do not use the equipment of the cold bending forming machine. The safety protection device is complete and reliable, and attention should be paid to eliminating unsafe factors in time.

4, Maintenance: Do a good job of daily maintenance work, without permission without permission to disassemble parts and components, found abnormal cold bending machine should immediately stop working, timely troubleshooting and propose solutions, does not allow sick operation.

Packaging & Shipping

1.Packaging Details:Nude,with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

2.Port:TIANJIN XINGANG PortLead .

3.Time: Shipped in 35 days after payment.

Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What's the delivery time?

A:Normaly will take 60days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we're always here for giving you advice and support for technical details since we have senior technician. Our 24-in-service number is 0086-15131782831

Q:Is there quality control when manufacturing the lines?

A:Yes, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging.

Q:What's your strength comparing to the other supplier?

A:We'll supplying you the best quality and service. We'll give you good advise beyond your requirements. The lines are easily for installation and with low mantenance requirements.