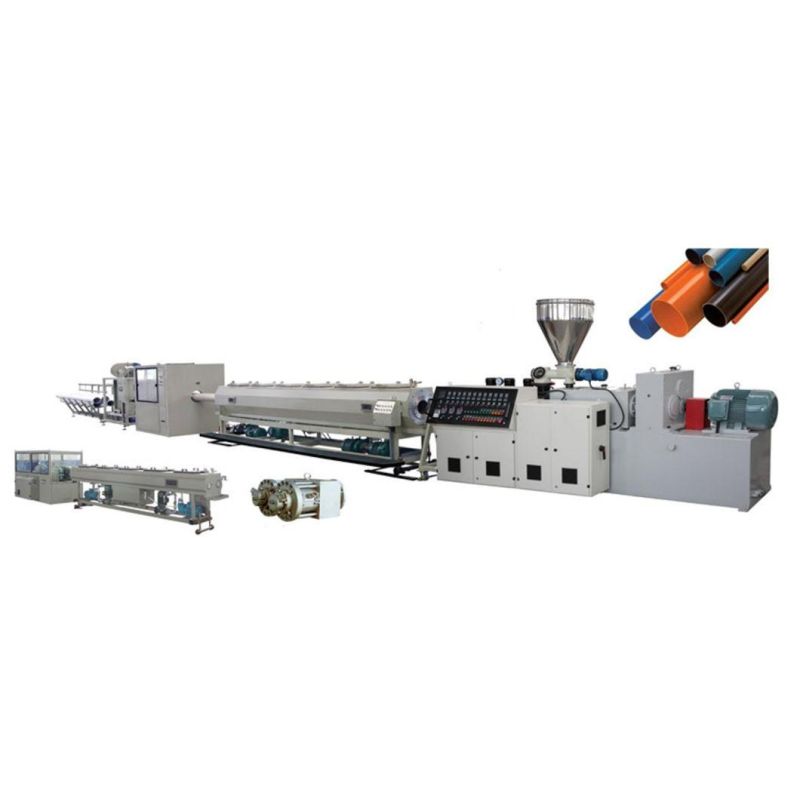

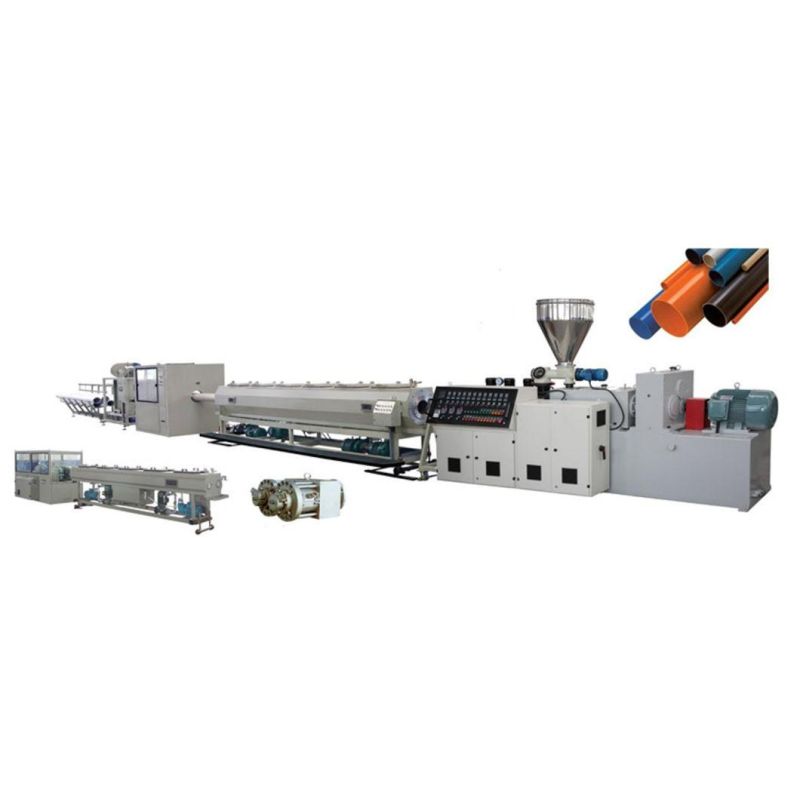

PE PP Pipe Making Machine

Suzhou Lianguan Machinery Co., Ltd.- After-sales Service:Warranty 12 Months

- Warranty:Warranty 12 Months

- Pipe Material:PP PE

- Condition:New

- Customized:Customized

- Theory:Inverter

Base Info

- Application:Produce PE PP PPR Pipe

- Type:Pipe Production Line

- Certification:ISO, Ce

- Pipe Range:16-630mm

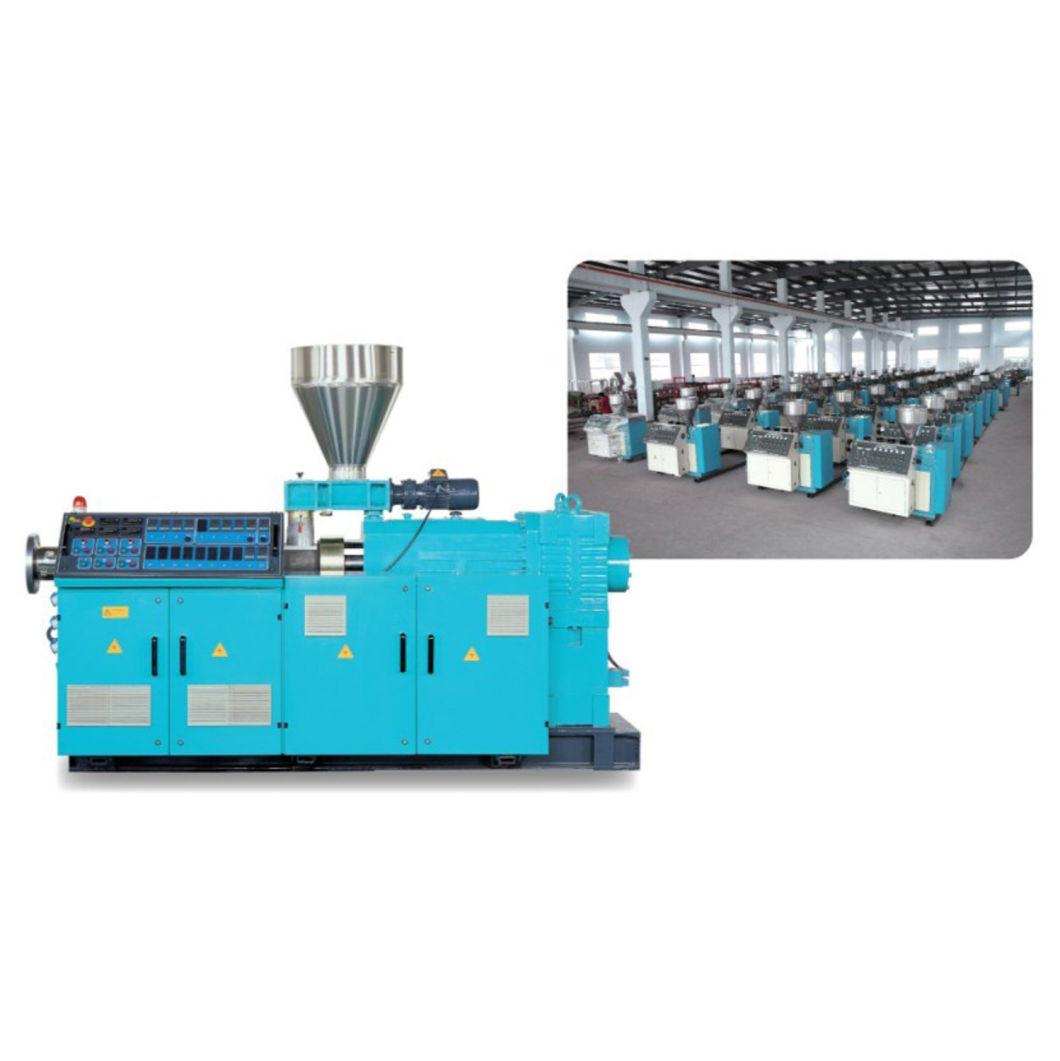

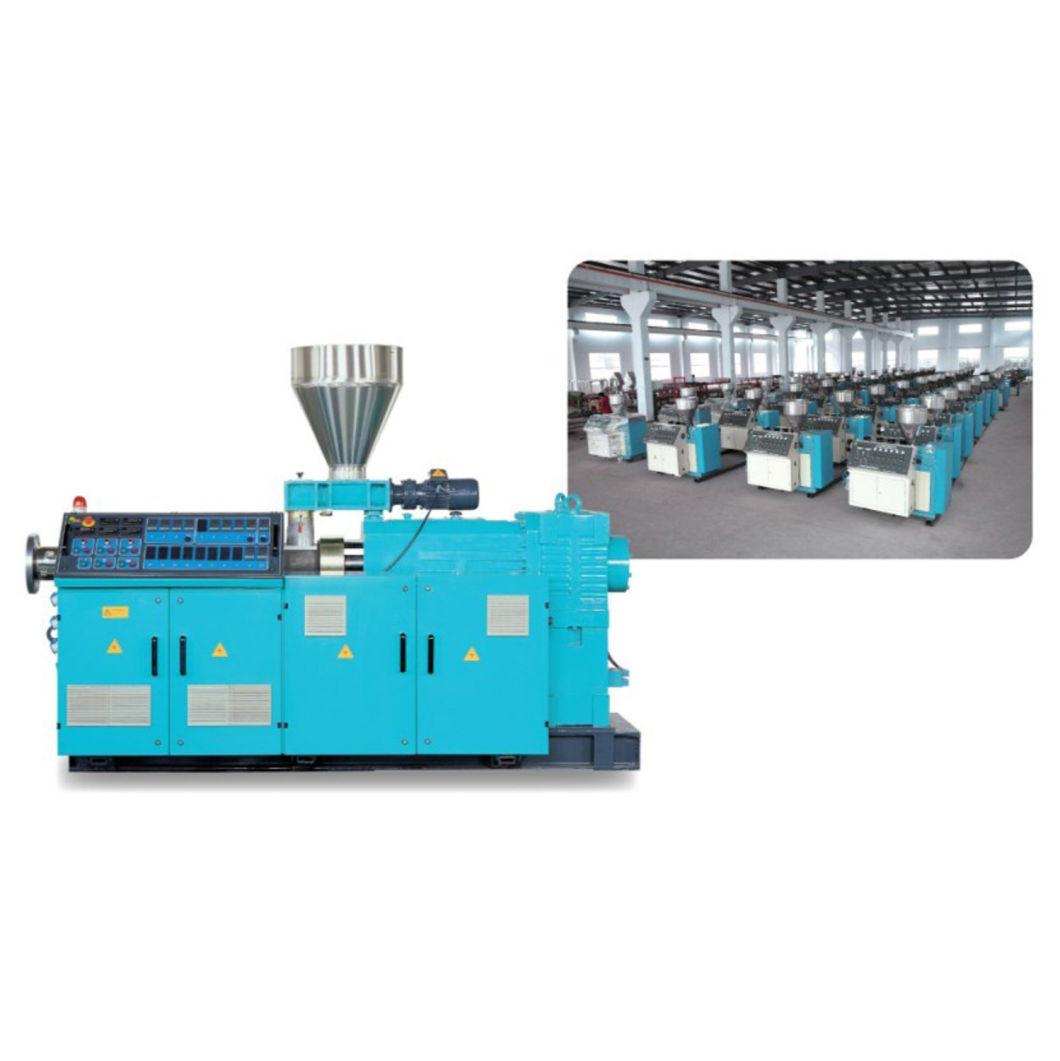

- Extruder:Single Screw Extruder

- Speed Control:AC or DC Inverter

- Motor:AC or DC Motor

- Voltage:380V or According to Requirement

- Transport Package:Wooden Box Film

- Trademark:lianguan

- Origin:China

- Production Capacity:5 Sets Per Month

Description

SJPG120/33 single screw extruderPLC control 1 DC motor model Z4-280-32 2 DC motor power 280KW 1500r/min 3 Reducer model ZLYJ420B-12.5-VI-T 4 8"liquid crystal display Siemens 5 Screw diameter ∮120mm 6 Screw ratio 33:1 7 Screw material High quality alloy steel 38CrMoA1A 8 Structure High efficiency 9 Screw revolving speed (r/min) 10~120r/min 10 Speed adjustment mode Dc speed governing 11 Governor brand UK oulu 12 Barrel heating zone 7 13 Die head heating zone 23 14 Barrel cooling method Air cooling 16 Heating ring material and quantity Cast aluminum , 7unit 17 Centrifugal fan quantity and power 0.55KW×7 18 Water cycle cooling system Water 19 Auxiliary equipment 400kg/h Drying machine 1set

1000kg vacuum feeding 1set 20 Drying machine and barrel connect method Directly 21 Suitable pipe range ∮315~∮630mm 22 Maximum capacity 650~850kg/h(HDPE) 23 Equipment center height 1250±50mm 24 Melt pressure senor 25 Main low-voltage apparatus Schneider 26 Electrical control box install method External SJPG25/20 Single screw marking extruder 1 Main motor power 1.5KW 2 Reducer power and ratio 1.5kw i=187 3 Screw diameter ∮25mm 4 Screw ratio 20:1 5 Screw material High quality alloy steel 38CrMoA1A 6 Speed adjustment method Frequency control 7 Transducer brand ABB 8 Barrel heating zone 2 9 Machine heating zone 1 10 Temperature controller Japan Omron 11 Main low-voltage apparatus Schneider 12 Maximum capacity 5kg/h(HDPE) 1 Vacuum tank type Double chamber 2 Vacuum tank length 11000mm(2700+8300) 3 Pipe suitable range Φ315-Φ630mm 4 Water-ring vacuum pump quantity 3 5 Water-ring vacuum water pump power 5.5kw+5.5kw×2 6 Centrifugal pump quantity 3 7 Centrifugal pump power 5.5kw+ 7.5kw×2 8 Pipe install method Two way inflow, two way drain 9 Water pump sealing ring Mechanical sealing 10 Moving motor power 1.5KW×1 11 Shifting method Lead screw 12 Forward backward shifting range ±500mm 13 Left right shifting range ±60mm 14 Center height 1300±50mm 15 Tank material 304 stainless steel 16 Cover thickness 5mm 17 Cover material Toughened glass cover 18 Cover quantity 7 19 Cooling method Spray 20 Cooling medium Water 21 Spray pipe quantity 10 22 Spray nozzle quantity 680 23 Spray nozzle specification New type 24 Vacuum pump gas water separator device 3 25 Water tank filter device 26 Flow meter device 6 27 Filter 3 28 Pipe holding method Supporting plate, quantity 8 29 Exit sealing plate ∮315,∮400,∮450,∮500,∮630 30 Tank fastener material Stainless steel 31 Tank liquid level control Water temperature and level control 32 Water pump inflow pipe diameter 3" 33 Drain pipe diameter 3" 34 Inflow pipe diameter 1" 35 Tank structure Polygon round PL-630 Spray cooling tank 1 Spray cooling tank length 5800mm 2 Suitable pipe range Φ315-Φ630mm 3 Tank material Stainless steel and toughened glass window 4 Plate thickness 3mm 5 Center height 1300±50mm 6 Centrifugal pump quantity 2 7 Centrifugal pump power 5.5KW 8 Cooling method Spray 9 Cooling medium Water 10 Spray pipe quantity 8 11 Spray nozzle quantity 288 12 Spray nozzle specifications New type nozzle 13 Pipe holding method Nylon roller 14 Roller height adjustment 15 Pipe outside tank material Stainless steel 16 Sealing device Sealing plate, rubber 17 Water pump inflow pipe diameter 3" 18 Inflow pipe diameter 1.5" 19 Spilled water pipe diameter 3" 20 Circular SJAY-630 Six-claws Haul-off machine 1 Tracking type Six claws 2 Tracking caterpillar rubber 3 Rubber size(length×width×height) 95×43×35mm 4 Rubber quantity 112×6=672 5 Equipment center height 1300±50(mm) 6 Suitable pipe range Φ315-Φ630mm 7 Maximum tracking speed 0.1~1.0m/min 8 Maximum tracking force 60KN 9 Maximum compact force 6KN 10 Compact force adjustment Pneumatic 11 Caterpillar contact length 2450mm 12 Tracking direction Forward 13 Motor power 1.1KW×6 14 Lifting motor power 0.75KW 15 Caterpillar opening degree 730mm 16 Compressed air pressure 0.4-0.6Mpa 17 Work piece shape Round tough pipe 18 Up Caterpillar lifting method Air cylinder 19 Down Caterpillar lifting method Gear box(quantity:6) 20 Impact air cylinder quantity 6 21 Impact air cylinder specification ∮160 22 Caterpillar chain pitch P25.4 23 Caterpillar chain quantity 224 24 Clamping block install Screw 25 Length measurement Rotary encode 26 Speed control Frequency control 27 Transducer brand ABB 28 Electrical control box install method Infront of equipment HSQ-630 hydraulic planet cutting machine 1 Cutting type Hydraulic planet cutting 2 Cutting range Φ315-Φ630mm 3 Center height of cutter 1300±50mm 4 Turn table period 0.4~3cr/min 5 Cutting opening degree ∮730mm 6 Track maximum distance 1200mm 7 Moving air cylinder quantity ∮63×1200mm 8 Maximum cutting thickness 60mm 9 Revolution motor power BYD series power:2.2kw 10 Reducer BWD series ratio:1:43 11 Cutter motor power Y series power:4.0kw 12 Suction fan power 1.5kw 13 Hydraulic feeding motor power 0.55kw 14 Cutting method saw, manual/auto 15 Blade feeding method hydraulic 16 Saw specification ∮300×∮30 17 Saw adjustment Lead screw with shield 18 Hydraulic cylinder diameter ∮50×80mm (quantity 1) 19 Revolution speed Frequency control 20 Transducer brand ABB 21 Clamping Air cylinder 22 Air cylinder specifications ∮80×60mm (quantity:4) 23 Aluminum clamp specification Φ315,Φ400,Φ450,Φ500,Φ630 24 Pipe holding method Nylon roller 25 Brush T102-6×12 26 Electrical control mode PLC 27 Electrical control box install method Internal 28 Main low-voltage apparatus Schneider GLFL-630 Roller turning stack 1 Length 6000mm 2 Control method PLC 3 Rolling method pneumatic

1000kg vacuum feeding 1set