Sizes Changeable Stud Track Roll Forming machine Drywall for Steel Framing House

Frametec (Xiamen) Building Technology Co., Ltd.- After-sales Service:Engineers Oversea Support

- Warranty:1 Year

- Certification:CE, ISO9001, Icc, CSA, Saber & etc

- Customized:Customized

- Condition:New

- Control Type:CNC

Base Info

- Model NO.:MF1600

- Automatic Grade:Automatic

- Feeding Material:Galvanized Sheet(Gi), Cold Roll Steel(CRC), Hot RO

- Yield Strength:235-550MPa

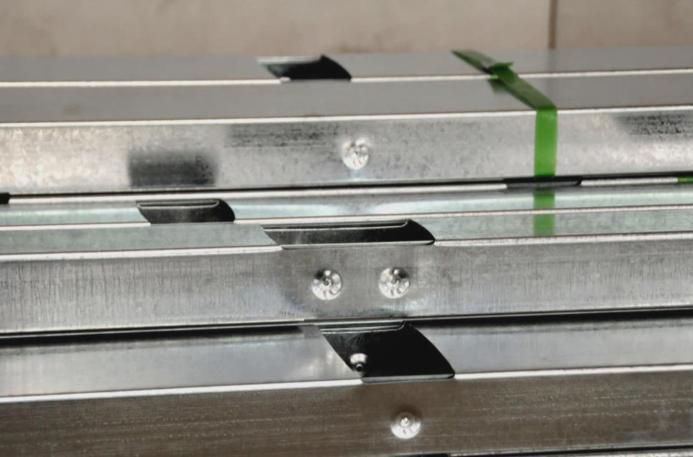

- Punching:Service Hole, Dimple Hole, Web Notching

- Thickness:0.75-1.6mm

- Profile Width:75mm-160mm

- Profile Flange:41mm

- Profile Lip:8mm -15mm

- Cutter Material:Cr12 MOV, Heat Treatment

- Control System:PC Control

- PLC Brand:Japan Panasonic

- Decoiler:Hydraulic Decoiler

- Forming Stage:17 Stations

- Size Changing:Auto Size Changing for Rollers

- Blade Replacement:Manual Blade Replacing

- Main Motor Power:15kw

- Transport Package:Naked Package

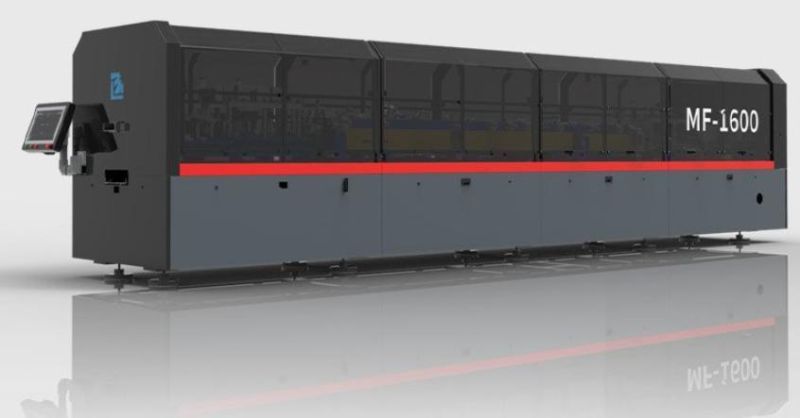

- Specification:length x width x height 13m x 1.2m x 1.6m

- Trademark:Frametec

- Origin:Xiamen, China

- HS Code:84552210

- Production Capacity:600 Sets,Year

Description

Basic Info.

Model NO. MF1600 Automatic Grade Automatic Feeding Material Galvanized Sheet(Gi), Cold Roll Steel(CRC), Hot RO Yield Strength 235-550MPa Punching Service Hole, Dimple Hole, Web Notching Thickness 0.75-1.6mm Profile Width 75mm-160mm Profile Flange 41mm Profile Lip 8mm -15mm Cutter Material Cr12 MOV, Heat Treatment Control System PC Control PLC Brand Japan Panasonic Decoiler Hydraulic Decoiler Forming Stage 17 Stations Size Changing Auto Size Changing for Rollers Blade Replacement Manual Blade Replacing Main Motor Power 15kw Transport Package Naked Package Specification length x width x height 13m x 1.2m x 1.6m Trademark Frametec Origin Xiamen, China HS Code 84552210 Production Capacity 600 Sets/YearProduct Description

Technology Parameters

The weight of the Machine: About 10.0T

The total dimension with un-coiler, Out-let Table is:

(length) 16m x (width) 1.71m x (height) 2m.

The dimension of forming parts: (length) 8m x (width) 1.71m x (height) 2m.

1) De-coiler

- De-coiler Type: Hydraulic auto de-coiler

- Weight capacity: Max 3.0T

- Diameter of inner: 480-510mm

- Diameter of outer: 800mm

- Motor power: 3.0Kw,60Hz, 380V(Customized)

- Control type: Electric button control

- Function: Auto rotation feed sheets into roll forming parts. Semi auto for loosening and tightening coil

- Weight of de-coiler: 1000KGS.

- Side Locks provided on de-coiler to fix coil.

2) Guiding: Guiding device is used to guide and fasten the raw material raw material into roll forming station steadily.

- Number of guide roller: 12, left side 6, right side 6.

- Guide roller material: GCr15

- Main motor type: 3 phases

- Main motor power: 15Kw, 60Hz, 380V (suits Australian power requirements)

- Servo motor brand: INNOVANCE

- Speed of forming: 25m/min

- Comprehensive speed: 5-12m/min

- Roller: 17 groups rollers. Roller Material is Cr12 mould steel being quenched treatment, with digital-controlled procession. This ensure rollers are all on good condition and long life.

- Shaft & Frame: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

- The frame is designed as strong as its required to bear the whole rollers and shafts. This ensure machine can work in long life without repairing any shafts and frames.

Material of main shaft: 40Cr. - Machine frame

- Material of frame: 45# steel

- Flare control rollers

- Flare device is made of two group rollers (each group has 4 rollers) with manual adjusting device. This type of device is used to straighten the shape of products. to ensure the length precision.

Changing sizes: Full-automatic (change sizes by PC control system) - Machine is designed to change profile size within 1 minutes. This type of system is easy to operate. Only need to set the profile specs on the control panel, the roller stands will move in and out automatically

4) Shaft & Frame:

4) Shaft & Frame:- Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

- Diameter of main shaft: ø65mm

Material of main shaft: 40Cr. (The main shaft have the high frequency grinding &heat Treatment and the surface of shaft is electroplated.

HRC28-32

5) Bearing: NTN brand from Japan.6) Machine Frame

The frame of machine are designed as square tube shape and thickness of frame is 30mm in order to make sure the machine is capable to bear all accessories of this machine.

- Machine frame basis is adopt H beam welding steel

- Material of up frame: 45# steel

- Material of bottom frame: Q235 steel.

- To assure the high precision of size changing, all basis of machine frame are installed linear guideway with high quality. Totally 4 groups.

- Brand of linear guideway: PIM from Taiwan.

Flare device is made of two group rollers (each group has 2 rollers) with manual adjusting device, this type of device is used to straighten the shape of products to ensure purlin are not bending.

8) Hydraulic Punching

- All punching dies are made from Cr12. Driven by hydraulic station. Holes locations are able to set by PC panel, including Punching length and numbers.

- Four leveling devices is used to fasten the raw material. When punching system is on working, the raw material will be fixed tightly by leveling device to ensure the job precision.

- Punching station: standard 2 stations (Customized by customer) .These 2 stations are capable to make dimple, service hole. Punching precision within +/-0.5mm. After punching, Stud or Track profile will be driven into cutting system.

- After punching, the cutter will shear the raw material automatically, driving raw material out of roll forming system.

- Shearing type: Hydraulic shearing with guillotine cutting.

- Blade hardness: HRC 58-60

- Working life: 30, 000 times to process once.

- Hydraulic motor power: 7.5KW, 380V, 60Hz

- Hydraulic oil box capacity: 200 litre

- Hydraulic solenoid valve: Huade or Yuken

4 meter material receiving table, with a C stud & Track stacking platform.

12) Safety Guard: Safety Guard covers the whole machine to ensure worker's safe.

There are 3 emergency stop buttons along the production line which are able to stop machine whenever any errors or emergency happens.

14) PC control system LG-R300.

- The control system MF 200 is able to program production CNC by inputing Dahe's TXT or CSV format and connect with machine directly. It can control machine auto-running and running status dynamically, including punching, cutting and size changing.

- Manual length/punching program for production

- The computer can control production line including leveling, punching, cutting, conveyer table and roll forming station. Speed of the machine can be adjusted.

- The choice production data can be showed on screen.

15) PLC Control System & Components

- Control the quantity & punching length & cutting length automatically

- The Machine will be stopped while it is punching and cutting

- Automatic Length measures and quantity counting (precision +- 0.5mm)

- Encoder : Omron

- Relays: Schneider

- Approaching switch: Schneider

- PLC manufacturer: Panasonic

- Control type:Win8 system or above with Dahezb NC control software.

- Hydraulic pump hydraulic valve with cooling system to cool hydraulic oil.

- Online inkjet marking system. Online printer can printer marks on the flange of both side.

16) Profile image and application

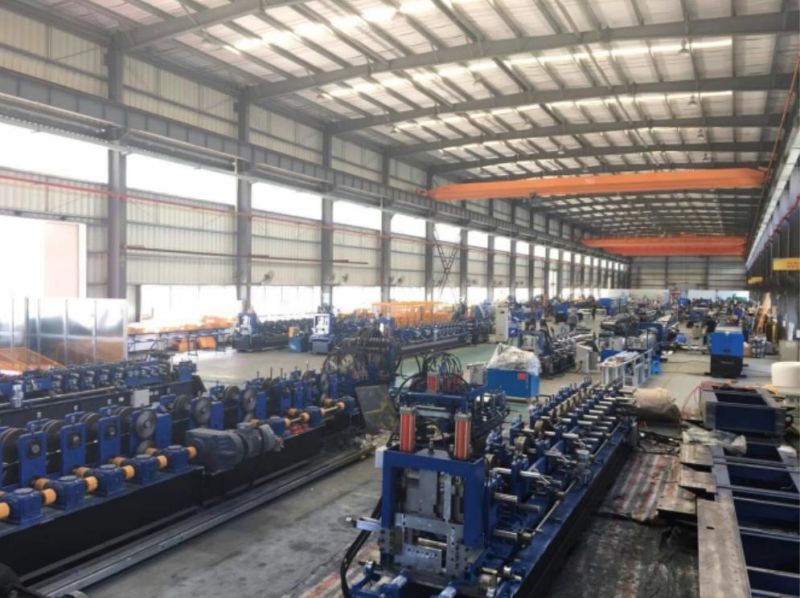

Our Factory

Why Choose us:

13+ years manufacturing experience in CZ purlin roll former

Competitive price and good quality

One year free warranty

Fast response of after sale service

Auto web size changing from 80mm to 350mm in 2 minutes

Can be customized by clients' requirements

Easy operate and easy to maintain

Self-developed of post cutter, one blade to cutter all size of final products